Silicone-modified styrene-butadiene latex and preparation method thereof

A technology of styrene-butadiene latex and silicone, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of large amount of emulsifier, easy water absorption, easy adhesion, etc., and achieve good fluidity, high strength, and good alkali resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

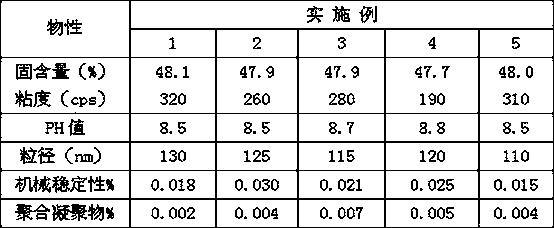

Examples

Embodiment 1

[0043] The 300L polymerization kettle is first evacuated, and the vacuum degree reaches -0.1MPa. According to the input of soft water 76KG, the pre-emulsion 12KG, 5.0KG butadiene, 5.0KG styrene, heat up, when the temperature reaches 80°C, add 20%-30% initiator, react for about 1 hour, then add the following components dropwise at the same time:

[0044] pre-emulsion : 35KG

[0045] Butadiene: 45KG

[0046] Styrene: 45KG

[0047] Initiator: 0.3KG

[0048] Dodecyl mercaptan: 0.3KG.

[0049] The dropping time is 2.5 hours, and the temperature is controlled at about 85° C. during the dropping. Raise the temperature to 95°C and keep it warm for 3 hours. When the conversion rate reaches above 98%, perform degassing treatment to remove unreacted monomers, add lye to adjust the pH value to 7~9, and cool down to below 40°C Out of the packaging, a silicone-modified styrene-butadiene latex with excellent performance is prepared, with a solid content of 48.1%, a viscosity of 320 ...

Embodiment 2

[0051] The 300L polymerization kettle is first evacuated, and the vacuum degree reaches -0.1MPa. According to the input of soft water 71KG, the pre-emulsion 14KG, 8.0KG butadiene, 8.0KG styrene, heat up, when the temperature reaches 80°C, add 20%-30% initiator, react for about 1 hour, then add the following components dropwise at the same time:

[0052] pre-emulsion : 40KG

[0053] Butadiene: 47KG

[0054] Styrene: 37KG

[0055] Initiator: 0.3KG

[0056] Dodecyl mercaptan: 0.3KG.

[0057] The dropping time is 3 hours, and the temperature is controlled at about 85° C. during the dropping. Reaction at 95°C for 2 hours, when the conversion rate reaches above 98%, perform degassing treatment to remove unreacted monomers, add lye to adjust the pH value to between 7 and 9, cool down and discharge the material for packaging, and the product is obtained A silicone-modified styrene-butadiene latex with excellent performance, with a solid content of 47.9%, a viscosity of 260 cp...

Embodiment 3

[0059]The 300L polymerization kettle is first evacuated, and the vacuum degree reaches -0.1MPa. According to the input of soft water 73KG, the pre-emulsion 15KG, 12KG butadiene, 4KG styrene, heat up, when the temperature reaches 80°C, add 20%-30% initiator, react for about 1 hour, then add the following components dropwise at the same time:

[0060] pre-emulsion : 42KG

[0061] Butadiene: 48KG

[0062] Styrene: 36KG

[0063] Initiator: 0.4KG

[0064] Dodecyl Mercaptan: 0.4KG.

[0065] The dropping time was 3 hours, and the temperature was controlled at about 88° C. during the dropping. The temperature was raised to 95°C for 3 hours, and when the conversion rate reached over 98%, degassing treatment was carried out to remove unreacted monomers, and lye was added to adjust the pH value to between 7 and 9, and the temperature was lowered for packaging. That is to say, a silicone-modified styrene-butadiene latex with excellent performance was obtained, with a solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com