Intelligent no-mold drawing formation apparatus and process

A technology of dieless drawing and forming equipment, applied in the field of metal pressure processing, can solve the problems of difficulty in reasonable matching and precise control, poor dimensional uniformity of finished products, unstable product quality, etc., to achieve uniformity of structure and performance, reduce The effect of rolling deformation and stable continuous forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

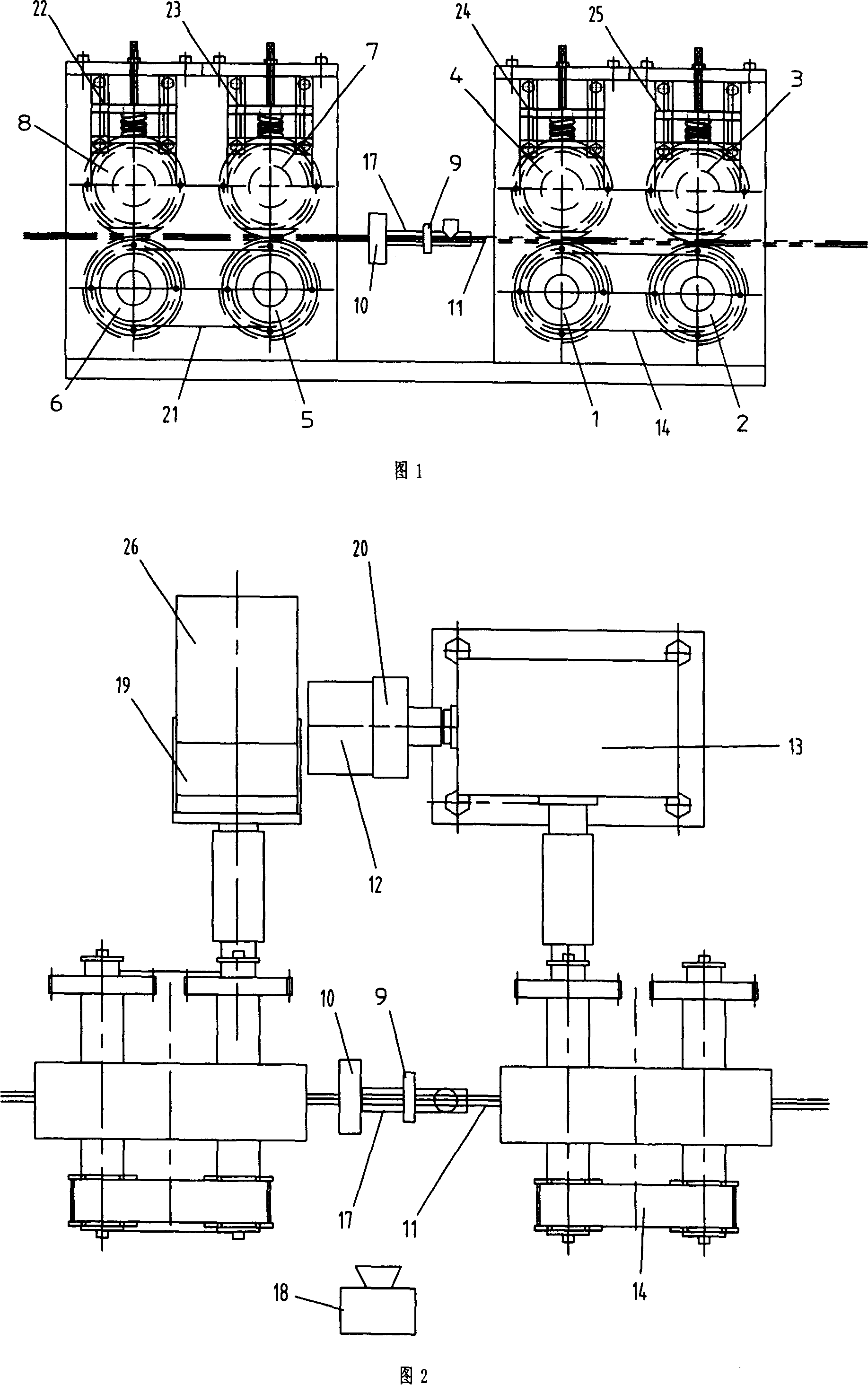

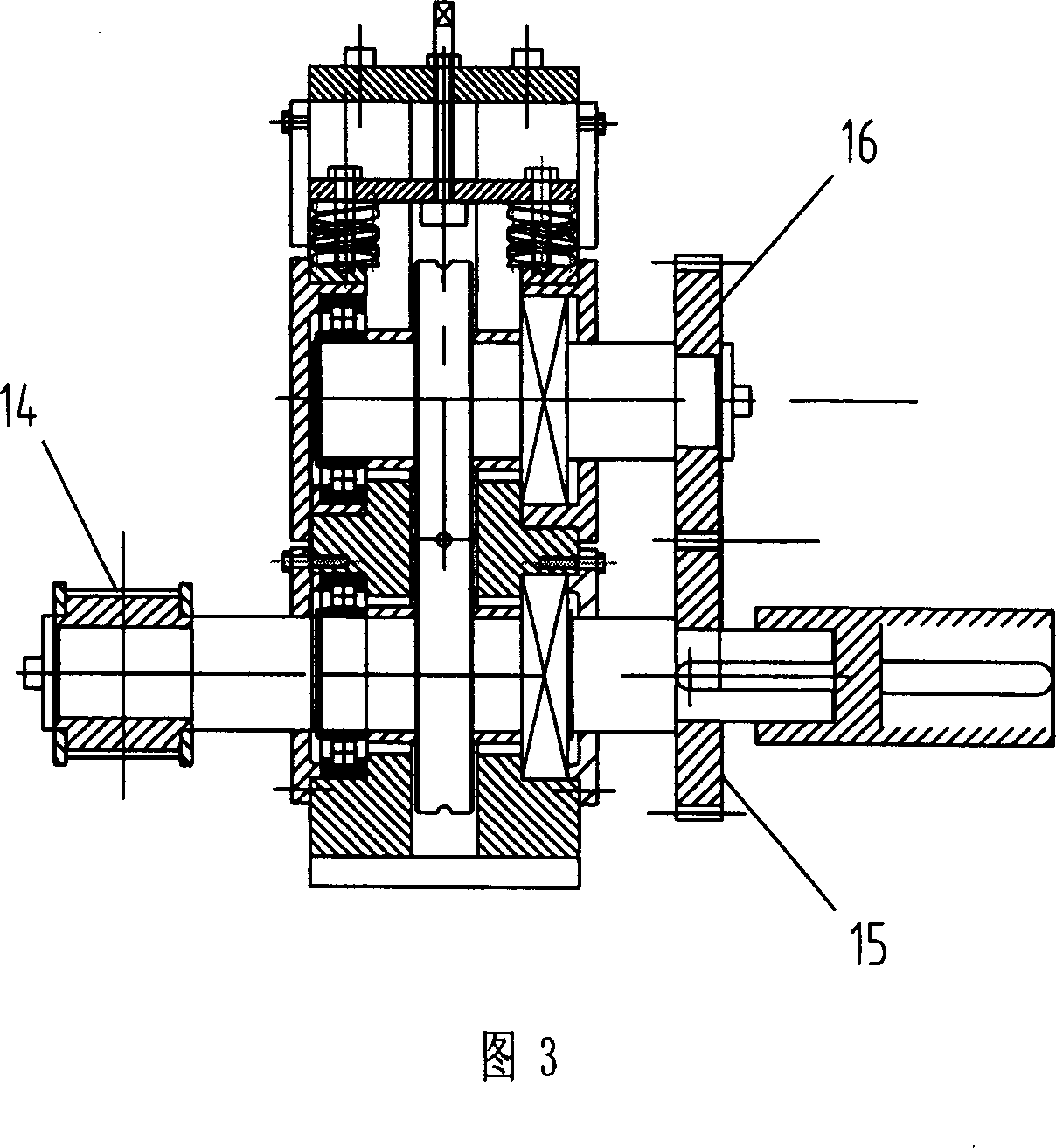

[0030]Embodiment 1: A nickel-titanium shape memory alloy wire rod containing Ni49at% and Ti51at% is selected as a billet, with a diameter of 6 mm, a rolling state, and a smooth surface. Loosen the pressing device 22, 23, 24, 25, and pass the blank to be drawn successively through the feeding rollers 2, 3, 1, 4 of the inventive device, the glass tube 17, the cooling water ring 10 and the pulling rollers 5, 7, 6 ,8. Adjust the pressing device 22, 23, 24, 25 to press the billet, start the computer and run the control program, input the target diameter, click the start drawing button, at this time, the equipment will execute the initial program according to the program design, that is, firstly, according to the target diameter and the actual measurement The billet diameter is designed to match the process parameters reasonably, the protective gas valve is opened, the air in the glass tube 17 is discharged, and then the feeding servo motor 12 and the traction servo motor 26 are sta...

Embodiment 2

[0031] Embodiment 2: The blank is an extruded high-copper-aluminum-copper alloy welding wire with an initial diameter of 6.1 mm and a smooth surface. By adopting the same operation process as that of Embodiment 1, a stable dieless drawing process can be realized, the area reduction rate reaches 22.5%, the finished product has stable dimensions, and the diameter fluctuation range is ±0.1mm.

Embodiment 3

[0032] Example 3: The blank is made of 304 stainless steel wire with an initial diameter of 6 mm and a smooth surface. By adopting the same operation process as that of Embodiment 1, a stable dieless drawing process can be realized, the reduction of area reaches 40%, the finished product has stable dimensions, and the diameter fluctuation range is ±0.1mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com