Method for improving hygienic performance of figured-island superfine fiber synthetic leather

A technology of ultra-fine fiber and hygienic performance, applied in the field of synthetic leather, can solve the problems of difficult control, poor effect, damage to the appearance and coating performance of synthetic leather, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

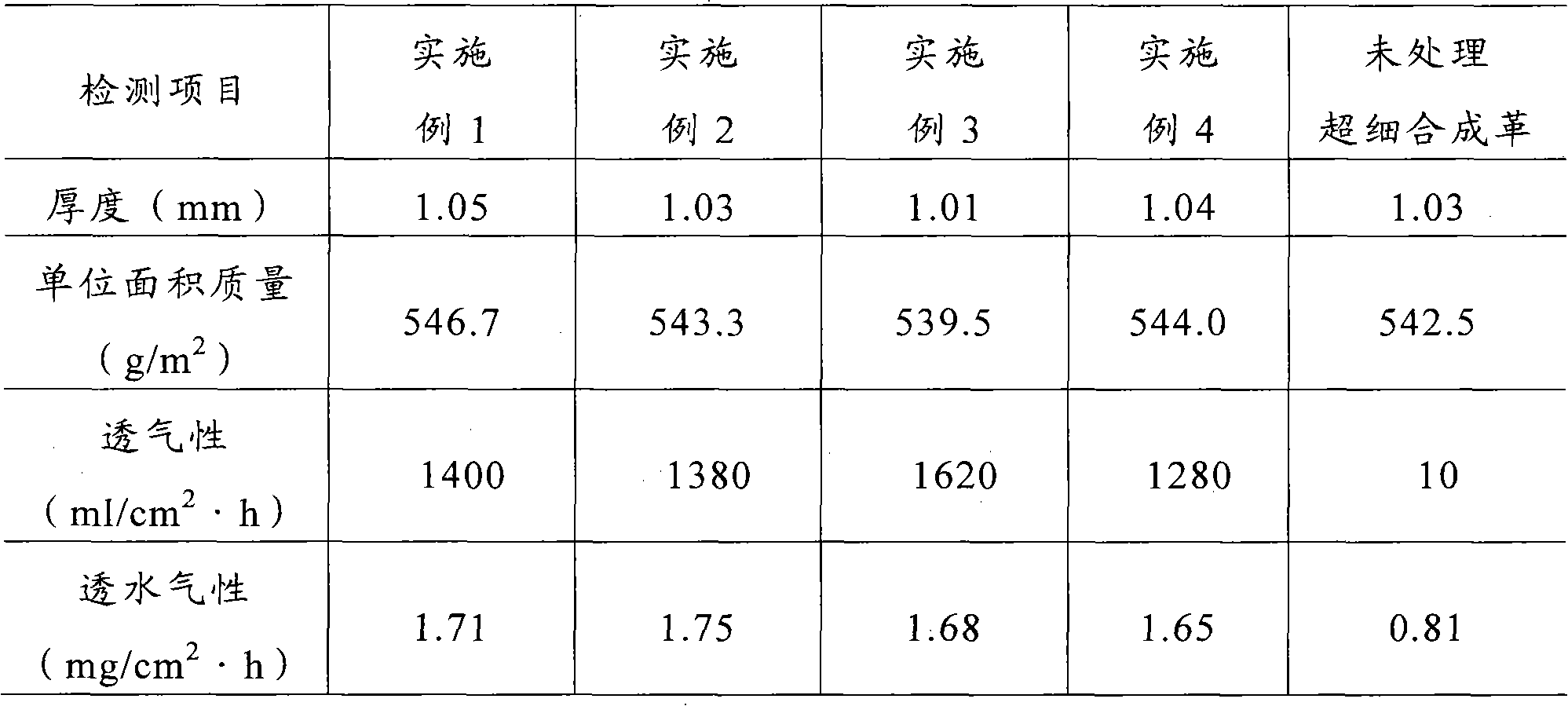

Embodiment 1

[0059] Base fabric modification treatment process

[0060] Take 3 square meters of Dingdao microfiber base cloth and weigh it;

[0061] Put the Dingshima superfine fiber base cloth in the water kneading machine, add hot water at a temperature of 60°C, the amount of hot water added is 320% of the weight of the base cloth, and then add 6.5% of the weight of the base cloth to the water kneading machine Polyurethane grafted modified collagen, turn on the water kneading machine and rotate for 35 minutes; add glutaraldehyde resin cross-linking agent accounting for 1.1% of the weight of the base cloth into the water kneading machine, turn on the water kneading machine and rotate for 35 minutes, then knead the water The liquid in the machine is discharged;

[0062] The first washing process:

[0063] Add hot water at 55°C to the water kneading machine, the amount of hot water added accounts for 300% of the weight of the superfine fiber synthetic leather base cloth, turn on the water...

Embodiment 2

[0072] Base fabric modification treatment process

[0073] Take 3 square meters of Dingdao microfiber base cloth and weigh it;

[0074] Put the Dingshima superfine fiber base cloth in the water kneading machine, add hot water at a temperature of 60°C, the amount of hot water added is 320% of the weight of the base cloth, and then add 6.5% of the weight of the base cloth to the water kneading machine Acrylic acid grafted modified collagen, turn on the water kneading machine and rotate for 35 minutes; The liquid in the machine is discharged;

[0075] The first washing process:

[0076] Add hot water at 55°C to the water kneading machine, the amount of hot water added accounts for 300% of the weight of the superfine fiber synthetic leather base cloth, turn on the water kneading machine and rotate for 6.5 minutes, and discharge the liquid in the water kneading machine;

[0077] Filling hydrophilic material process:

[0078] Add hot water at 55°C to the water kneading machine, th...

Embodiment 3

[0085] Base fabric modification treatment process

[0086] Take 3 square meters of Dingdao microfiber base cloth and weigh it;

[0087] Put the Dingshima superfine fiber base cloth in the water kneading machine, add hot water at a temperature of 60°C, the amount of hot water added is 320% of the weight of the base cloth, and then add 6.5% of the weight of the base cloth to the water kneading machine Graft modified collagen with urea-formaldehyde resin, turn on the water kneading machine and rotate for 35 minutes; add an acrylic medium modified glutaraldehyde crosslinking agent accounting for 1.1% of the base cloth weight in the water kneading machine, turn on the water kneading machine and rotate for 35 minutes, Then drain the liquid in the water kneader;

[0088] The first washing process:

[0089] Add hot water at 60°C to the water kneading machine, the amount of hot water added accounts for 350% of the weight of the superfine fiber synthetic leather base cloth, turn on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com