Titanium-based powder material preparing device

A powder material, titanium-based technology, applied in the field of equipment for preparing titanium-based powder materials, can solve the problems of low purity, pollution, high energy consumption, etc., and achieve the effects of low oxygen content, pollution solving, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

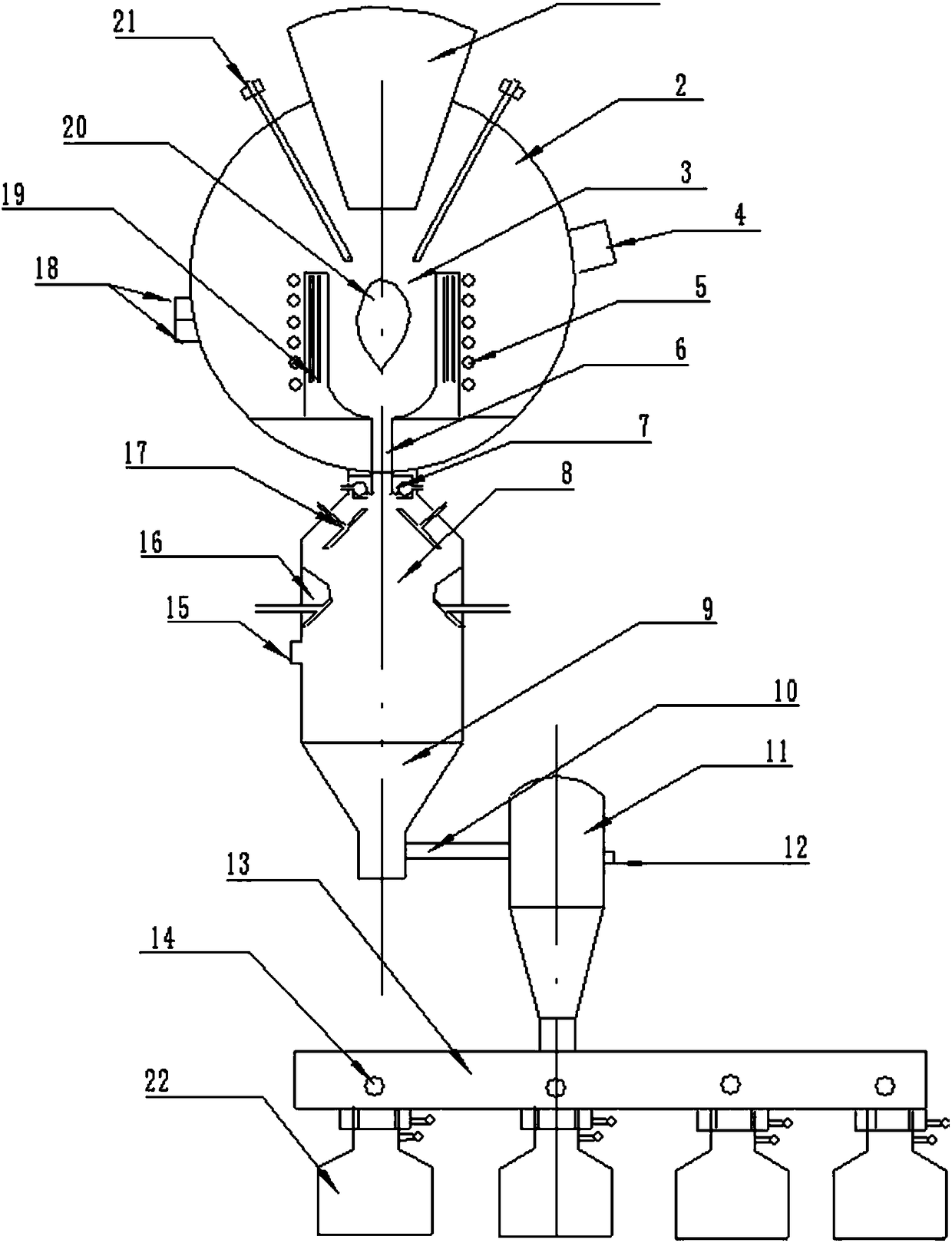

[0040] Example 1, Ti with an average particle size of 20 μm, a purity of 4N, a spheroidization rate of 90%, an oxygen content of less than 2000 ppm, and a nitrogen content of less than 500 ppm 6 Al 4 V powder, the main parameters of the preparation process are: Ti 6 Al 4 The purity of V charge is 2N-3N, and the vacuum degree of the system is 6×10 -4 MPa, the oxygen content of the system is less than 1ppm, the power supply is 200Kw, the supersonic high-pressure argon pressure is 5.23MPa, the vibration frequency is 85HKz, and the argon pressure of the two-stage cooling device is 0.6MPa.

Embodiment 2

[0041] Example 2, the average particle size is 20 μm, the purity is 4N, the spheroidization rate is 90%, the oxygen content is lower than 1800ppm, and the pure powder with nitrogen content is lower than 300ppm. The main parameters of the preparation process are: the purity of the pure titanium charge is at 2N-3N, system vacuum 6×10 -5 MPa, the oxygen content of the system is less than 1ppm, the power supply is 200Kw, the supersonic high-pressure argon pressure is 5.23MPa, the vibration frequency is 85HKz, and the argon pressure of the two-stage cooling device is 0.6MPa.

[0042] The titanium-based powder material is prepared by a vacuum magnetic levitation smelting powder-making device, which improves the purity of the titanium-based powder material, reduces the oxygen content and nitrogen content of the material, and has a high powder spheroidization rate and good sphericity. It can be well used in the traditional powder metallurgy industry and the emerging laser 3D printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com