High-nickel multi-element positive electrode material for lithium secondary battery, and preparation method thereof

A lithium secondary battery and cathode material technology, applied in secondary batteries, battery electrodes, electrical components, etc., can solve problems such as low initial discharge capacity, poor processing performance, and poor high-temperature storage performance, and achieve excellent abnormal temperature electrochemistry Good performance, good cycle performance, storage performance and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

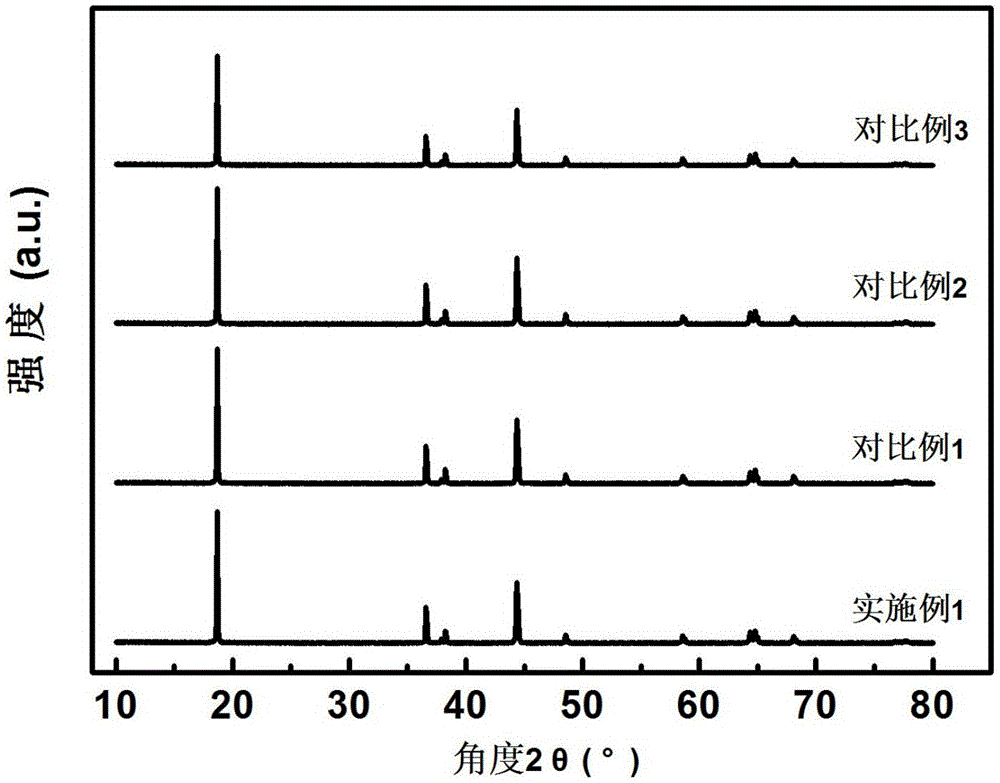

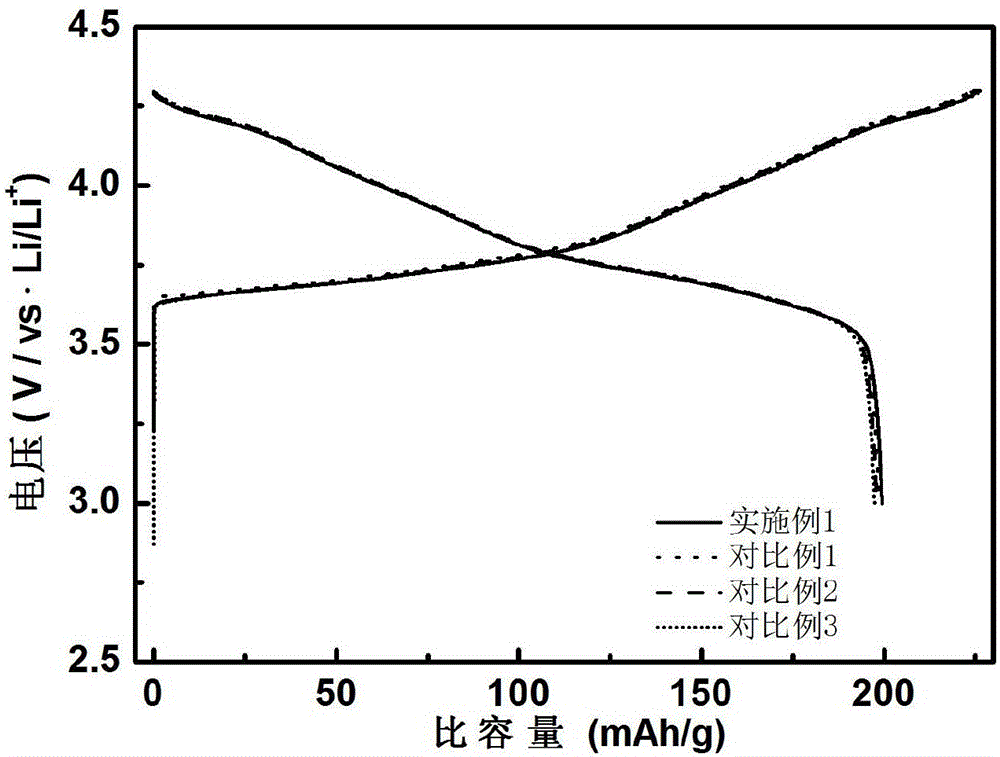

Embodiment 1

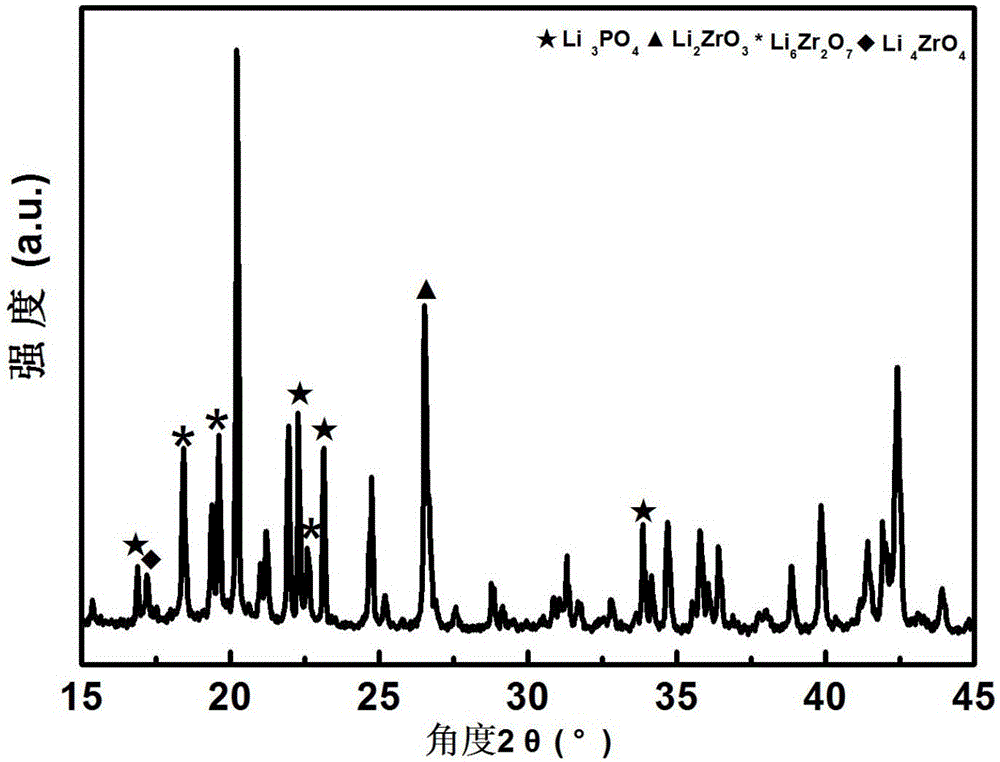

[0036] A high-nickel multi-element positive electrode material for a lithium secondary battery of the present invention, comprising a base material and a composite cladding layer outside the base material, the base material being the positive electrode material Li 1.05 Ni 0.8 co 0.1 mn 0.1 o 2 ; The composite coating layer uniformly coated on the outer surface of the substrate is a mixture of lithium zirconium oxide and lithium phosphorus oxide. Lithium zirconium oxide is Li 2 ZrO 3 , Li 6 Zr 2 o 7 and Li 4 ZrO 4 . Lithium phosphorus oxide is Li 3 PO 4 .

[0037] The content of the total impurity lithium on the surface of the high-nickel multi-element positive electrode material surface after the surface modification of the present embodiment is 0.070%, which is 0.32 times that before modification, and the Li in the total impurity lithium 2 CO 3 and LiOH content are 0.195% and 0.115%, respectively.

[0038] The preparation method of the high-nickel multi-elemen...

Embodiment 2

[0074] A high-nickel multi-component positive electrode material for a lithium secondary battery of the present invention, comprising a base material and a composite coating layer outside the base material, the base material being a binary positive electrode material Li 1.07 Ni 0.815 co 0.15 al 0.035 o 2 The composite coating layer uniformly coated on the outer surface of the substrate is a mixture of lithium zirconium oxide, lithium titanium oxide, lithium aluminum oxide and lithium phosphorus oxide. Lithium zirconium oxide is Li 2 ZrO 3 , lithium titanium oxide is Li 2 TiO 3 , lithium aluminum oxide is LiAlO 2 , the lithium phosphorus oxide is Li 3 PO 4 .

[0075] The content of the total impurity lithium on the surface of the high-nickel multi-element positive electrode material surface after the surface modification of this embodiment is 0.072%, which is 0.21 times that before modification, and the content of the total impurity lithium is the remaining Li on the ...

Embodiment 3

[0082] A high-nickel multi-component positive electrode material for a lithium secondary battery of the present invention, comprising a base material and a composite coating layer outside the base material, the base material being a binary positive electrode material Li 1.04 Ni 0.8 co 0.2 o 2 ; The composite coating layer uniformly coated on the outer surface of the substrate is a mixture of lithium zirconium oxide, lithium aluminum oxide and lithium phosphorus oxide. Lithium zirconium oxide is Li 2 ZrO 3 , lithium aluminum oxide is LiAlO 2 , the lithium phosphorus oxide is Li 3 PO 4 and Li 4 P 2 o 7 .

[0083] The content of the total impurity lithium on the surface of the high-nickel multi-element positive electrode material surface after the surface modification of this embodiment is 0.059%, which is 0.32 times that before modification, and the content of the total impurity lithium is the remaining Li on the surface of the substrate. 2 CO 3 and lithium element c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com