Method and device for preparing crack-free cladding layer through ultrasonic vibration-assisted laser cladding

An auxiliary laser and ultrasonic vibration technology, applied in the coating, metal material coating process and other directions, can solve the problems of increasing the heating process, the effect of vibration and stirring is not obvious, and the effect of stress homogenization in the micro-region of the molten pool is weakened, so as to improve the temperature. and stress distribution, ensuring synchronization and timeliness, and strengthening the effect of engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

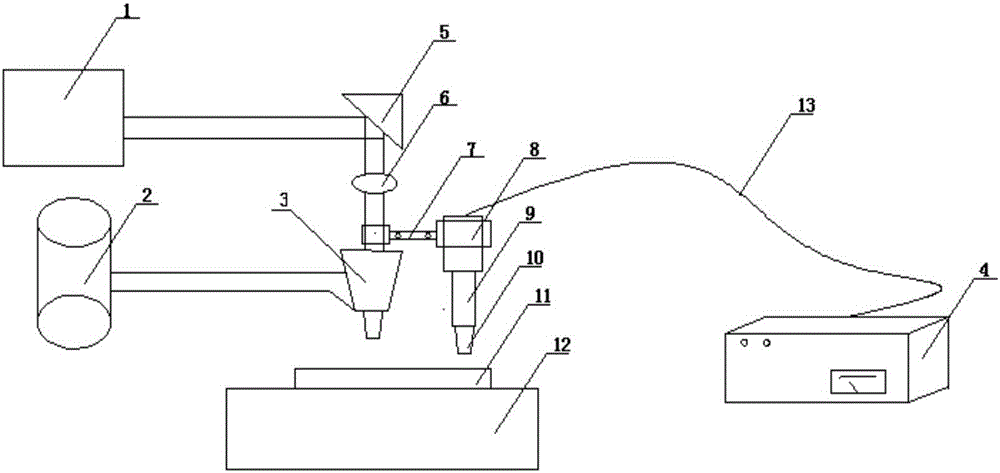

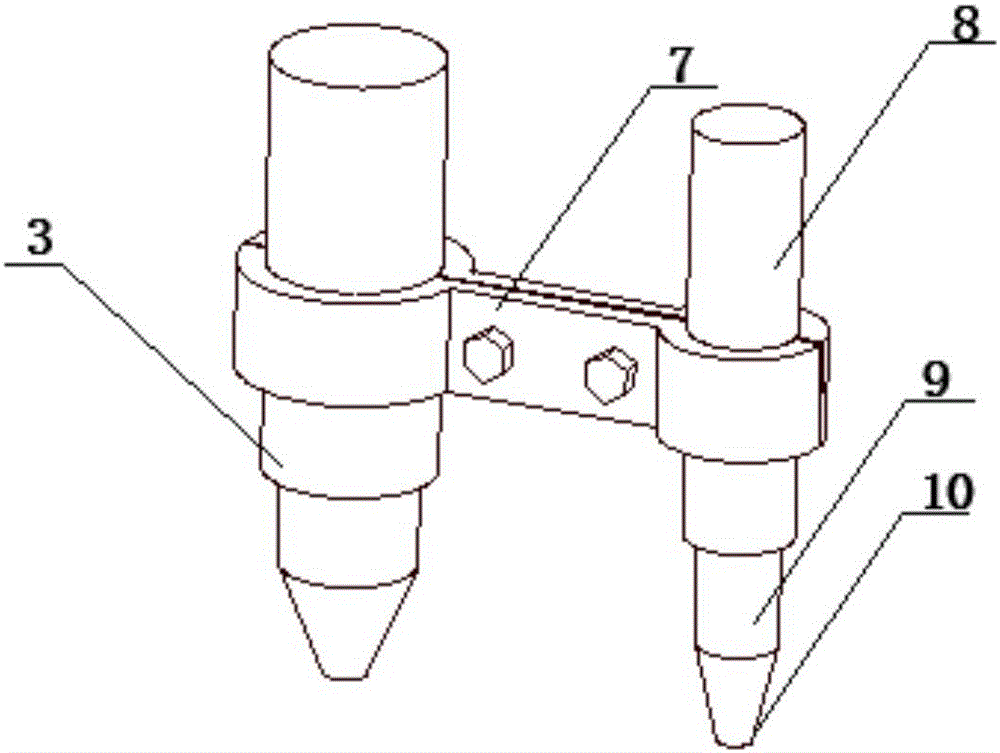

[0028] Such as figure 1 and figure 2 As shown, the device for preparing crack-free cladding layer by ultrasonic vibration-assisted laser cladding in the present invention includes a laser generator [1], a powder feeder [2], a laser head [3], an ultrasonic generator [4], Mirror [5], focusing lens [6], fixture [7], transducer [8], horn [9], vibrator [10], cladding layer [11], substrate [12] and cable [ 13]. Before the experiment, the substrate [12] was polished and the surface was wiped with acetone to remove impurities, the powder feeder [2] was connected to the laser generator [1] to prepare powder for the cladding process, and the ultrasonic generator [4] was connected with the cable [13]. Connect with the transducer [8], connect the horn [9] and vibrator [10] to the end of the transducer [8] at the same time to form a complete ultrasonic emission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com