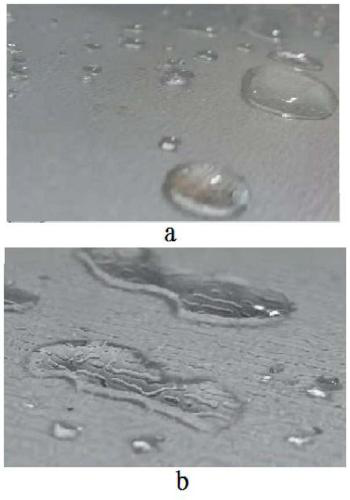

Whisker-reinforced hydrophobic nylon 66 composite material and preparation method thereof

A composite material and hydrophobic technology, which is applied in the field of nylon engineering plastics, can solve the problems that affect the dimensional stability and strength of products, expansion, nylon 66 is easy to absorb water, etc., and achieve the value of extensive large-scale promotion of production, simple preparation process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

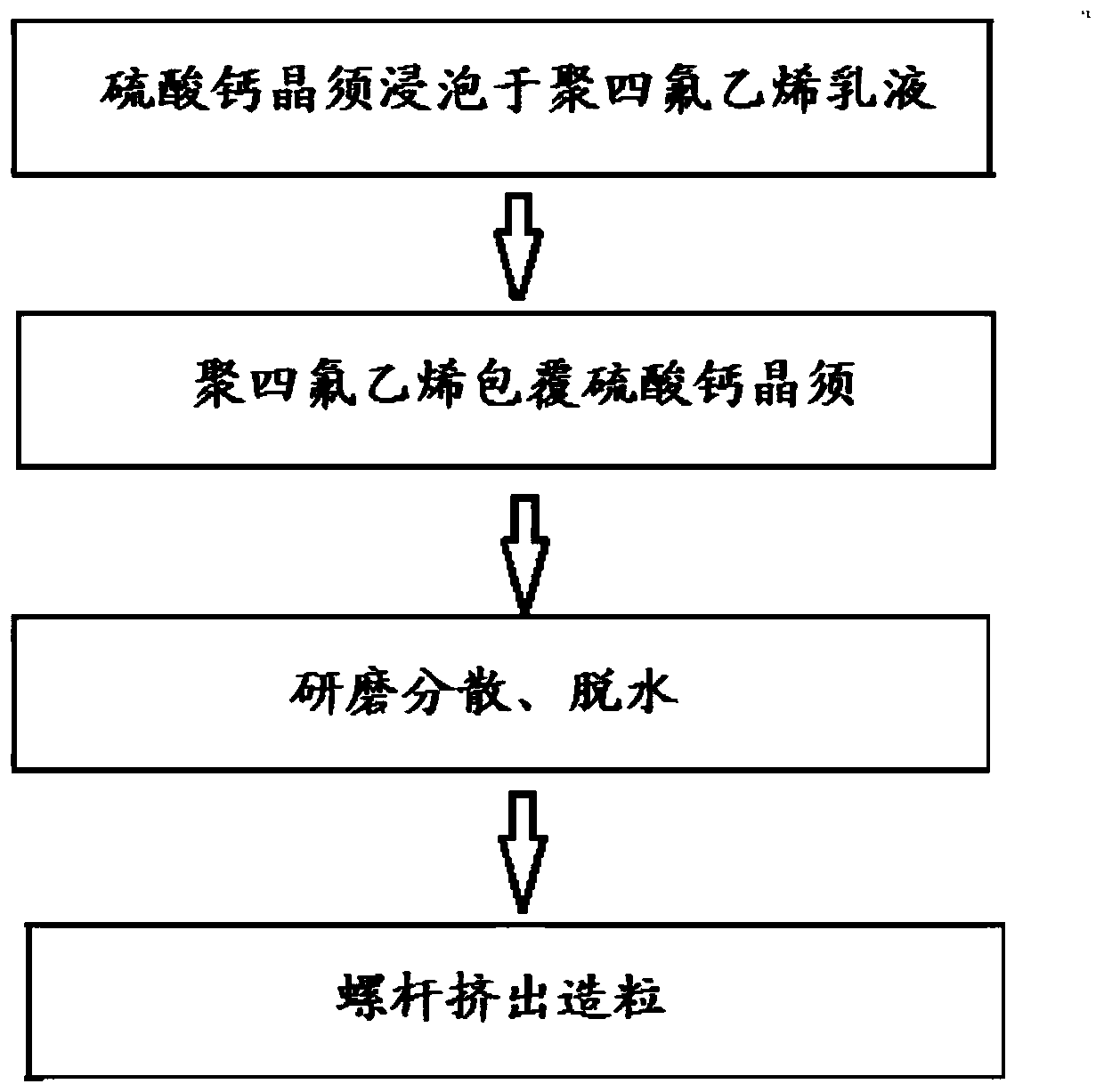

[0036] (1) Disperse calcium sulfate whiskers with a diameter of 1-10 μm and an aspect ratio of 10-20 in an excess mass concentration of 3% polytetrafluoroethylene emulsion and soak for 1 hour, and then use the ALX-2000W centrifugal filter tester at high speed Centrifugal filtration to remove excess emulsion, the centrifugal speed is controlled at 10000rpm, and the centrifugation time is 3min; the obtained calcium sulfate whiskers coated with polytetrafluoroethylene are sent to a high-speed disperser for heating and stirring to disperse, and the high-speed disperser adopts 800rpm The rotating speed makes the material fully disperse in the suspension state, and heats to 100°C to dry and solidify the coated PTFE emulsion to obtain dry calcium sulfate whiskers coated with PTFE;

[0037] (2) Send the calcium sulfate whisker coated with PTFE into NORVA high-energy NGS50 airflow grinder, and the air flow of the airflow grinder is controlled at 500m 3 / h, speed 2000r / min. The heating...

Embodiment 2

[0040] (1) Disperse calcium sulfate whiskers with a diameter of 1-10 μm and an aspect ratio of 10-20 in an excess mass concentration of 3% polytetrafluoroethylene emulsion and soak for 1 hour, and then use the ALX-2000W centrifugal filter tester at high speed Centrifugal filtration to remove excess emulsion, the centrifugal speed is controlled at 10000rpm, and the centrifugation time is 3min; the obtained calcium sulfate whiskers coated with polytetrafluoroethylene are sent to a high-speed disperser for heating and stirring to disperse, and the high-speed disperser adopts 800rpm The rotating speed makes the material fully disperse in the suspension state, and heats to 100°C to dry and solidify the coated PTFE emulsion to obtain dry calcium sulfate whiskers coated with PTFE;

[0041] (2) Send the calcium sulfate whisker coated with PTFE into NORVA high-energy NGS50 airflow grinder, and the air flow of the airflow grinder is controlled at 500m 3 / h, speed 2000r / min. The heating...

Embodiment 3

[0044] (1) Disperse calcium sulfate whiskers with a diameter of 1-10 μm and an aspect ratio of 10-20 in an excess mass concentration of 3% polytetrafluoroethylene emulsion and soak for 1 hour, and then use the ALX-2000W centrifugal filter tester at high speed Centrifugal filtration to remove excess emulsion, the centrifugal speed is controlled at 10000rpm, and the centrifugation time is 3min; the obtained calcium sulfate whiskers coated with polytetrafluoroethylene are sent to a high-speed disperser for heating and stirring to disperse, and the high-speed disperser adopts 800rpm The rotating speed makes the material fully disperse in the suspension state, and heats to 100°C to dry and solidify the coated PTFE emulsion to obtain dry calcium sulfate whiskers coated with PTFE;

[0045] (2) Send the calcium sulfate whisker coated with PTFE into NORVA high-energy NGS50 airflow grinder, and the air flow of the airflow grinder is controlled at 500m 3 / h, speed 2000r / min. The heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com