Connection node between the lower steel beam of the roof natural ventilator and the roof steel beam or steel roof truss

A natural ventilator and connection node technology, applied in the direction of roofing, roof cladding, construction, etc., can solve the problems of increasing steel consumption, increasing welding workload, waste, etc., to reduce steel consumption, reduce steel girder splicing nodes, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

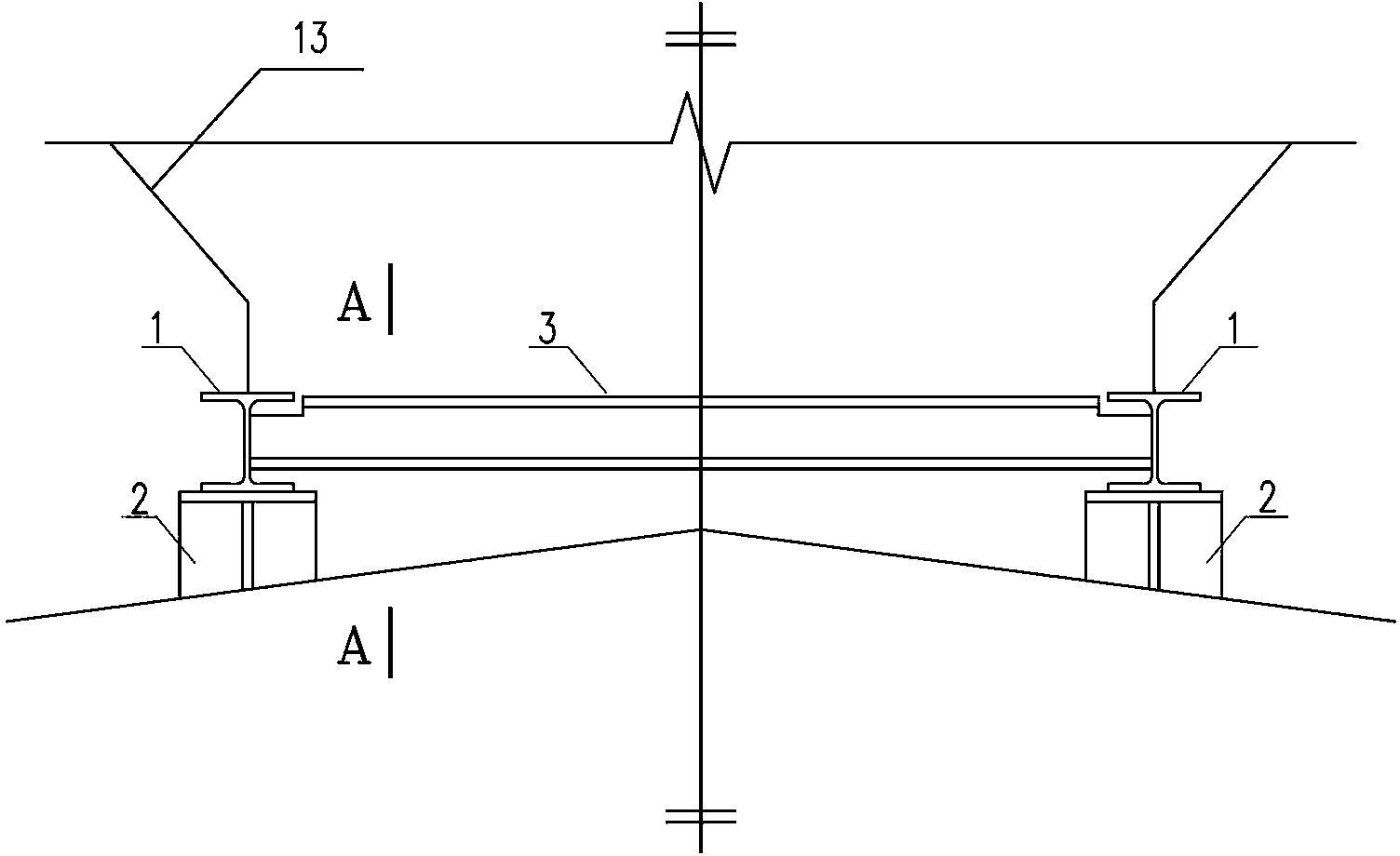

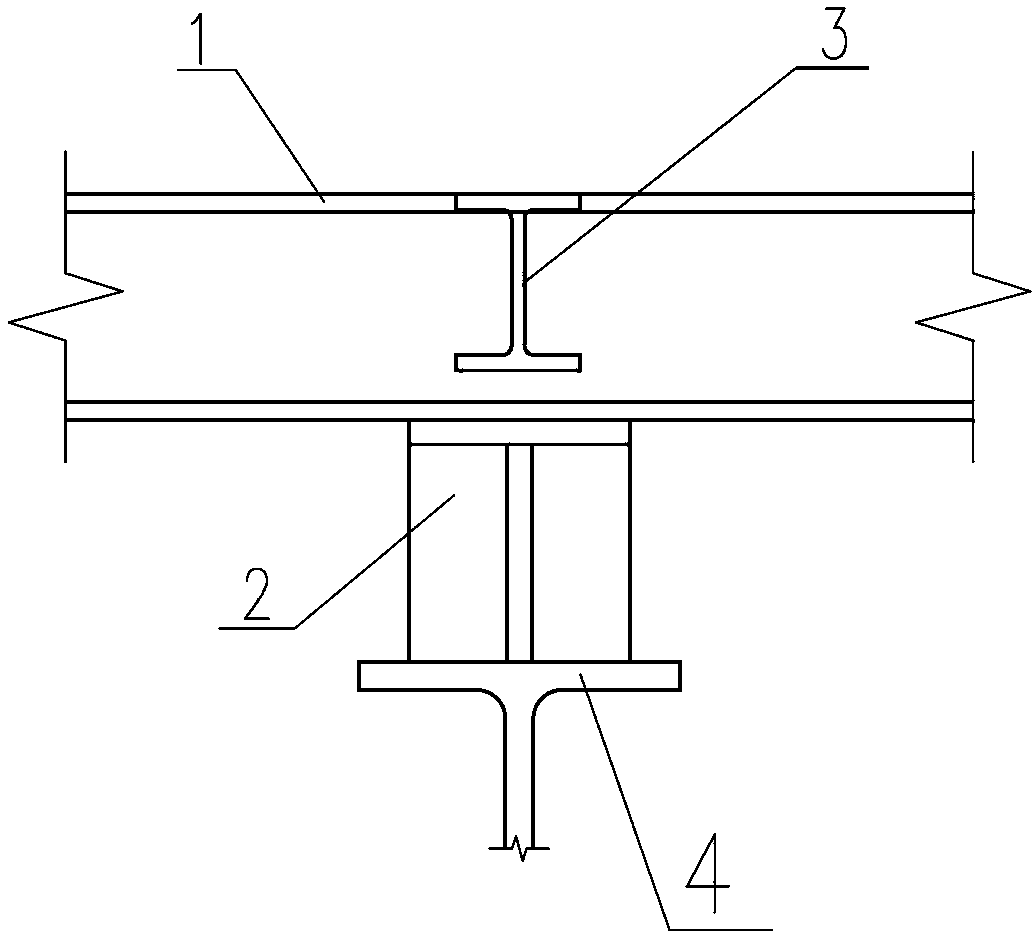

[0026] As shown in the figure, the lower steel beam of the roof natural ventilator of the present invention is connected to the roof steel beam or the steel roof truss, including the lower steel beam 1 of the ventilator, and the lower steel beam 1 of the ventilator is arranged under the roof natural ventilator 13, and the lower steel beam of the ventilator The steel beam is H-shaped steel, the lower flange of the lower steel beam 1 of the ventilator is placed on the steel support support plate 10 on both sides of the steel support vertical plate 7, and the lower steel beam of the ventilator on both sides of the steel support vertical plate 7 1. The web is connected to the upper stiffener 9 of the steel support through bolts 6, the upper flange of the lower steel beam 1 of the ventilator is connected to the top plate 11 of the steel support through the connecting cover plate 5, and the upper stiffener 9 of the steel support is set on the steel support Between the bracket support...

Embodiment 2

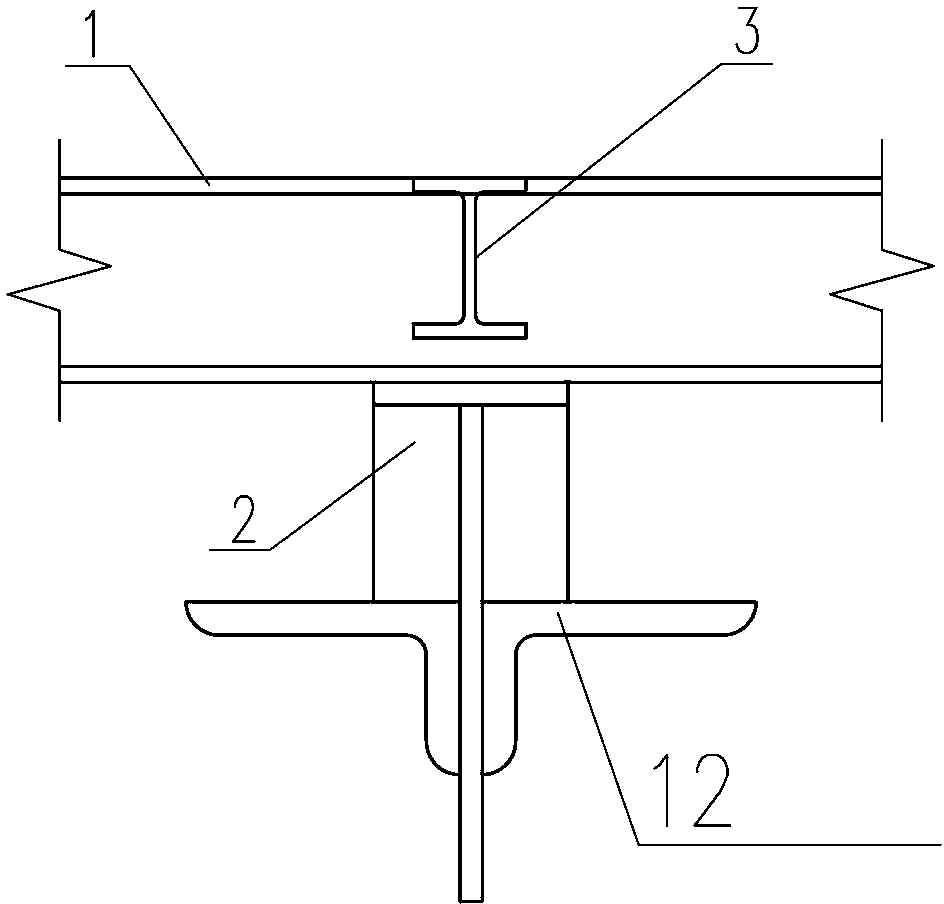

[0028] When the upper flange 4 of the roof steel beam in Embodiment 1 is the upper chord 12 of the steel roof truss, the steel support vertical plate 7 is the roof truss gusset plate, and the steel support support plates 10 and the steel roof truss upper chord 12 on both sides of the roof truss gusset plate are respectively provided with Stiffener 8 at the lower part of the steel bracket, the lower stiffener 8 of the steel bracket is welded with the support plate 10 of the steel bracket and the upper chord 12 of the steel roof truss, and the connection between the gusset plate of the roof truss and the lower stiffener 8 of the steel bracket and the upper chord 12 of the steel roof truss is continuous The fillet weld, the gusset plate of the roof truss passes through the upper chord 12 of the steel roof truss, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com