High-entropy alloy powder containing amorphous nanocrystalline and fabrication method thereof

An amorphous nanocrystalline and high-entropy alloy technology is applied in the field of high-entropy alloy powder containing amorphous nanocrystalline and its preparation, which can solve the problems of narrow application range, low powder sphericity, unsuitable for spraying materials, etc. Scope of application, effect of optimizing the structure and properties of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

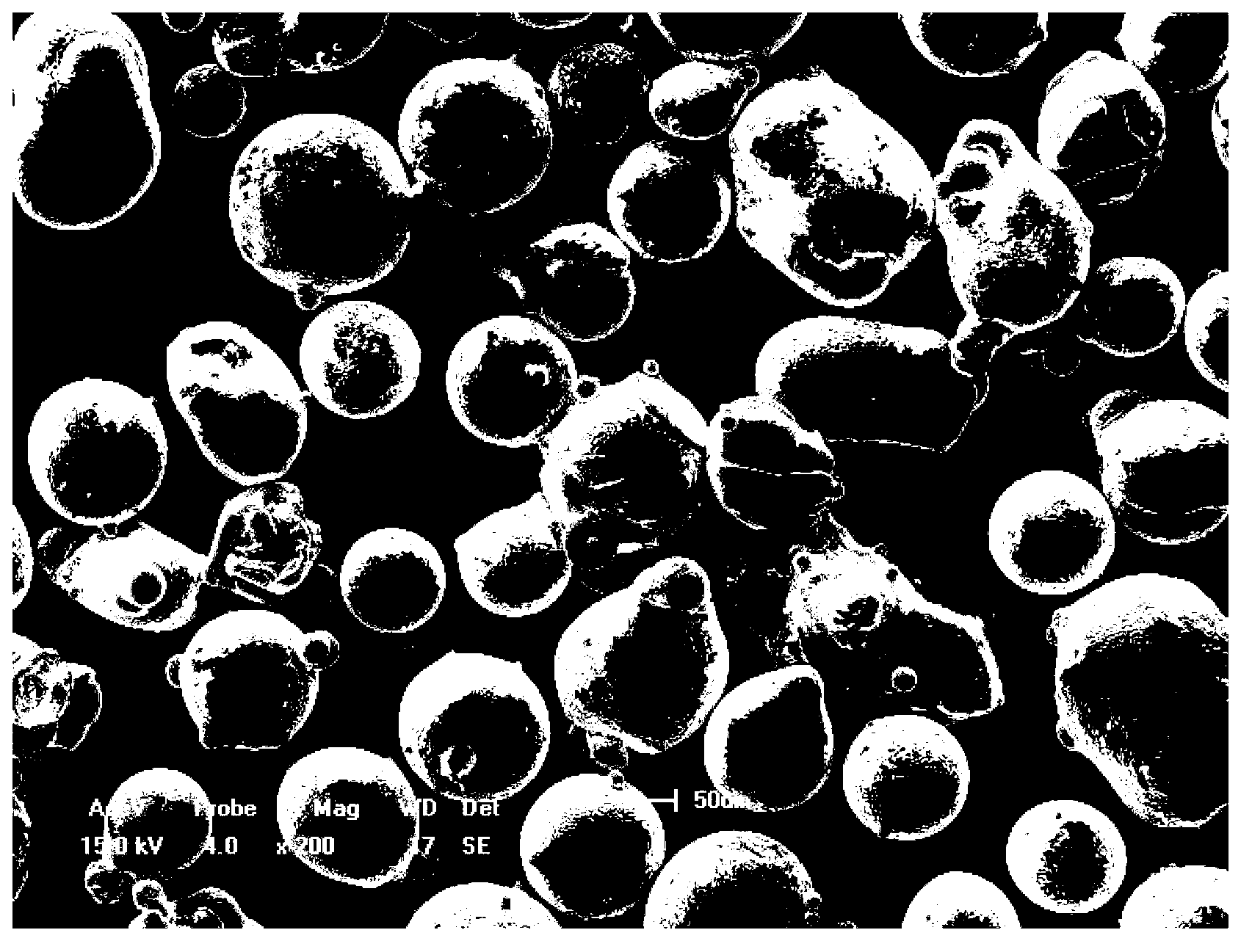

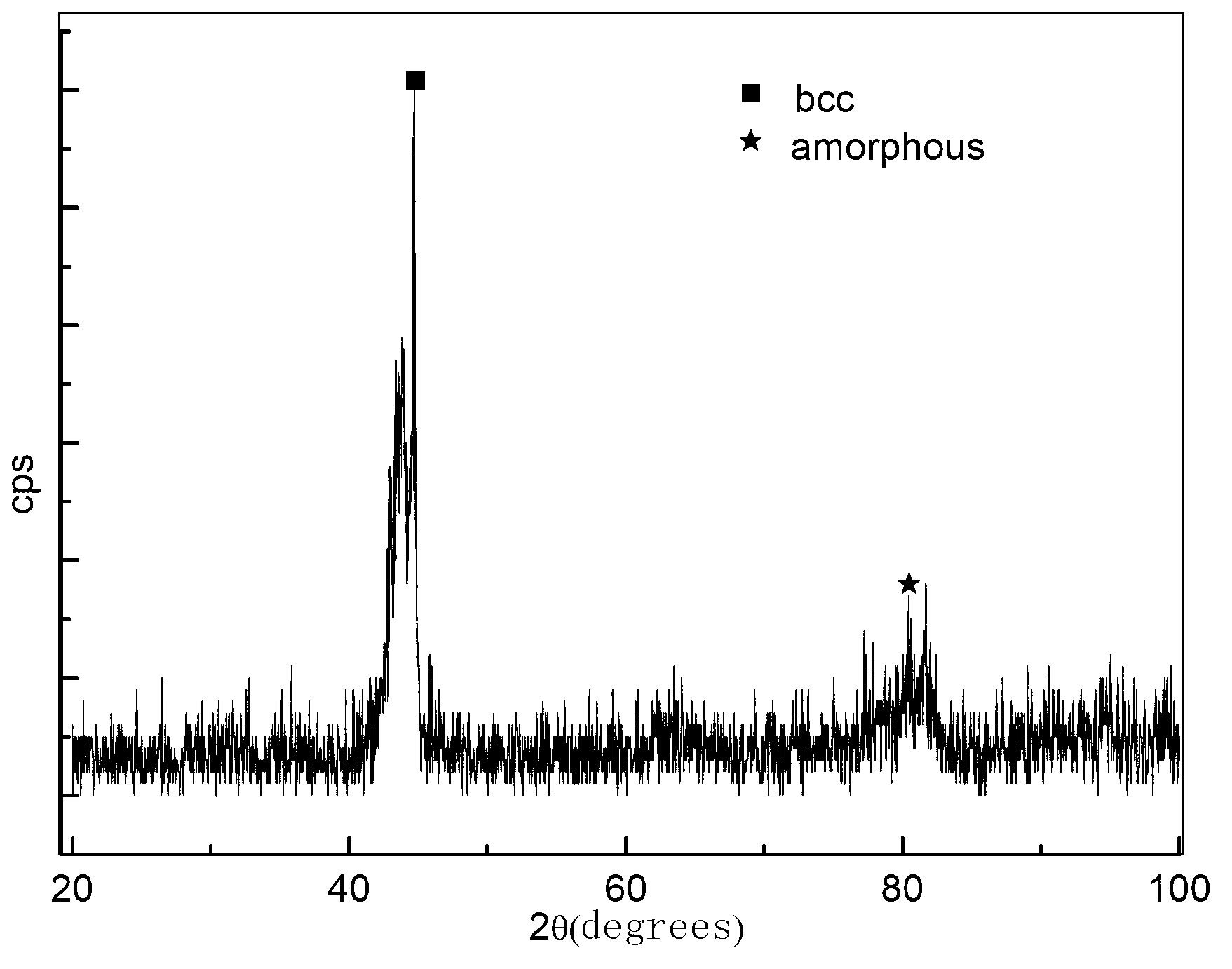

Embodiment 1

[0017] 1) Weigh the metal raw materials from which impurities and oxide films have been removed by nearly equal atomic percentages, and the total percentage is 100%, of which Al: 14.3%, Fe: 14.3%, Co: 14.3%, Ni: 14.3%, Cr: 14.3% , Mo: 14.3%, Si: 14.2%, the total percentage is 100%, put them into the corundum crucible in order of melting point from low to high, and then evacuate until the air pressure is lower than 6×10 -2 MPa, filled with argon, the argon pressure is 3×10 -2 The smelting starts under the condition of Pa, the smelting current is 75A, the smelting time is 25min, and electromagnetic stirring is introduced to reduce the segregation of alloy components. After the smelting is completed, the alloy solution is cast into the magnesia mold shell to obtain a high-entropy alloy master alloy with uniform composition.

[0018] 2) Heat the high-entropy alloy master alloy with the induction coil in the atomization equipment to melt, keep overheating, and form a metal liquid ...

Embodiment 2

[0021] 1) Weigh the metal raw materials from which impurities and oxide films have been removed by nearly equal atomic percentages, and the total percentage is 100%, of which Al: 14.3%, Fe: 14.3%, Co: 14.3%, Ni: 14.3%, Cr: 14.3% , Mo: 14.3%, Si: 14.2%, the total percentage is 100%, put them into the corundum crucible in order of melting point from low to high, and then evacuate until the vacuum degree is lower than 6×10 -2 MPa, filled with argon, the argon pressure is 3×10 -2 The smelting starts under the condition of Pa, the smelting current is 75A, the smelting time is 25min, and electromagnetic stirring is introduced to reduce the segregation of alloy components. After the smelting is completed, the alloy solution is cast into the magnesia mold shell to obtain a high-entropy alloy master alloy with uniform composition.

[0022] 2) Heat the high-entropy alloy master alloy with the induction coil in the atomization equipment to melt, keep overheating, and form a metal liquid...

Embodiment 3

[0025] 1) Weigh the metal raw materials from which impurities and oxide films have been removed by nearly equal atomic percentages, and the total percentage is 100%, of which Al: 14.3%, Fe: 14.3%, Co: 14.3%, Ni: 14.3%, Cr: 14.3% , Mo: 14.3%, Si: 14.2%, the total percentage is 100%, put them into the corundum crucible in order of melting point from low to high, and then evacuate until the vacuum degree is lower than 6×10 -2 MPa, filled with argon, the argon pressure is 3×10 -2 The smelting starts under the condition of Pa, the smelting current is 75A, the smelting time is 25min, and electromagnetic stirring is introduced to reduce the segregation of alloy components. After the smelting is completed, the alloy solution is cast into the magnesia mold shell to obtain a high-entropy alloy master alloy with uniform composition.

[0026]2) Heat the high-entropy alloy master alloy with the induction coil in the atomization equipment to melt, keep overheating, and form a metal liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com