Anti-icing coating for low-temperature high-humidity environment and preparation method of anti-icing coating

A low-temperature, high-humidity, anti-icing technology, applied in the field of coatings, can solve the problems of poor surface durability of the coating, loss of anti-icing performance of the coating, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046]The preparation method of the functional porous nanomaterial is as follows: adding 100 g of an ethanol solution into a container, feeding nitrogen as a protective gas, and dispersing 5-10 g of an organic metal alkoxide together with 40-45 g of a low surface energy modifier in the container. In the ethanol solution, ultrasonically disperse uniformly, add porous nanomaterials with a mass of 40% to 50% of the mass of the low surface energy modifier, continue to ultrasonically disperse uniformly, and then place it in a vacuum oven at a temperature of 60 °C to dry, that is, to obtain functional Porous nanomaterials; the organic metal alkoxide is any one of ethylene glycol aluminum salt, isopropoxide aluminum salt, n-hexyl aluminum salt; the low surface energy modifier is perfluorosilane, perfluorooctanoic acid, perfluorooctanoic acid, perfluorooctanoic acid, perfluorooctanoic acid, perfluorooctanoic acid Any one of fluoroethylene propylene copolymer; the porous nano material i...

Embodiment 1

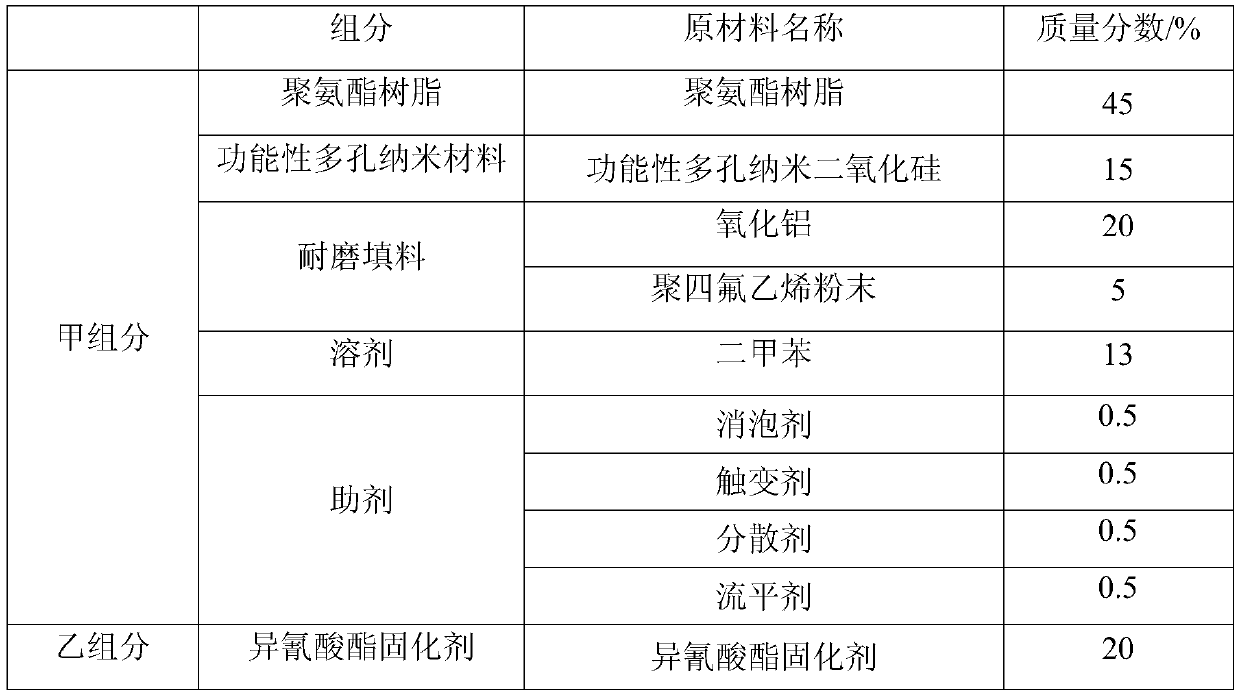

[0055] An anti-icing coating for a low temperature and high humidity environment, the components and corresponding mass fractions are shown in Table 1.

[0056] Table 1 Components of the anti-icing coating of Example 1 in terms of mass fraction

[0057]

[0058] The preparation method of the anti-icing coating comprises the following steps:

[0059] Step 1. Add 100g of ethanol solution to the three-necked flask, pass nitrogen as a protective gas, put 5g of ethylene glycol aluminum salt and 45g of perfluoroethylene propylene copolymer into the ethanol solution, after ultrasonic dispersion is uniform, add 22.5g of porous Nano-silica, after continuing to ultrasonically disperse for 2 hours, dry in a vacuum oven at 60 °C to obtain functional porous nano-silica;

[0060] Step 2: The elastic polyurethane resin, additives, 70% of the total solvent, and the functional porous nano-silica prepared in step 1 are weighed into the bucket according to the formula, and stirred for 5 minu...

Embodiment 2

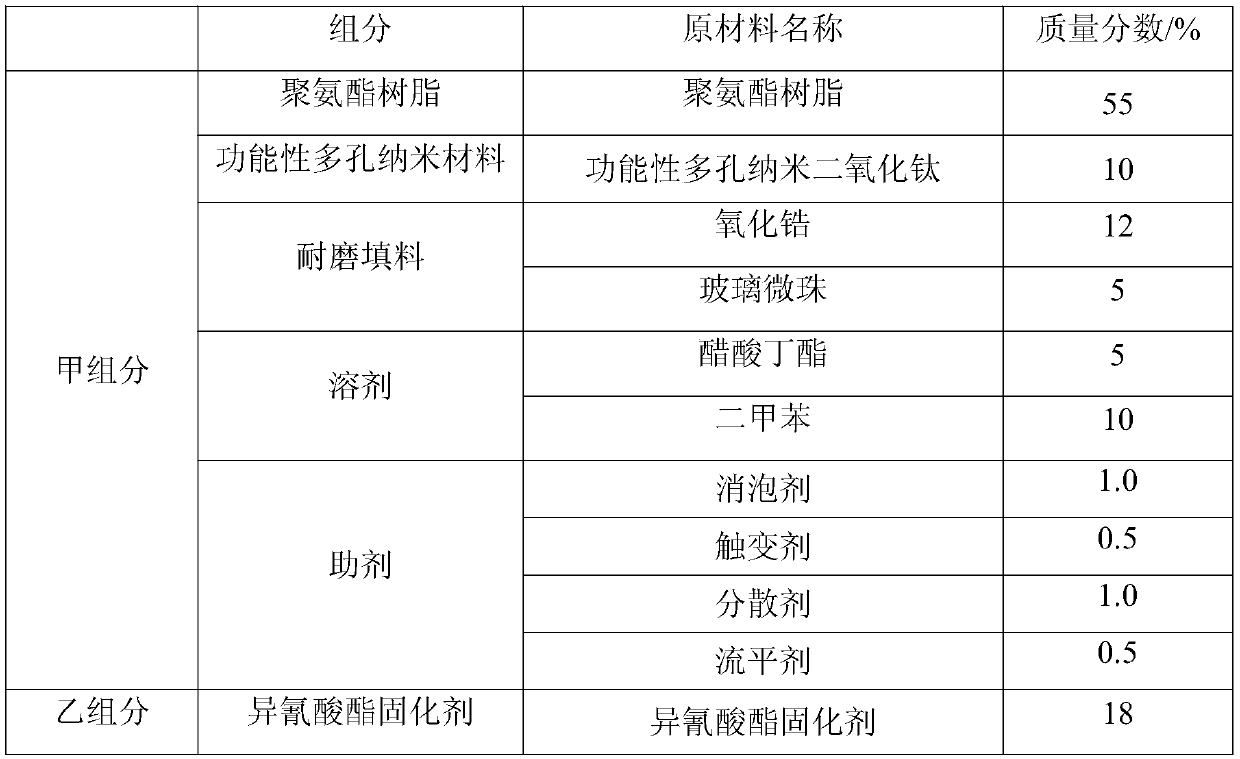

[0064] The components and corresponding mass fractions of the anti-icing coating in Example 2 are shown in Table 2.

[0065] Table 2 Components of the anti-icing coating of Example 2 by mass fraction

[0066]

[0067] The preparation method of the anti-icing coating comprises the following steps:

[0068] Step 1. Add 100g of ethanol solution to the three-necked flask, pass nitrogen as a protective gas, put 10g of aluminum isopropoxide and 40g of perfluorooctanoic acid in the ethanol solution, after ultrasonic dispersion is uniform, add 16g of porous nano-titanium dioxide, and continue to ultrasonically disperse After 2 h, drying in a vacuum oven at 60 °C to obtain functional porous nano-titanium dioxide;

[0069] Step 2, add the elastic polyurethane resin, auxiliary agent, solvent accounting for 70% of the total amount and the functional porous nano-titanium dioxide prepared in step 1 into the bucket according to the formula, and stir for 30min with a high-speed disperser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com