Hot-rolled wire rod for 1,960MPa-level cable rope galvanized steel wire and production method

A technology of galvanized steel wire and hot-rolled wire rod, which is applied in the field of hot-rolled wire rod, which can solve the problems of difficult to guarantee the torsional performance of steel wire, work hardening, and reduce plasticity, etc., achieve high tensile strength, reduce hardening, and ensure torsion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

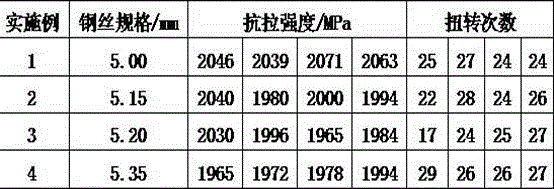

Examples

Embodiment 1

[0023] Embodiment 1: This 1960MPa grade cable galvanized steel wire hot-rolled wire rod is produced by the following process.

[0024] (1) Smelting process: molten iron is pretreated by desulfurization, LF furnace and RH vacuum refining treatment after smelting in top-bottom combined blowing converter, calcium line is fed to the molten steel before soft blowing to denature the inclusions in the steel, molten steel composition: C0.86 %, Si0.20%, Mn0.90%, Cr0.25%, Al0.040%, P0.010%, S0.005%, V0.07%, Cu0.02%, Ca0.0030%, the rest is Fe and unavoidable impurity elements.

[0025] (2) Continuous casting process: the treated molten steel is poured into a bloom with an end face size of 280mm×325mm, the superheat of the tundish is controlled at 20°C, the casting speed is controlled at 0.7m / min, and the solidification end is dynamic and lightly reduced. The total reduction of the slab is 10mm, the reduction passes are 4, the reduction of each pass is 2-4mm, and the C segregation index ...

Embodiment 2

[0031] Embodiment 2: The hot-rolled wire rod is produced by the following process.

[0032] (1) Smelting process: Desulfurization pretreatment of molten iron, LF furnace and RH vacuum refining treatment after smelting in top-bottom combined blowing converter, calcium feeding line before soft blowing of molten steel to denature inclusions in steel, molten steel composition: C0.85 %, Si0.60%, Mn0.80%, Cr0.30%, Al0.020%, P0.012%, S0.008%, V0.06%, Cu0.05%, Ca0.0025%, the rest is Fe and unavoidable impurity elements.

[0033] (2) Continuous casting process: the treated molten steel is poured into a bloom with an end face size of 280mm×325mm, the superheat of the tundish is controlled at 25°C, the casting speed is controlled at 0.5m / min, and the solidification end is dynamic and lightly reduced. The total reduction of the slab is 12mm, the reduction passes are 5, the reduction of each pass is 2-4mm, and the C segregation index of the slab center is 1.06; the continuous casting slab...

Embodiment 3

[0039] Embodiment 3: The hot-rolled wire rod is produced by the following process.

[0040] (1) Smelting process: Desulfurization pretreatment of molten iron, LF furnace and RH vacuum refining treatment after smelting in the top-bottom combined blowing converter, denaturation treatment of inclusions in steel by feeding calcium line before soft blowing of molten steel, molten steel composition: C0.91 %, Si1.00%, Mn0.70%, Cr0.35%, Al0.015%, P0.008%, S0.015%, V0.02%, Cu0.10%, Ca0.0020%, the rest is Fe and unavoidable impurity elements.

[0041] (2) Continuous casting process: the processed molten steel is poured into a bloom with an end face size of 280mm×325mm, the superheat of the tundish is controlled at 30°C, the casting speed is controlled at 0.6m / min, and the solidification end is dynamic and softly reduced. The total reduction of the slab is 13mm, the reduction passes are 5, the reduction of each pass is 2-4mm, and the C segregation index of the slab center is 1.06; the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com