Self-emulsifying wet rubbing resistant leather top layer coating agent and preparation method thereof

A self-emulsifying, finishing agent technology, used in fiber processing, textiles and papermaking, etc., can solve the problems of low overall performance, unstable wet rub resistance, hindering the water vapor permeability of leather, and achieve a soft hand feel and excellent rub resistance. The effect of wet performance and excellent water vapor permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

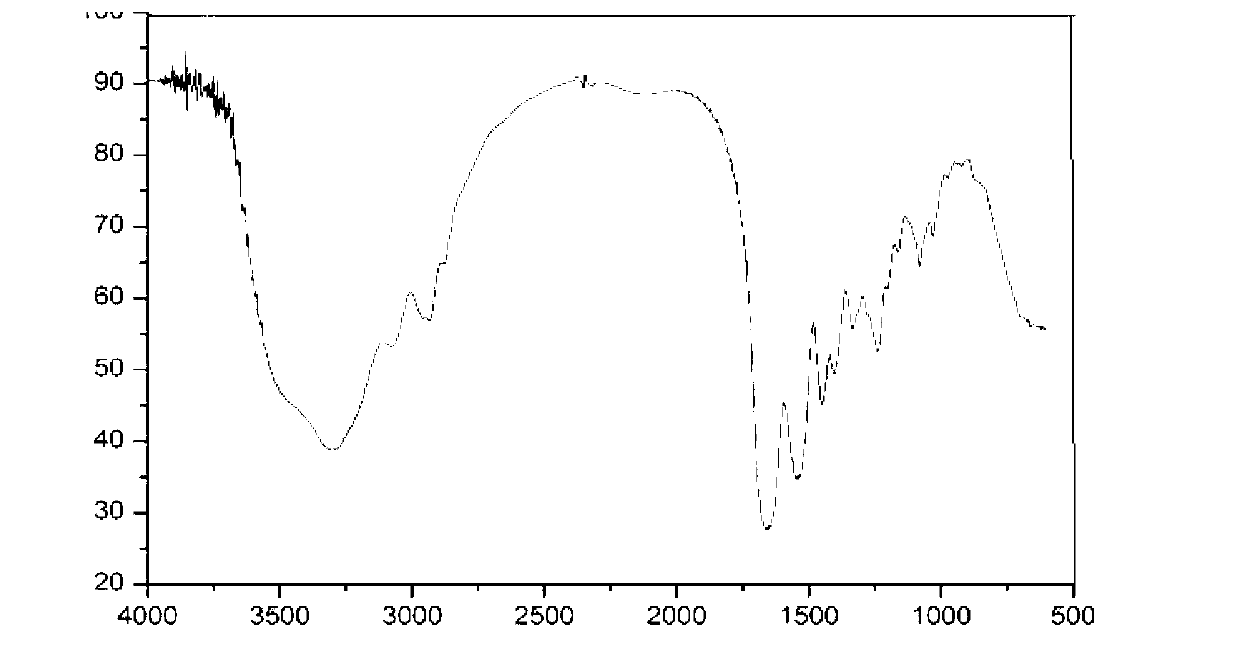

[0034] Add 12 grams of gelatin (accounting for 11.76% of the total mass) and 85 grams of deionized water into a three-neck reaction flask equipped with a thermometer socket, a sampling port, and a condenser socket, stir and heat to 65 °C, and after the gelatin is completely dissolved, add 0.5 mL, 3 mol / liter of sodium hydroxide, adjust the reaction pH to be 9.0, add 5.0g sodium lauryl sulfate, sodium dodecylbenzenesulfonate and sorbitol mixed surfactant (wherein sodium lauryl sulfate 55% (w / w), sodium dodecylbenzenesulfonate 20% (w / w), sorbitol 25% (w / w)) as an emulsifier (4.90% of the total mass), continue After stirring until the emulsifier is completely dissolved, add epoxy polysiloxane (Mw=1000) continuously or in batches, the reaction starts, and the content of primary amino groups in the system does not change after 24 hours of reaction, so stop stirring and heating.

[0035] The dissolution rate of the product in deionized water is 43%. The dissolution rate of the prod...

Embodiment 2

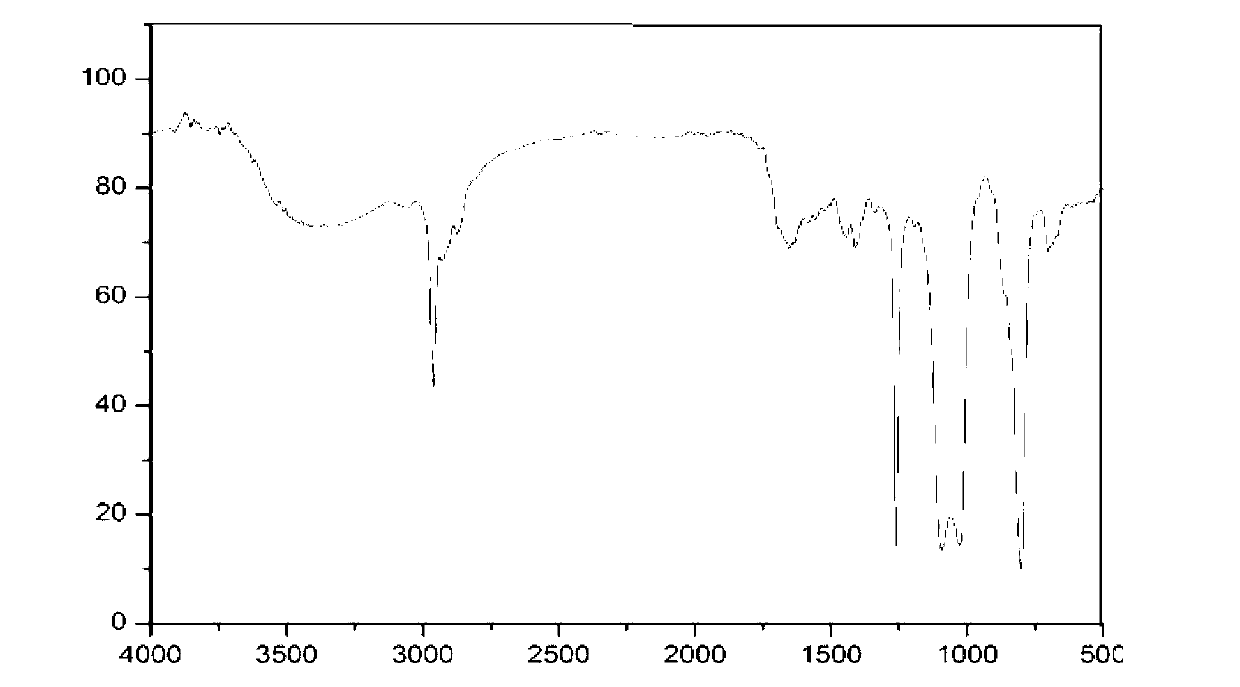

[0045] Add 12 grams of gelatin (accounting for 11.76% of the total mass) and 85 grams of deionized water into a three-neck reaction flask equipped with a thermometer socket, a sampling port, and a condenser socket, stir and heat to 65 °C, and after the gelatin is completely dissolved, add 0.5 mL, 3 mol / liter of sodium hydroxide, adjust the reaction pH to be 9.0, add 5.0g sodium dodecyl sulfate, sodium dodecylbenzenesulfonate and sorbitol mixed surfactant (wherein dodecylsulfonic acid Sodium is 55% (w / w), sodium dodecylbenzenesulfonate is 20% (w / w), sorbitol is 25% (w / w)) as an emulsifier (4.90% of the total mass), Continue to stir until the emulsifier is completely dissolved, then add epoxy polysiloxane (Mw=1000) continuously or in batches, the reaction starts, and the content of primary amino groups in the system does not change after 24 hours of reaction, so stop stirring and heating.

[0046] Take 10.0 grams of prepared modified gelatin, add 10 mL of a mixed solvent of abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

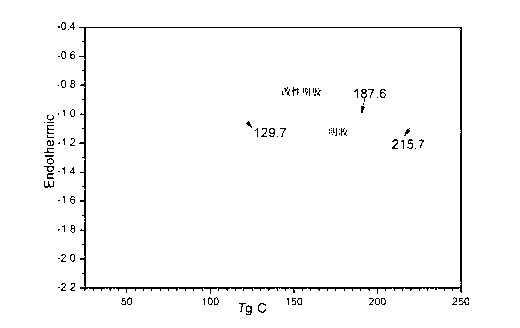

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com