Integral extrusion molding manufacturing method of truss-type leg chords of jack-up platform

A self-elevating platform and manufacturing method technology, applied in the direction of metal extrusion dies, water conservancy projects, artificial islands, etc., can solve the problems of large welding shrinkage deformation, reduced welding efficiency, and large welding workload, and achieve fast forming speed, Reduced welding workload and fast manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Now according to the manufacture of the leg chord of the 400-foot jack-up drilling platform as an example, this manufacturing method is further described:

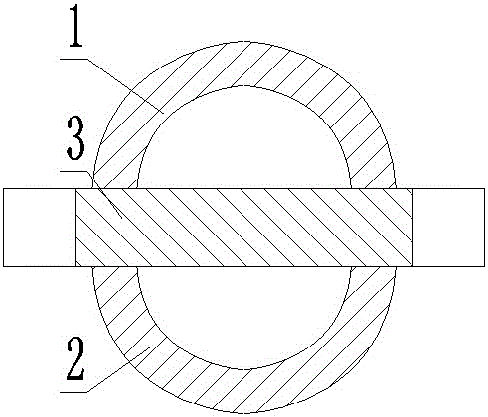

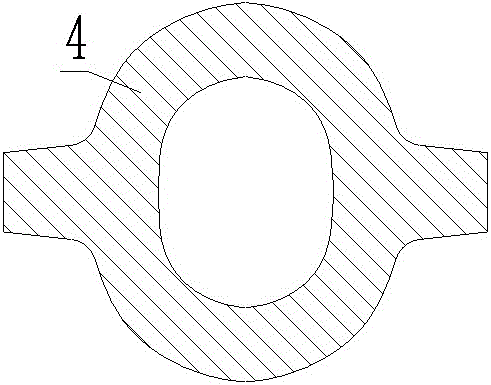

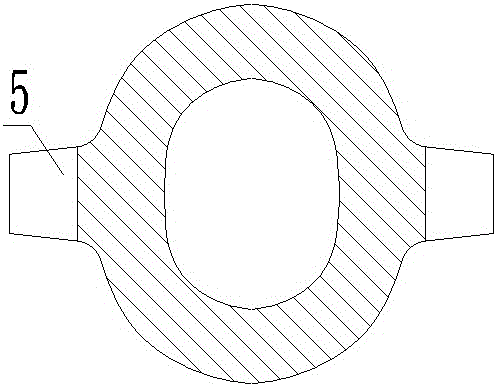

[0044] 1. Determine the material weight of the steel ingot: optimize the calculation of the section parameters, such as figure 1 Shown is the typical section form of the chord assembly manufactured by welding, such as figure 2 As shown, it is the full section form of the chord after extrusion molding; in order to ensure that the bearing capacity of the chord structure manufactured as a whole is not lower than that of the welded structure, the weight of the structure can basically be kept unchanged or reduced without affecting the structure connected to it The overall size of the piece has changed a lot. Through calculation, the 9m chord is obtained, and the weight of the extruded billet required is 20 tons. In addition to the process requirements, the ingot shape of the steelmaking ingot is determined to be 28 tons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com