Method of preparing intelligent energy-saving vanadium dioxide by hydrothermal method

A vanadium dioxide, hydrothermal technology, applied in vanadium oxide, chemical industry, climate sustainability and other directions, can solve the problems of difficult to obtain VO2 pure phase, difficult to control vanadium valence state, difficult to large-scale production and so on , to achieve the effect of superior intelligent energy-saving cycle performance, easy to scale up mass production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

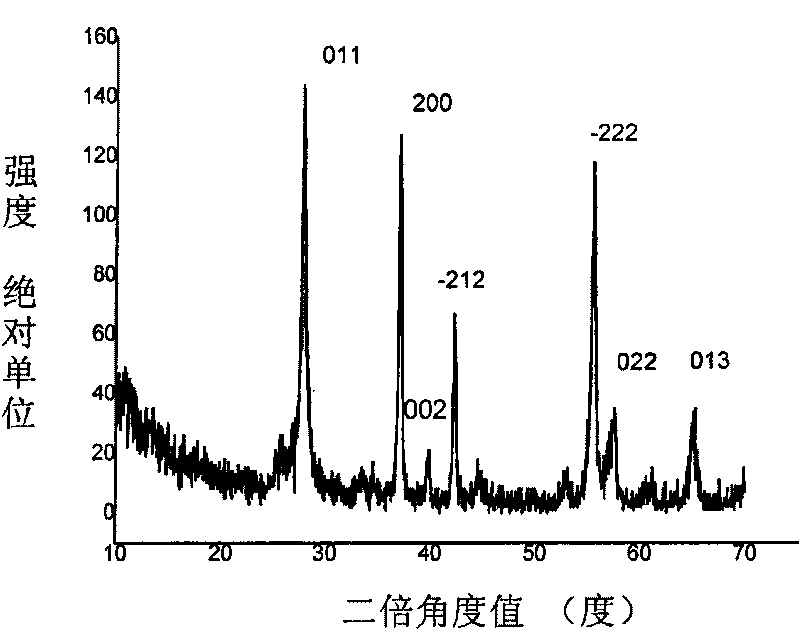

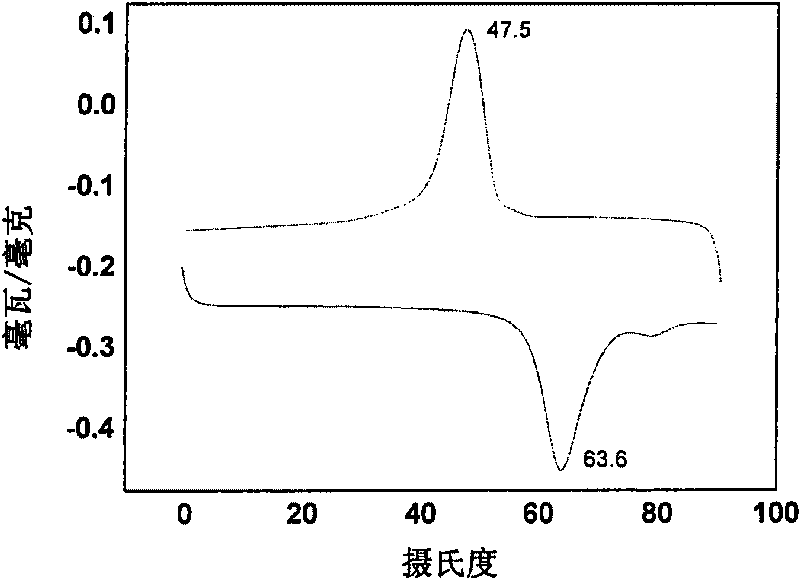

[0031] Monoclinic VO 2 (VO 2 (M)) Realization of uniform ultra-long nanowires: add 2mmol ammonium metavanadate (NH 4 VO 3 ), and add 45ml of water, and then add 1ml of 1mol / L ammonia water to completely dissolve the ammonium metavanadate in the alkaline aqueous solution, then add 1ml of hydrazine hydrate, and stir for 10min. After sealing the hydrothermal autoclave, place it in an oven at 200° C. for 30 h. After natural cooling, the obtained product was washed with deionized water and absolute ethanol to remove possible impurities. Such as figure 1 As shown, all X-ray powder diffraction peaks can be indexed as VO 2 (M) powder, and no other impurity peaks occur, so what is synthesized in Example 1 is high-purity VO 2 (M) Powder material. figure 2 According to the test results of the intelligent energy-saving performance of the product obtained according to the embodiment of the present invention, the test chart is the actual measurement curve of 20 cycles. It can be see...

Embodiment 2

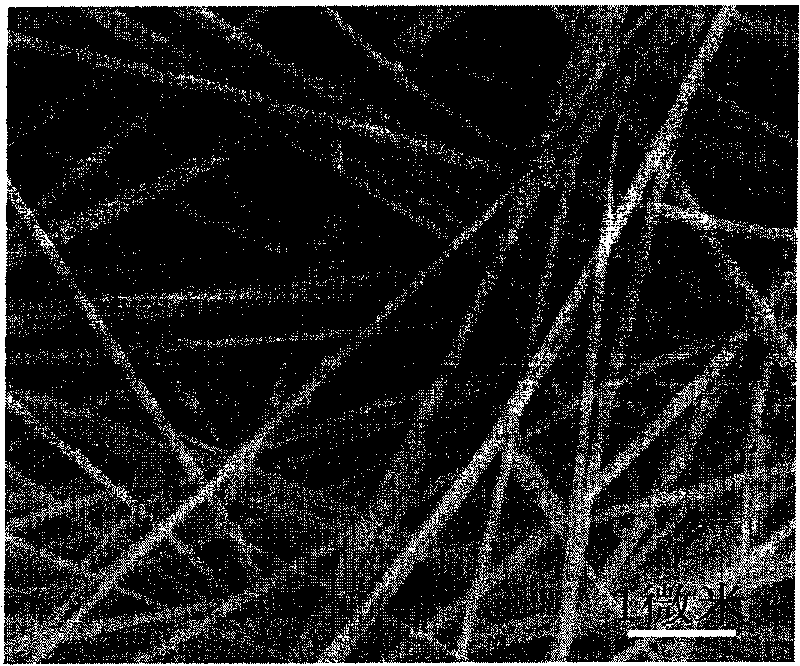

[0033] Nano-sized monoclinic VO 2 (VO 2 (M)) The realization of the smooth nanobelt of powder material: add 2mmol acetylacetonate vanadyl complex in 50ml polytetrafluoroethylene liner, and add 45ml water, add the hydrochloric acid of 0.5ml 1mol / L finally to make acetylacetonate vanadyl complex Completely dissolved in acidic aqueous solution, then stirred in the air for 30min. After sealing the hydrothermal autoclave, place it in an oven at 200° C. for 30 h. After natural cooling, the obtained product was washed with deionized water and absolute ethanol to remove possible impurities. Figure 4 It is the FE-SEM picture of the smooth nanobelt obtained according to the embodiment. This solution is also applicable to the following combinations: 2mmol vanadium acetylacetonate complex+45ml water+0.5ml 1mol / L sulfuric acid; 2mmol o-vanadyl vanillic acid complex+45ml water+0.5ml 1mol / L hydrochloric acid or sulfuric acid; 2mmol VCl4+45ml Water+0.5ml 1mol / L hydrochloric acid; 2mmol V...

Embodiment 3

[0035] Nano-sized monoclinic VO 2 (VO 2 (M)) Realization of powder material nano-hexagonal flower: add 2mmol VOOH to 50ml polytetrafluoroethylene liner, add 45ml water, then add 1ml 1mol / L hydrochloric acid to completely dissolve VOOH in the aqueous solution, then add 3ml 0.1mol / L nitric acid, and stirred in the air for 10min. After sealing the hydrothermal autoclave, place it in an oven at 200° C. for 30 h. After natural cooling, the obtained product was washed with deionized water and absolute ethanol to remove possible impurities. Figure 5 It is the FE-SEM photograph of the hexagonal flower shape of the product obtained according to this embodiment. This experimental protocol is also applicable to the following combinations: 2mmol V(OH)2NH2+45ml water+2ml 0.1mol / L nitric acid or hydrogen peroxide; 2mmol V2O3+1ml nitric acid+45ml water+2ml 0.1mol / L hydrogen peroxide; 2mmol vanadium acetylacetonate complex +45ml water+2ml0.1mol / L nitric acid. This figure shows that diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com