Preparation method of adjustable solid-state fluorescent carbon dots

A technology of solid-state fluorescence and carbon dots, applied in chemical instruments and methods, nano optics, luminescent materials, etc., can solve the problems of complex synthesis process, increased synthesis cost, low photoluminescence quantum yield, etc., and achieve simple preparation method, The effect of convenient raw material supply and convenient purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing adjustable solid-state fluorescent carbon dots for LEDs, the steps of which are:

[0036] (1) Add 0.15 mmol of dithiosalicylic acid to 10 mL of saturated acetic acid aqueous solution (36 wt.%), and ultrasonically mix for 10 minutes;

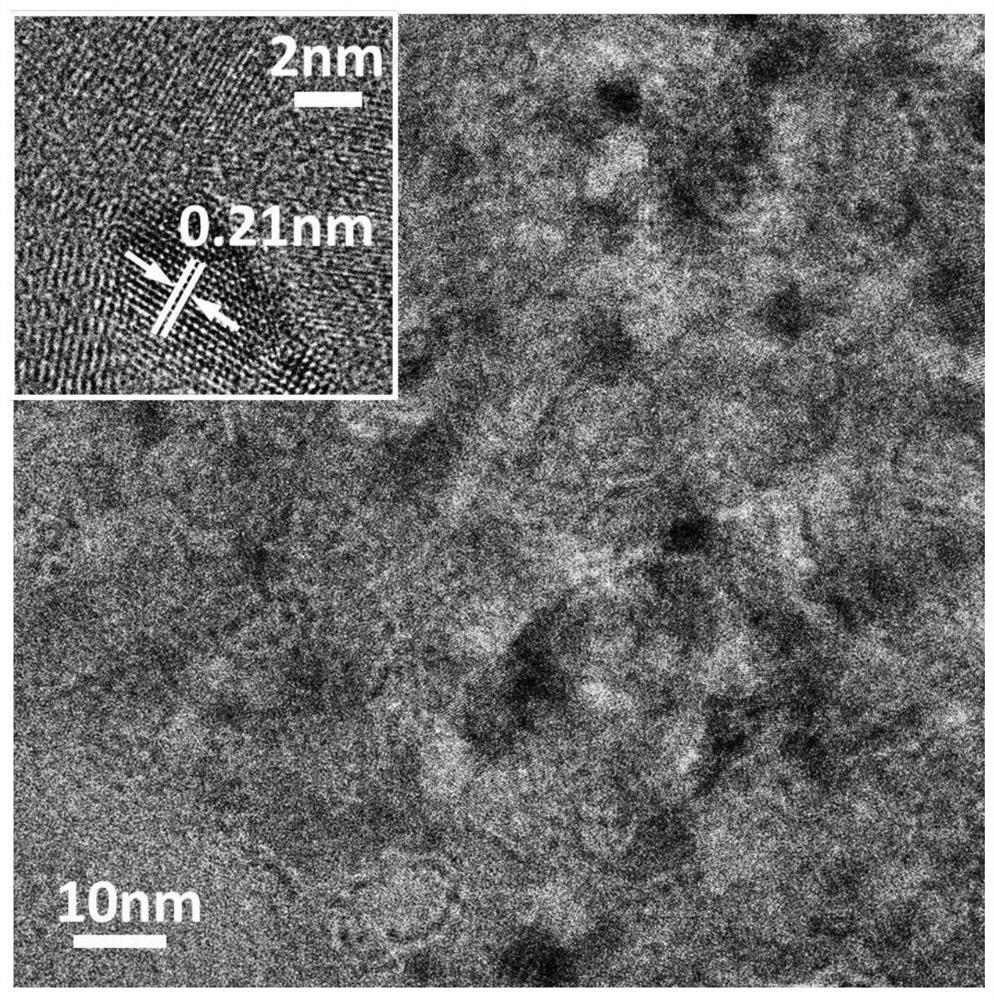

[0037] (2) Transfer the sonicated solution into a 50mL and tetrafluoroethylene liner, react in the reactor at 180°C for 15h, cool down to room temperature naturally after the reaction, add deionized water into the reacted solution, and the solution becomes cloudy rapidly , the turbid solution was centrifuged at a speed of 6500 rad / min for 10 minutes, and the supernatant was removed to obtain a precipitate. Repeat this process 2-3 times to obtain purified carbon dots. The purified carbon dot precipitate mixed with a small amount of solution was frozen in a refrigerator at -20°C until the solution became solid, and the solid was placed in a freeze dryer for 24 hours to obtain dry carbon dot powder.

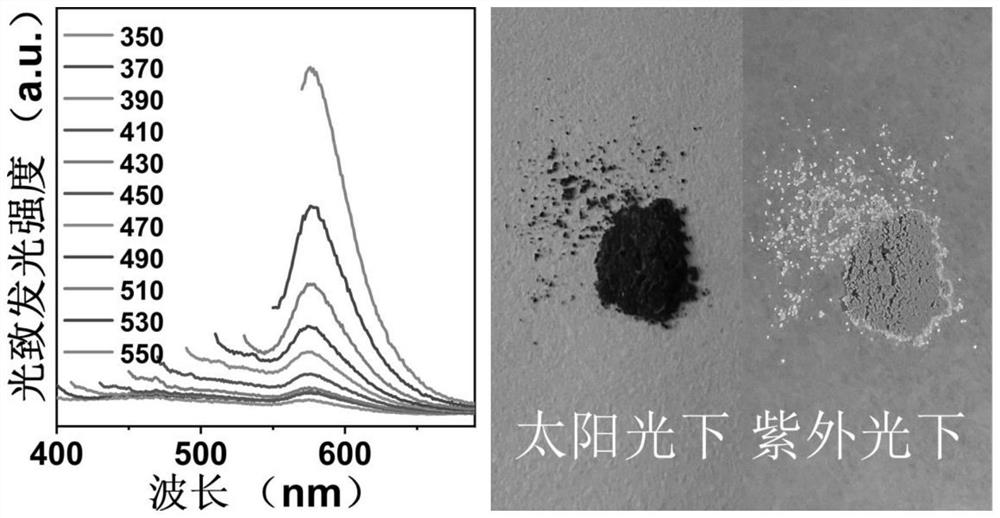

[0038] (3) Dispe...

Embodiment 2

[0040] (1) Add 0.5 mmol of dithiosalicylic acid to 10 mL of saturated aqueous acetic acid solution (36 wt.%), and ultrasonically mix for 10 minutes;

[0041] (2) Transfer the sonicated solution into a 50mL and tetrafluoroethylene liner, react in the reactor at 180°C for 15h, cool down to room temperature naturally after the reaction, add deionized water into the reacted solution, and the solution becomes cloudy rapidly , the turbid solution was centrifuged at a speed of 6500 rad / min for 10 minutes, and the supernatant was removed to obtain a precipitate. Repeat this process 2-3 times to obtain purified carbon dots. The purified carbon dot precipitate mixed with a small amount of solution was frozen in a refrigerator at -20°C until the solution became solid, and the solid was placed in a freeze dryer for 24 hours to obtain dry carbon dot powder.

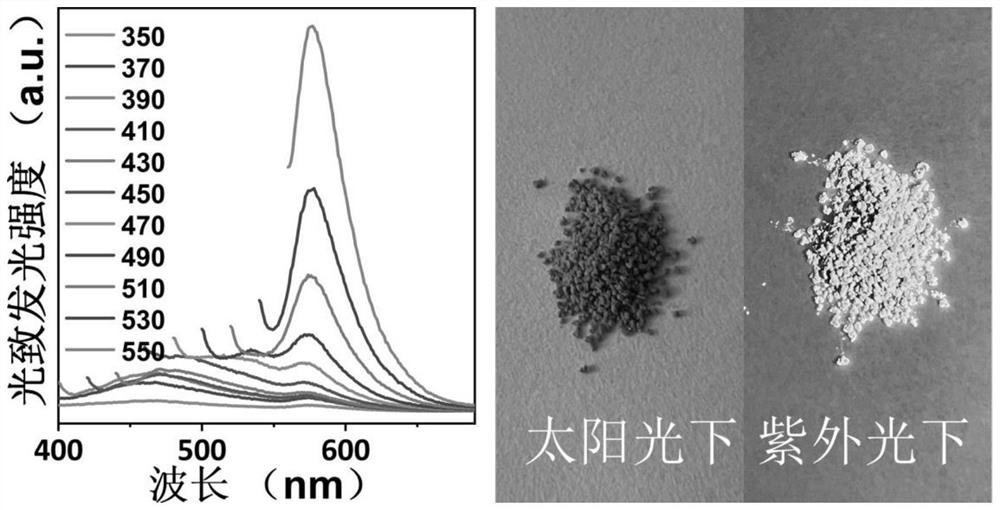

[0042] (3) Disperse 0.2 g of the purified carbon dots in 3 mL of toluene solution mixed with 1 g of polystyrene, and stir at 60° C....

Embodiment 3

[0044] (1) Add 1 mmol of dithiosalicylic acid to 10 mL of saturated aqueous acetic acid solution (36 wt.%), and ultrasonically mix for 10 minutes;

[0045](2) Transfer the sonicated solution into a 50mL and tetrafluoroethylene liner, react in the reactor at 180°C for 15h, cool down to room temperature naturally after the reaction, add deionized water into the reacted solution, and the solution becomes cloudy rapidly , the turbid solution was centrifuged at a speed of 6500 rad / min for 10 minutes, and the supernatant was removed to obtain a precipitate. Repeat this process 2-3 times to obtain purified carbon dots. The purified carbon dot precipitate mixed with a small amount of solution was frozen in a refrigerator at -20°C until the solution became solid, and the solid was placed in a freeze dryer for 24 hours to obtain dry carbon dot powder.

[0046] (3) Disperse 0.2 g of the purified carbon dots in 3 mL of toluene solution mixed with 1 g of polystyrene, and stir at 60° C. fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com