A kind of whisker reinforced hydrophobic nylon 66 composite material and preparation method

A composite material and hydrophobic technology, which is applied in the field of nylon engineering plastics, can solve the problems that affect the dimensional stability and strength of products, nylon 66 is easy to absorb water, and deform, and achieve the value of extensive large-scale promotion of production, excellent water and oil repellency, The effect of simple preparation process

Active Publication Date: 2022-06-03

浙江祥丰新材料科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

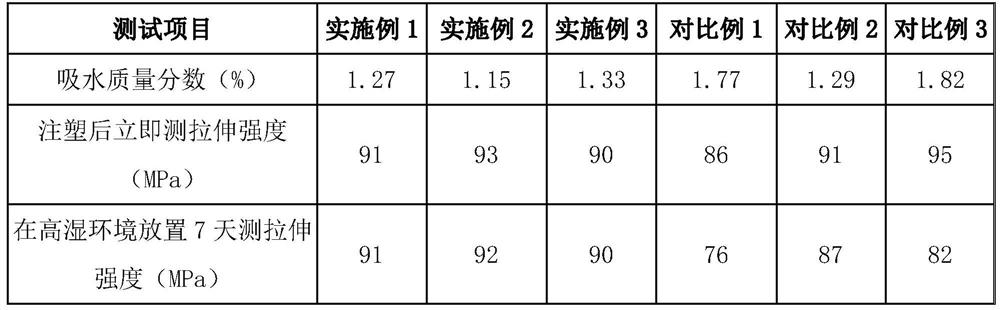

[0006] Aiming at the current problem that nylon 66 is easy to absorb water and causes swelling and deformation to affect the dimensional stability and strength of the product, the present invention proposes a whisker-reinforced hydrophobic nylon 66 composite material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Login to View More

Abstract

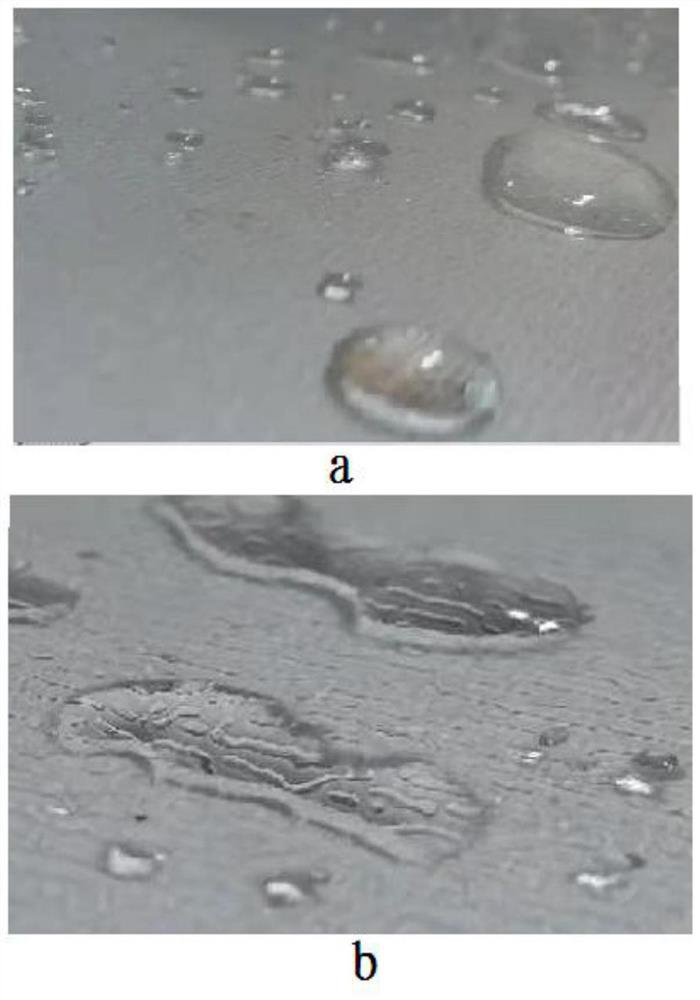

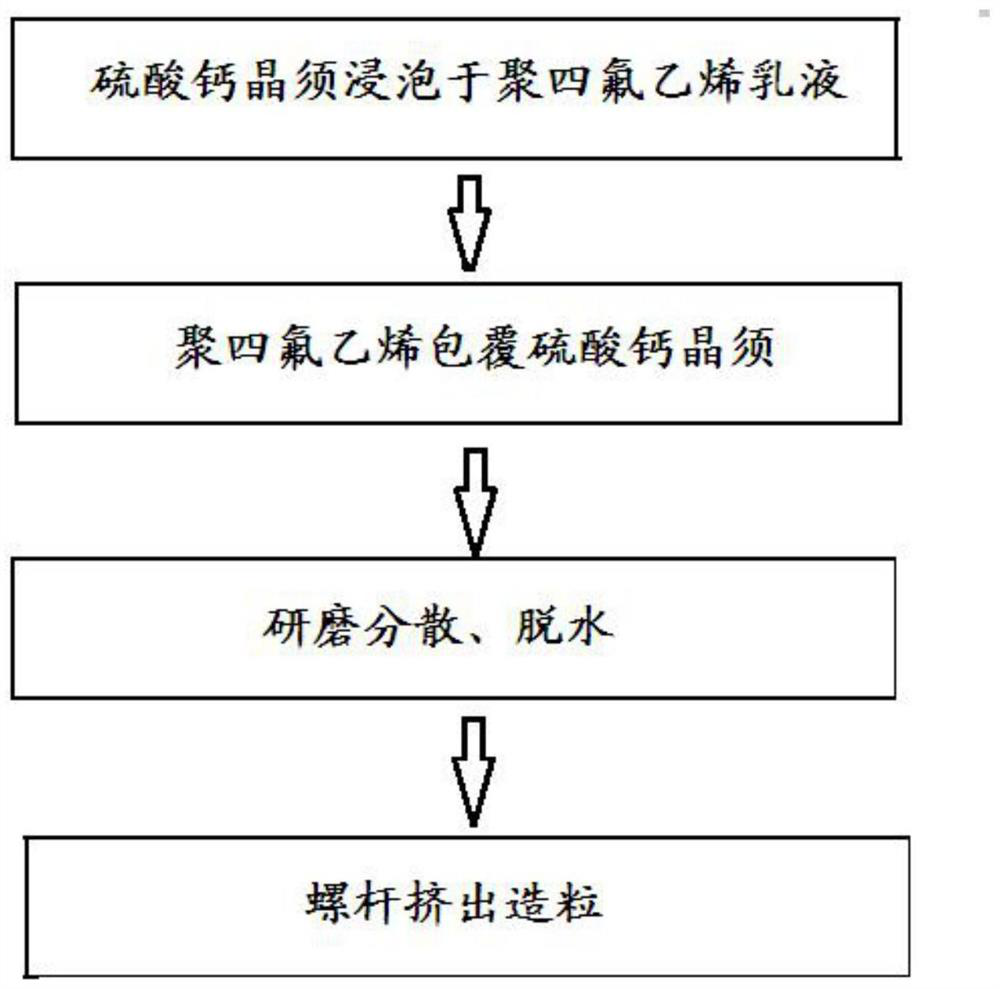

The invention belongs to the field of nylon engineering plastics, in particular to a whisker-reinforced hydrophobic nylon 66 composite material and a preparation method. By firmly attaching hydrophobic polytetrafluoroethylene to the surface of calcium sulfate whiskers and dispersing it as a filler in nylon 66, the hydrophobicity of polytetrafluoroethylene endows nylon 66 with a good hydrophobic effect, and at the same time, polytetrafluoroethylene is firm Coated on the surface of calcium sulfate whiskers, dispersed by the network of calcium sulfate whisker fibers, there will be no problem of PTFE segregation, and calcium sulfate whiskers can effectively increase the strength of nylon 66. Further, the present invention adds hydrophobic additives to the nylon 66 system. This type of material has excellent water and oil repellency properties, and it is easy for nylon 66 to form hydrogen bonds after being used in nylon 66, so that the carbonyl and carbonyl groups in nylon 66 occupied in advance Amino groups, which block the entry of water molecules.

Description

Whisker-reinforced hydrophobic nylon 66 composite material and preparation method thereof technical field The invention belongs to the nylon engineering plastics field, particularly relate to a kind of whisker reinforced hydrophobic nylon 66 composite material and preparation method. Background technique Nylon 66 (PA66) is a kind of polyamide polymer, which was successfully developed by DuPont in 1938. Polycondensation with hexamethylene diamine to form a polymer, PA66 has high crystallinity, hydrogen bonds can be formed between molecular chains, and the molecular force is strong. Therefore, PA66 has the characteristics of good tensile strength, hardness and resistance to organic solvents, and is widely used in industry. Nylon 66 (PA66) has been widely used in structural parts of automobiles, electrical appliances, general machinery and other products, it has good strength and resistance Impact performance is one of the most widely used engineering plastics. In r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L77/06C08L51/06C08L83/06C08L83/04C08K13/06C08K9/10C08K7/08C08K3/30C08K3/34C08K7/26C08J5/06

CPCC08J5/06C08K2003/3045C08J2377/06C08J2451/06C08J2483/06C08J2483/04C08K13/06C08K9/10C08K7/08C08K3/346C08K3/34C08K7/26C08K2201/011

Inventor 朱世岳陈亦欣陈湘谢亮

Owner 浙江祥丰新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com