Modified collagen fibers as well as preparation method and application thereof

A collagen fiber and modification technology, which is applied in the field of modified collagen fiber and its preparation to achieve the effects of prolonging normal use time, improving mechanical properties and delaying oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

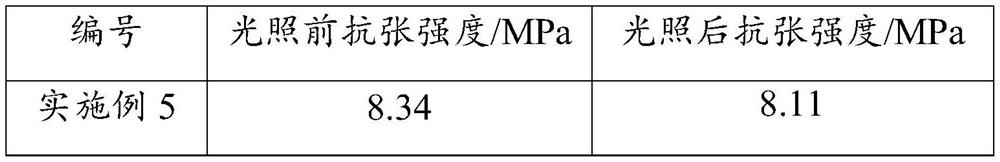

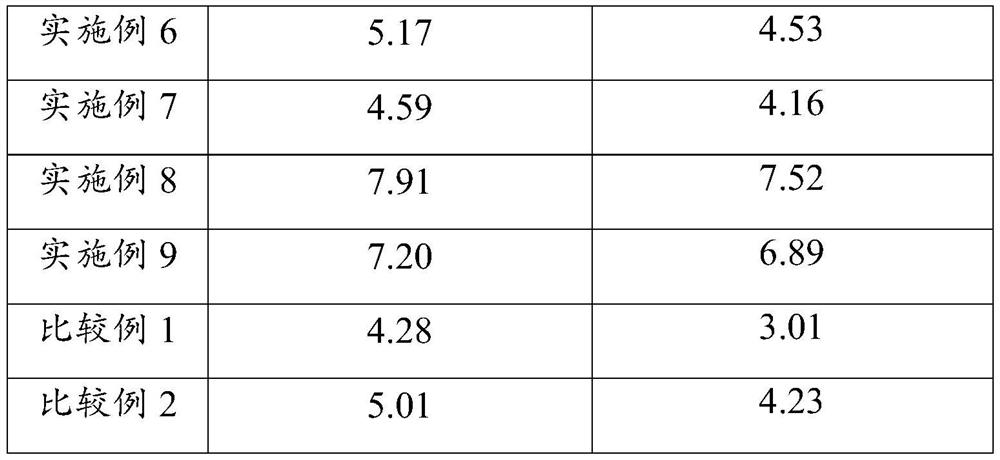

Examples

Embodiment 1

[0064] This embodiment provides a method for preparing modified collagen fibers, including the following steps:

[0065] (1) Get 1kg red bayberry tannin and add 5kg deionized water, stir until red bayberry tannin is all dissolved, obtain the aqueous solution of red bayberry tannin, stand-by;

[0066] Take 3kg of collagen fibers and place them in a container, add 150kg of deionized water, and stir to disperse the collagen fibers in the water evenly to obtain an aqueous dispersion of collagen fibers; the mass ratio of tannin to collagen fibers is 1:3.

[0067] (2) In the aqueous dispersion of collagen fibers prepared in step (1), add the aqueous solution of bayberry tannin prepared in step (1) to obtain a mixed material; then use 0.1mol / L of sodium bicarbonate The aqueous solution adjusts the pH of the mixed material to 6.5-7 and keeps it stable. After mechanical stirring for 5 hours, filter through a Buchner funnel, wash the solid material with absolute ethanol, and repeat 3 ti...

Embodiment 2

[0069] The present embodiment refers to the preparation method of Example 1, the difference is only in:

[0070] In step (1), get 3kg red bayberry tannin and add 15kg deionized water, stir until red bayberry tannin is all dissolved, obtain the aqueous solution of red bayberry tannin, stand-by;

[0071] Take 3kg of collagen fibers and place them in a container, add 150kg of deionized water, and stir to disperse the collagen fibers evenly in the water to obtain an aqueous dispersion of collagen fibers; the mass ratio of bayberry tannin to collagen fibers is 1:1.

Embodiment 3

[0073] The present embodiment refers to the preparation method of Example 1, the difference is only in:

[0074] In step (1), get 0.3kg red bayberry tannin and add 1.5kg deionized water, stir until red bayberry tannin is all dissolved, obtain the aqueous solution of red bayberry tannin, stand-by;

[0075] Take 3 kg of collagen fibers and place them in a container, add 150 kg of deionized water, stir to disperse the collagen fibers evenly in the water, and obtain an aqueous dispersion of collagen fibers; the mass ratio of bayberry tannin to collagen fibers is 1:10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com