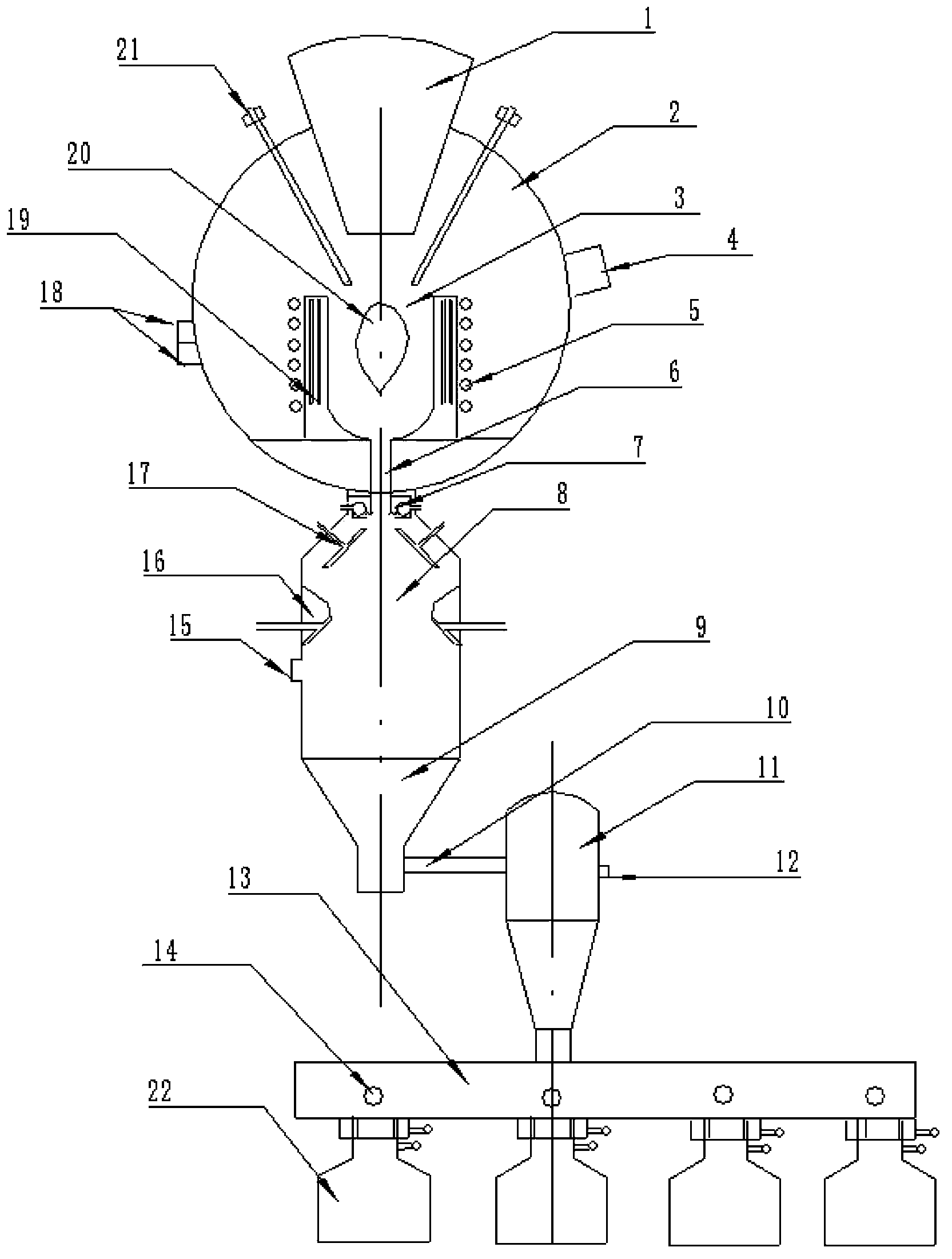

Ti-based powder preparing device and Ti-based powder preparing method

A powder, titanium-based technology, applied in the field of vacuum magnetic levitation to prepare high-purity titanium-based powder, can solve the problems of low purity, pollution, high cost, etc., and achieve the effect of low oxygen content, high purity, and pollution solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1, Ti6Al4V powder with an average particle size of 20 μm, a purity of 4N, a spheroidization rate of 90%, an oxygen content of less than 2000 ppm, and a nitrogen content of less than 500 ppm. The main parameters of the preparation process are: the purity of the Ti6Al4V furnace charge is 2N -3N, system vacuum 6×10 -4 MPa, the oxygen content of the system is less than 1ppm, the power supply is 200Kw, the supersonic high-pressure argon pressure is 5.23MPa, the vibration frequency is 85HKz, and the argon pressure of the two-stage cooling device is 0.6MPa.

Embodiment 2

[0040] Example 2, the average particle size is 20 μm, the purity is 4N, the spheroidization rate is 90%, the oxygen content is lower than 1800ppm, and the pure powder with nitrogen content is lower than 300ppm. The main parameters of the preparation process are: the purity of the pure titanium charge is at 2N-3N, system vacuum 6×10 -5 MPa, the oxygen content of the system is less than 1ppm, the power supply is 200Kw, the supersonic high-pressure argon pressure is 5.23MPa, the vibration frequency is 85HKz, and the argon pressure of the two-stage cooling device is 0.6MPa.

[0041] The titanium-based powder material is prepared by a vacuum magnetic levitation smelting powder-making device, which improves the purity of the titanium-based powder material, reduces the oxygen content and nitrogen content of the material, and has a high powder spheroidization rate and good sphericity. It can be well used in the traditional powder metallurgy industry and the emerging laser 3D printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com