A Method of Obtaining Air Leakage of Turbine Shaft Sealing System

A shaft seal system and air leakage technology, which is used in fluid tightness testing, machine/structural component testing, and measuring devices, etc., can solve problems such as difficulty in ensuring steam turbine efficiency and low accuracy in calculating shaft seal air leakage. , to achieve the effect of ensuring safety, efficiency, and accurate reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings.

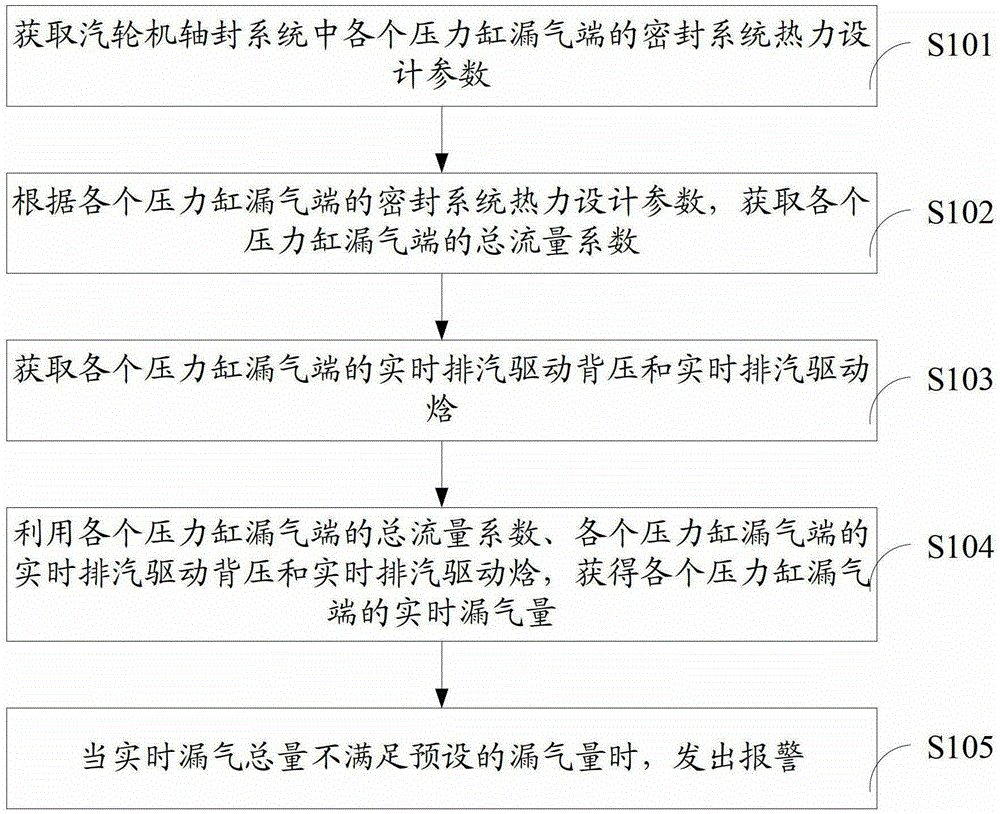

[0017] This invention proposes a method for obtaining the air leakage of the shaft seal system of a steam turbine, please refer to figure 1 , including the steps:

[0018] S101. Obtain the thermal design parameters of the sealing system at the air leakage ends of each pressure cylinder in the shaft sealing system of the steam turbine;

[0019] The thermal design parameters of the sealing system obtained include: the theoretical air leakage volume of each leakage end, the theoretical exhaust driving back pressure of each leakage end, and the theoretical exhaust driving enthalpy of each leakage end.

[0020] S102. According to the thermal design parameters of the sealing system at the air leakage end of each pressure cylinder, obtain the total flow coefficient of the air leakage end of each pressure cylinder;

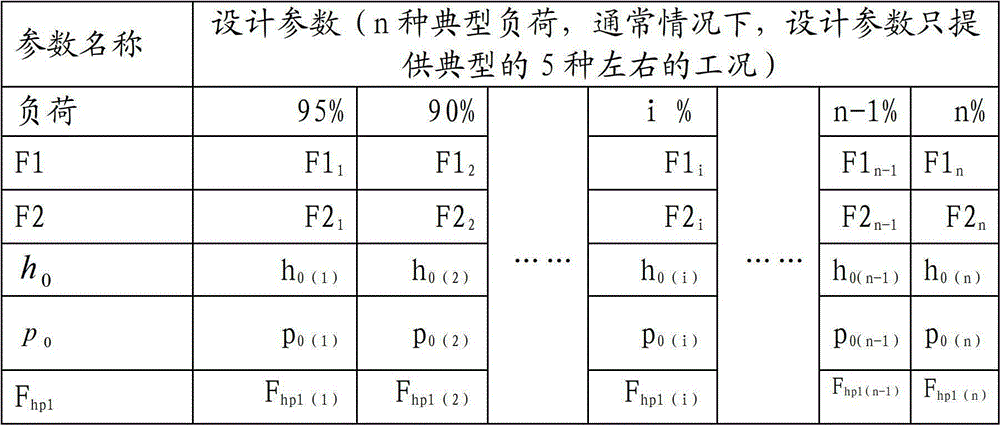

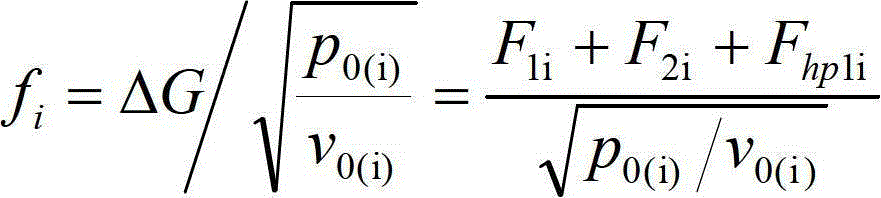

[0021] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com