Method of forming powder compact and mold assembly for powder compaction

A technology of forming bodies and forming dies, which is applied in the direction of material forming presses, manufacturing tools, presses, etc., and can solve problems such as difficulty in producing formed bodies and lack of dense coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

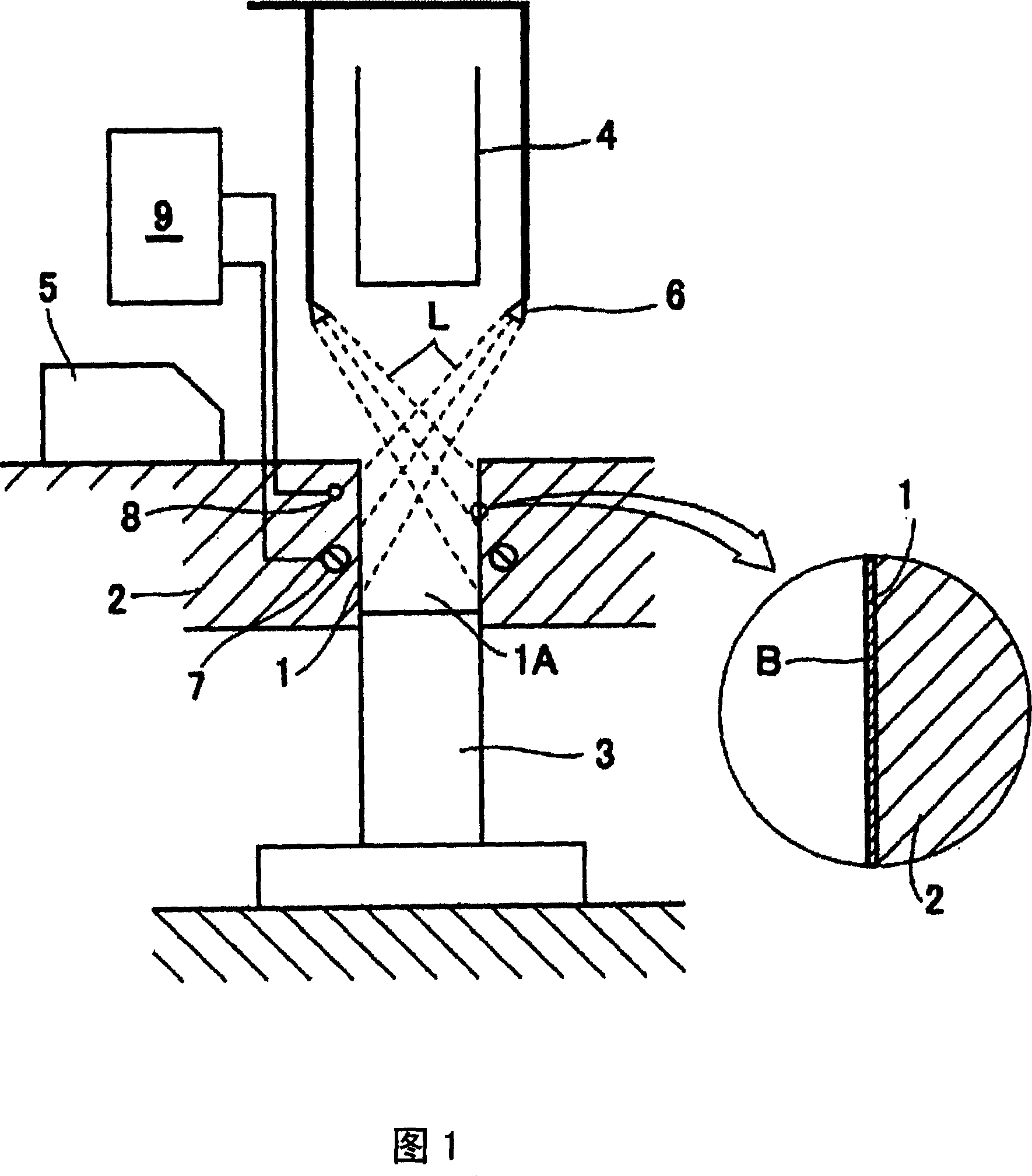

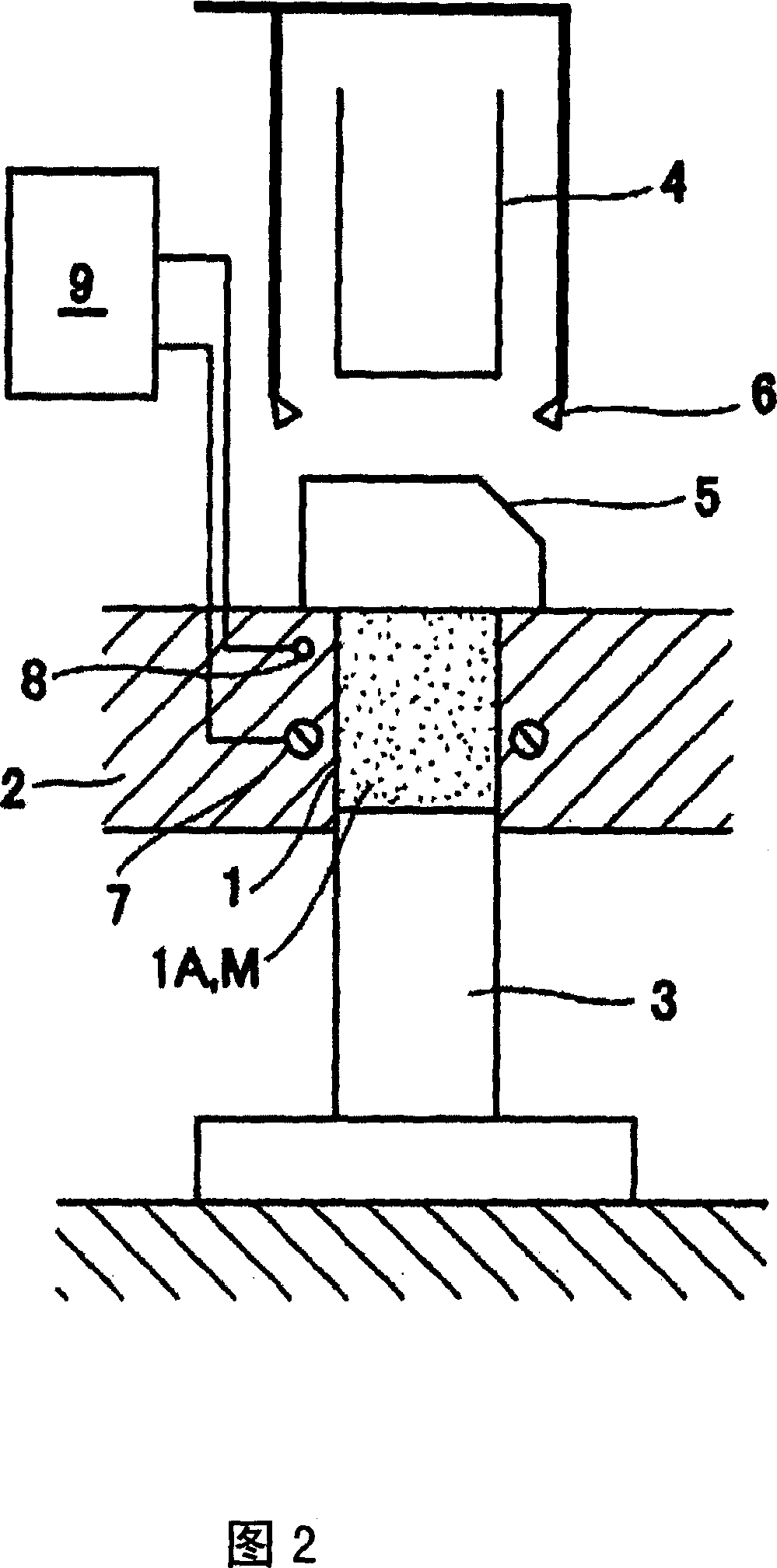

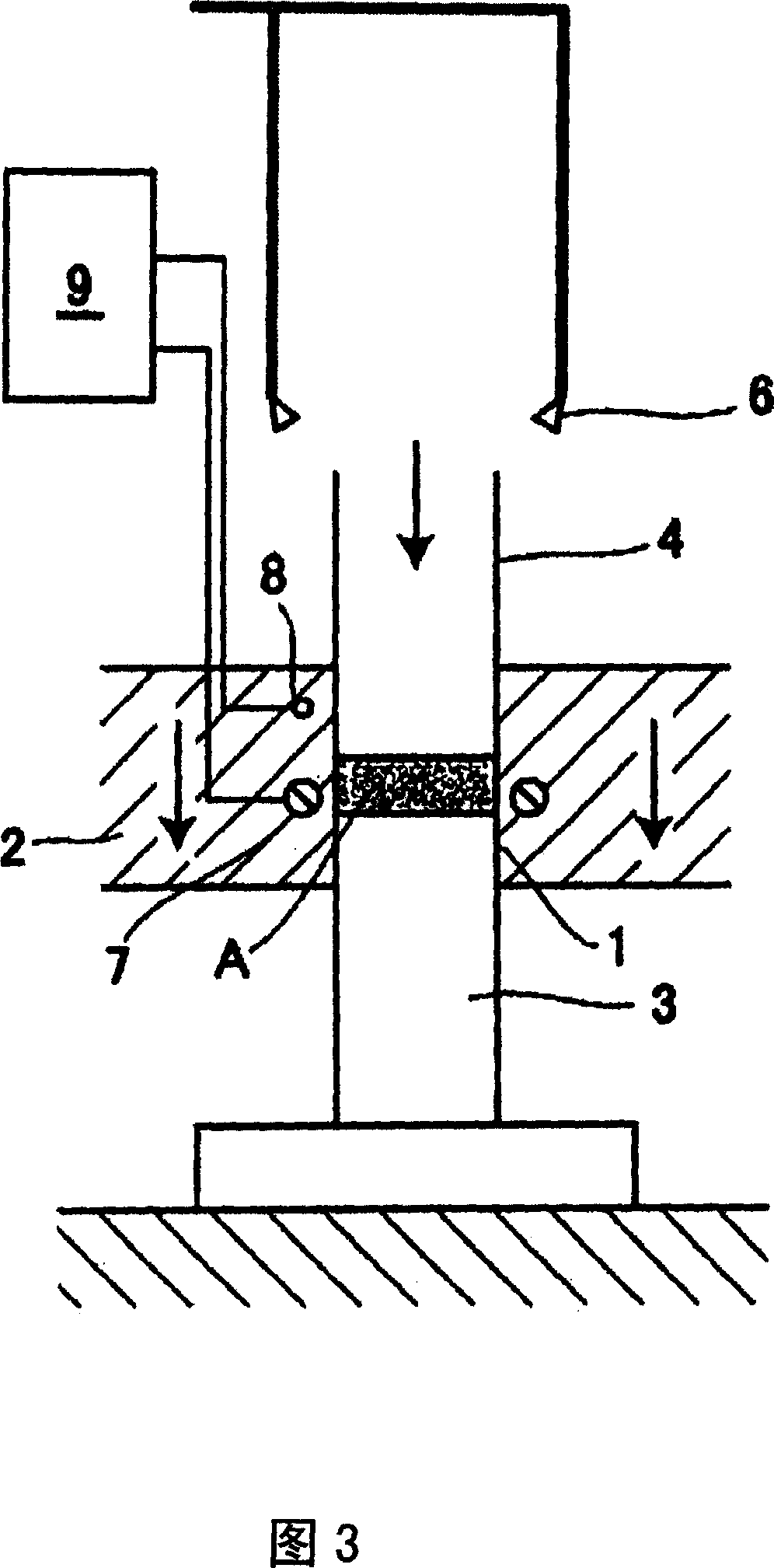

[0038] Hereinafter, a first embodiment of the present invention will be described with reference to FIGS. 1 to 4 . Fig. 1 shows the first step. In this figure, 1 is a through hole formed on the main body of the molding die 2, which is the side of the powder compact A, which will be described later. The lower punch 3 is closed, while the upper punch 4 is fitted from above the through hole 2 . Further, a feeder 5 which is a raw material supply body for supplying the raw material powder M is slidably provided on the upper surface of the die 2 . Moreover, above the through hole 2, there is provided a spraying unit 6, which is an attachment device for spraying an aqueous solution L of a lubricant to be described later, to adhere the aqueous solution L to the forming part 1A. It is connected to a tank (not shown) of the aqueous solution L through an automatic on-off valve (not shown). In addition, a heater 7 and a temperature detection part 8 are provided around the molding part 1...

Embodiment 2

[0067] 5 to 8 show the second embodiment, and the same reference numerals are assigned to the same parts as those of the above-mentioned embodiment 1, and detailed description thereof will be omitted. On the surface 10 of the through hole 1, in order to improve the wettability of the aqueous solution L on the surface 10, a surface treatment layer 11 is provided by performing a hydrophilic treatment and disposing a hydrophilic material. When the contact angle X of the above-mentioned surface treatment layer 11 and the above-mentioned aqueous solution L is smaller than the contact angle Y (X<Y) of the surface 10 formed by the material of the mold 2 itself or the top surface 2A of the directly exposed material and the above-mentioned aqueous solution L (X<Y), The aforementioned wettability can be improved. In addition, the measurement of the above-mentioned contact angles X and Y is not in the state illustrated for explanation, but is performed under the same conditions such as k...

Embodiment 3

[0075] 9 to 10 show the third embodiment, and the same reference numerals are attached to the same parts as those of the first and second embodiments described above, and the detailed description thereof will be omitted. In Example 2, in order to reduce the wettability of the above-mentioned aqueous solution L with respect to the above-mentioned top surface 2A on the top surface 2A of the mold 2 slidably provided with the feeder 5, that is, to improve the water repellency (hydrophobic) property, by performing Hydrophobic treatment, or disposing of a hydrophobic material to set up the surface treatment layer 21 . When the contact angle Y' of the above-mentioned surface treatment layer 21 with the above-mentioned aqueous solution L is greater than the contact angle X'(Y '>X'), the above-mentioned wettability can be reduced. The above-mentioned surface treatment layer 21 is formed of materials containing Si-H or C-H bonds, such as silicon-based resins or fluorine-based resins sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com