Preparation method of super-hydrophobic crosslinked polysiloxane-polysilsesquioxane nanosphere hybrid material

A technology of cross-linked polysiloxane and polysilsesquioxane, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor durability, poor softness, and hard hand feeling of superhydrophobic fabrics, and achieve the goal of improving the hand feel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

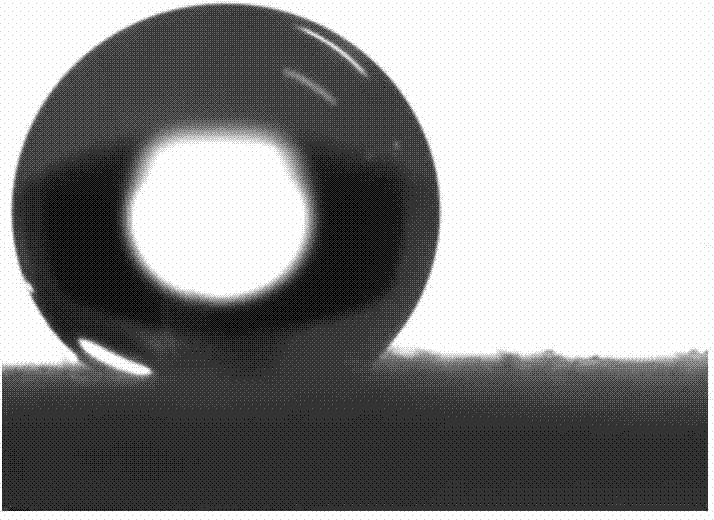

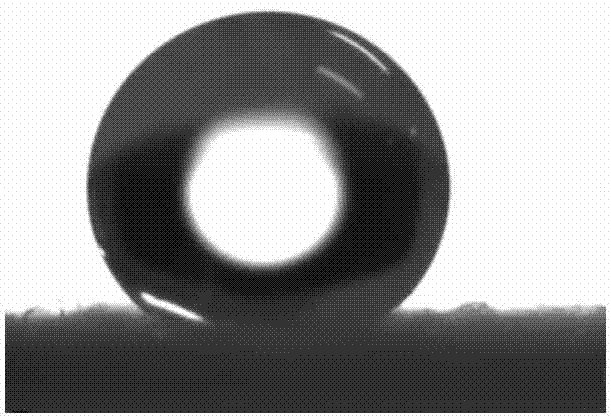

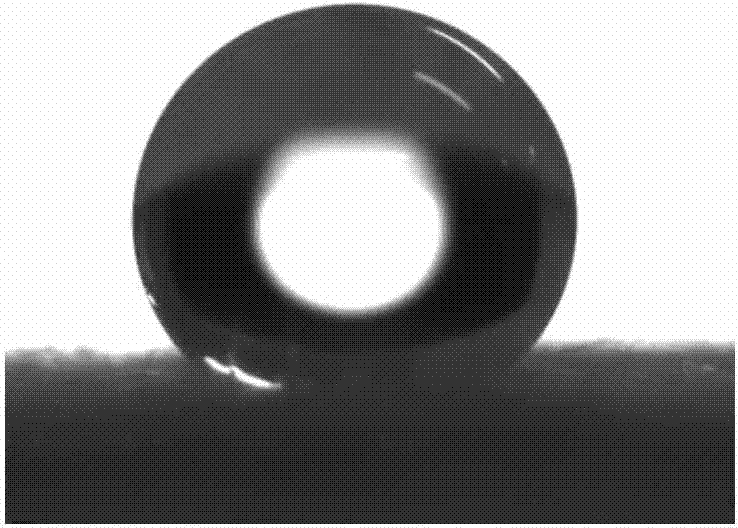

Image

Examples

Embodiment 1

[0036] (1) Add 60g structure as shown in formula (II) in the three-neck bottle that device has thermometer, reflux condenser and electric stirrer, R=OH, viscosity is 950mPa·s, epoxy value is 0.04mmol / g, The side Ep-PDMS-Vi and 10.2g structure with ethylene value of 0.15mmol / g are shown in formula (Ⅲ) (R′=CH 3 ) side hydrogen-containing silicone oil (viscosity is 140mPa s, Si-H content is 0.08%), the molar ratio of the C=C double bond in the side Ep-PDMS-Vi to the Si-H bond in the side hydrogen-containing silicone oil is 1.1: 1. Stir evenly and heat to 85°C, then add 2.1 mg of chloroplatinic acid (catalyst) and keep it warm for 4 hours to obtain a colorless and transparent viscous liquid, which is a cross-linked epoxy side group and reactive Si-OH group with low surface energy. Dipolysiloxane (obtaining 69.5g), the structure is shown in formula (I), R=OH, R'=CH 3 , the viscosity at room temperature is 1150mPa·s, and the epoxy value is 0.033mmol / g;

[0037] (2) Add 500 g of di...

Embodiment 2

[0039] (1) Add 60g structure as shown in formula (II) in the three-neck bottle that device has thermometer, reflux condenser and electric stirrer, R=OH, viscosity is 768mPa·s, epoxy value is 0.06mmol / g, The structure of the side Ep-PDMS-Vi and 4.4g with an ethylene value of 0.08mmol / g is shown in formula (Ⅲ) (R'=CH 2 CH 2 CF 3 ) side hydrogen-containing silicone oil (viscosity is 280mPa s, Si-H content is 0.1%), the molar ratio of the C=C double bond in the side Ep-PDMS-Vi to the Si-H bond in the side hydrogen-containing silicone oil is 1.1: 1. Stir evenly and heat to 85°C, then add 2.0 mg of chloroplatinic acid (catalyst) and keep it warm for 4 hours to obtain a colorless and transparent viscous liquid, which is a cross-linked epoxy side group and reactive Si-OH group with low surface energy. Dipolysiloxane (obtaining 64.1g), the structure is shown in formula (I), R=OH, R'=CH 2 CH 2 CF 3 , the viscosity at room temperature is 1530mPa·s, and the epoxy value is 0.055mmol / g...

Embodiment 3

[0043] (1) Add 60g of structure as shown in formula (II) in the three-neck bottle that device has thermometer, reflux condenser and electric stirrer, R=OCH 2 CH 3 , the viscosity is 1070mPa·s, the epoxy value is 0.04mmol / g, the ethylene value is 0.10mmol / g side Ep-PDMS-Vi and 5.5g side hydrogen-containing silicone oil (R′= CH 3 , the viscosity is 125mPa s, the Si-H content is 0.1%), the molar ratio of the C=C double bond in the side Ep-PDMS-Vi to the Si-H bond in the side hydrogen-containing silicone oil is 1.1:1, stir evenly and heat to 85°C, then add 2.0 mg of chloroplatinic acid (catalyst) and keep it warm for 4 hours to obtain a colorless and transparent viscous liquid, that is, a low surface energy cross-linked polysiloxane containing epoxy side groups and reactive Si-OH groups ( Obtain 65.1g), structure as shown in formula (I), the viscosity at room temperature is 1700mPa s, epoxy value is 0.035mmol / g;

[0044] (2) add 500g distilled water, 1.60gKOH, and 4.0g mixed em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com