Preparation method of dentritic waterborne polyurethane

A water-based polyurethane and dendritic technology, which is applied in the field of water-based polyurethane preparation, can solve the problems of polluting environmental materials and unsafety, and achieve the effects of structural safety and environmental protection, safe use, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

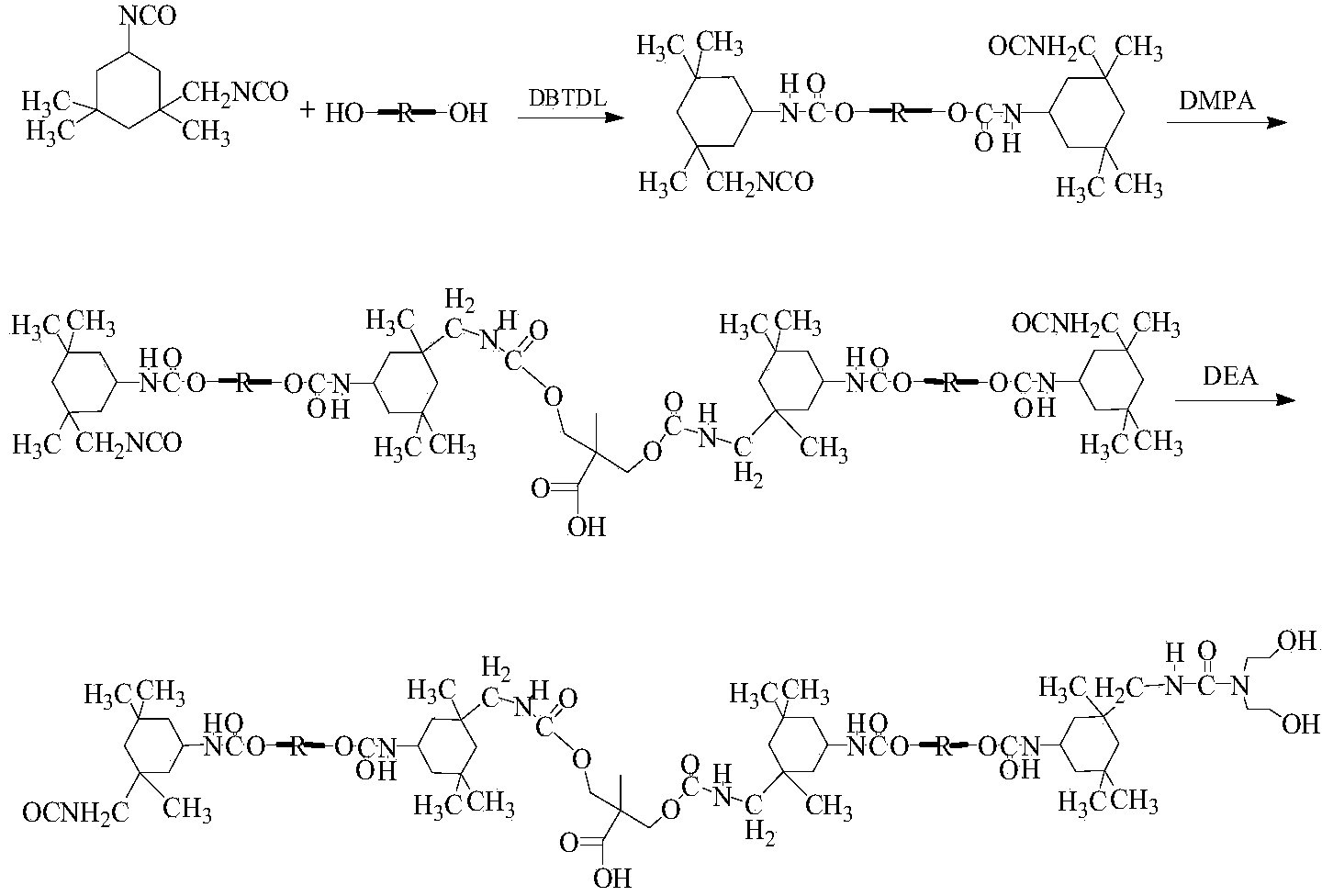

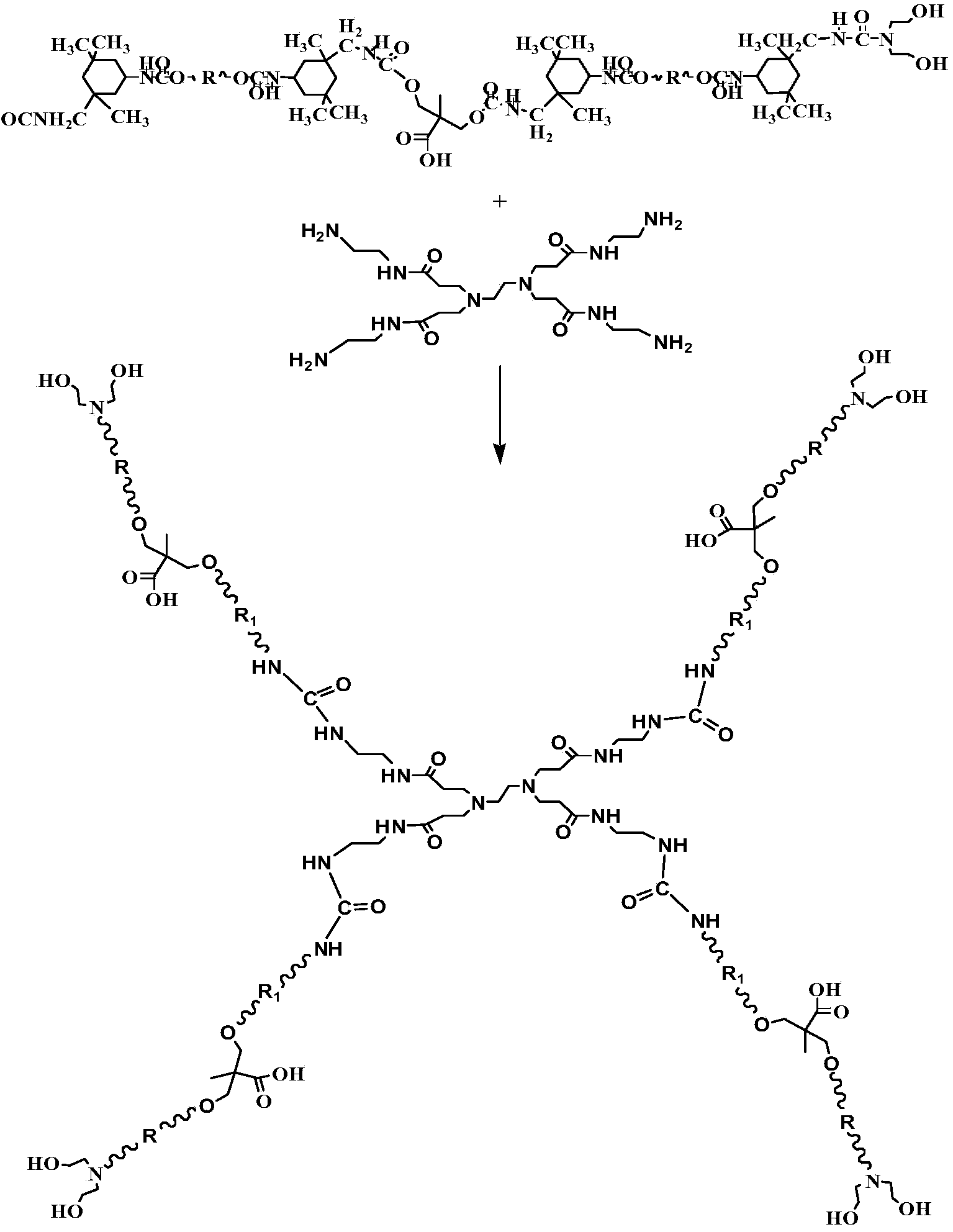

[0025] see figure 1 with figure 2 , add 17.8g of isophorone diisocyanate (IPDI) and polyol (polyol is a mixture of 20.0g polycarbonate diol and 9.0g castor oil) into the four-port reaction kettle, mix well and add two drops of catalyst two Butyl tin dilaurate (DBTDL), the quality of two drops of dibutyl tin dilaurate is 0.005% of the total mass of isophorone diisocyanate and polyol, then stir and react at 75°C for 90 minutes and then add 4% (Based on the total mass of IPDI and polyols) Dimethylolpropionic acid (DMPA) is used as a hydrophilic chain extender, the temperature is lowered to 75 ° C for about 2 hours, and then the temperature is lowered to 0-20 ° C and then added diethanolamine (DEA ) 2.1g for single-end blocking, after 30 minutes of reaction, add 2.2g of 1G PAMAM (first-generation polyamide-amine) for 30 minutes, continue to stir and heat up to 60°C, and add 1.90g of triethylamine for neutralization reaction for 30 minutes, and finally put The reaction product i...

Embodiment 2

[0027] In a four-port reaction kettle, add 14.0g of toluene diisocyanate (TDI) and polyol (20.0g of polycarbonate diol and 10.0g of castor oil), mix well and add three drops of catalyst bismuth carboxylate, three drops of bismuth carboxylate The mass is 0.008% of the total mass of toluene diisocyanate and polyol, stirred and reacted at 80°C for 80 minutes, and then added 5% (based on the total mass of TDI and polyol) of dimethylol butyric acid (DMBA) as a pro- Water chain extender, the temperature drops to 75°C and reacts for about 2 hours, then cools down to 0-20°C and then adds 2.5g of diethanolamine (DEA) for single-end blocking. After reacting for 30min, add 2.2g of 1G PAMAM to react for 30min, continue to stir and heat up to 40°C, add 2.5g of potassium hydroxide for neutralization reaction for 30 minutes, and finally disperse the reaction product into deionized water under the forced force of the disperser to obtain a dendritic water-based polyurethane emulsion; wherein, t...

Embodiment 3

[0029] In a four-port reactor, add 20.0g of diphenylmethane-4,4'-diisocyanate (MDI) and polyol (20.0g of polycarbonate diol and 9.5g of castor oil), mix well and add two drops of catalyst Dibutyltin dilaurate (DBTDL), the mass of two drops of dibutyltin dilaurate is 0.006% of the total mass of diphenylmethane-4,4'-diisocyanate and polyol, and the reaction is stirred at 85°C After 60 minutes, the viscosity of the reaction system increased, and acetone was added to adjust the viscosity to facilitate stirring, and then 6% (based on the total mass of MDI and polyol) of dimethylolpropionic acid (DMPA) was added as a hydrophilic chain extender. Lower the temperature to 75°C for about 2 hours, then lower the temperature to 0-20°C, add 2.0g of diethanolamine (DEA) for single-end blocking, add 2.22g of 1G PAMAM to react for 30min after reacting for 30min, continue to stir and raise the temperature to 60°C, add three Ethylamine 2.22g was neutralized for 30 minutes, and finally the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com