Rolling bearing failure diagnostic method based on multi-characteristic parameter

A kind of rolling bearing and fault diagnosis technology, applied in the direction of mechanical bearing testing, biological neural network model, etc., can solve the problems of single characteristic parameter neural network input vector, unable to fully reflect the fault state of rolling bearing, unable to better reflect the nature of the signal, etc. Achieving the effect of high diagnostic accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

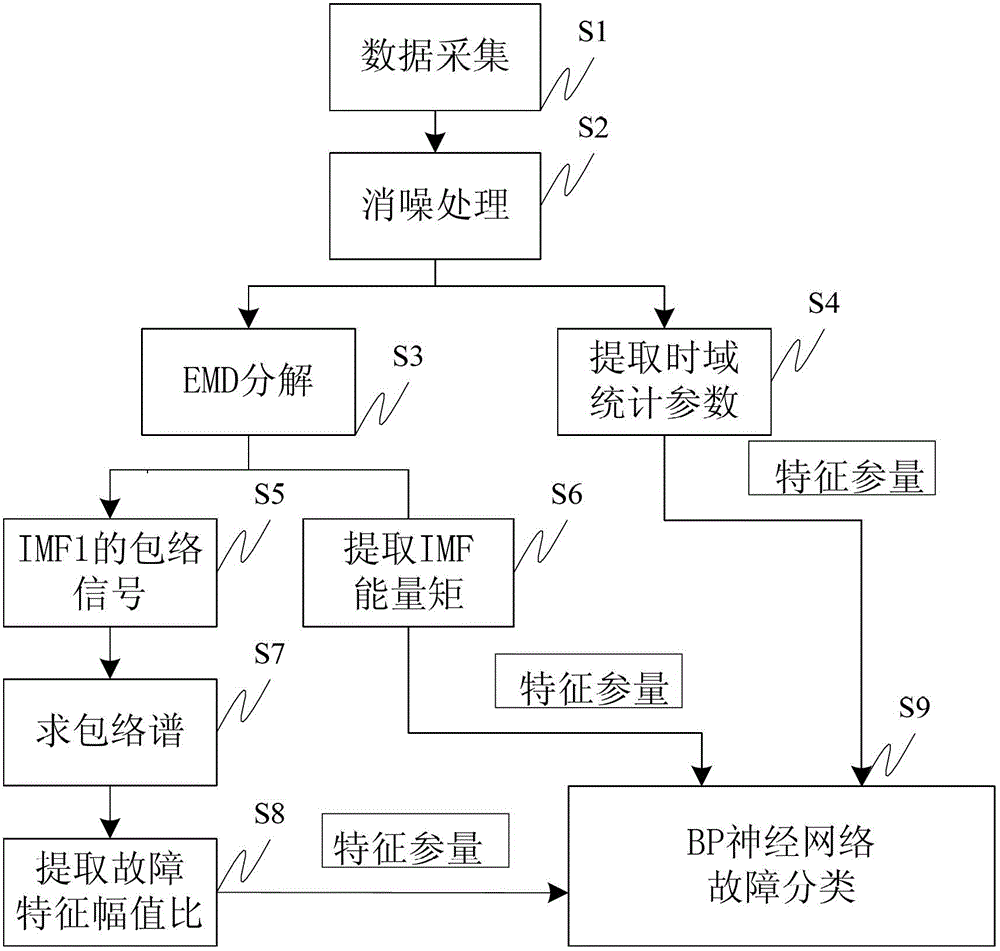

[0030] Refer to the following Figure 1-8 Examples of the present invention will be described.

[0031] In order to make the above objects, features and advantages more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] Such as figure 1 As shown, a rolling bearing fault diagnosis method based on multi-characteristic parameters includes the following steps:

[0033] (1) Vibration signal preprocessing steps

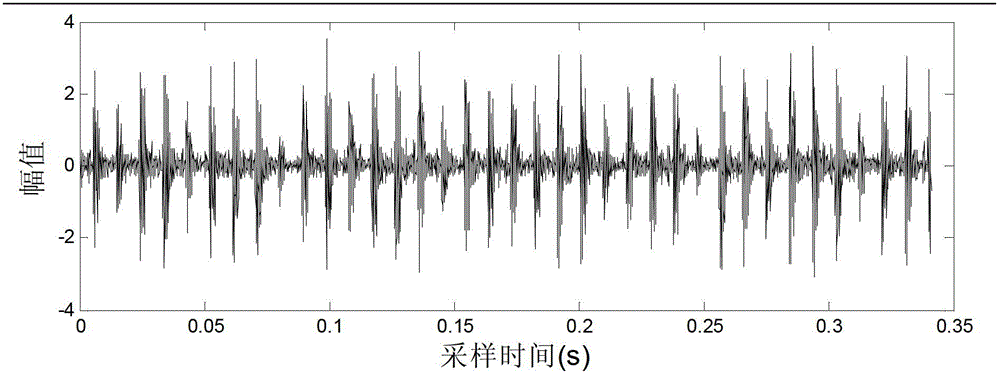

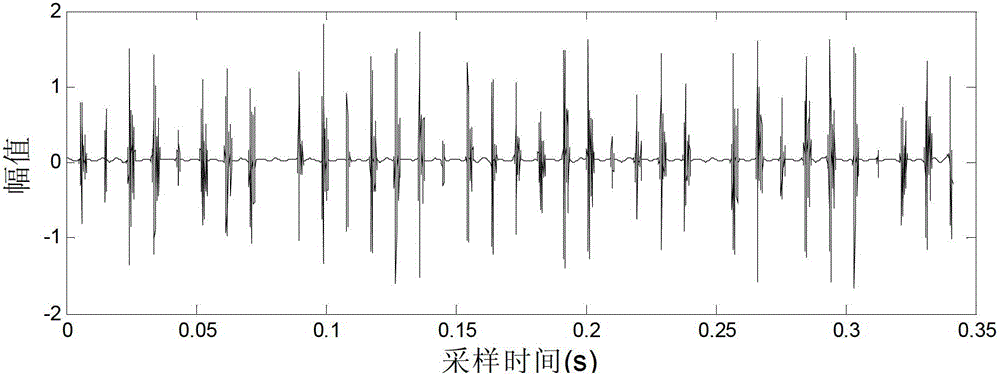

[0034] Including: data collection step S1 and denoising processing step S2. Rolling bearings are often affected by the vibration of nearby equipment and other external factors during operation. In practical applications, it is necessary to denoise the signal to remove background noise and improve the reliability of fault diagnosis. The collected original vibration signal x(t) of the rolling bearing with outer ring fault is as follows: figure 2 shown. The comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com