Using method for numerical control dual-flying-saw cold slitting machine

A flying saw and cutting machine technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems that the production efficiency of the flying saw machine has not been improved, the production efficiency needs to be improved, and the NC programming is complicated, so as to reduce the failure Hidden dangers, improved production efficiency, and easy NC programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific embodiments.

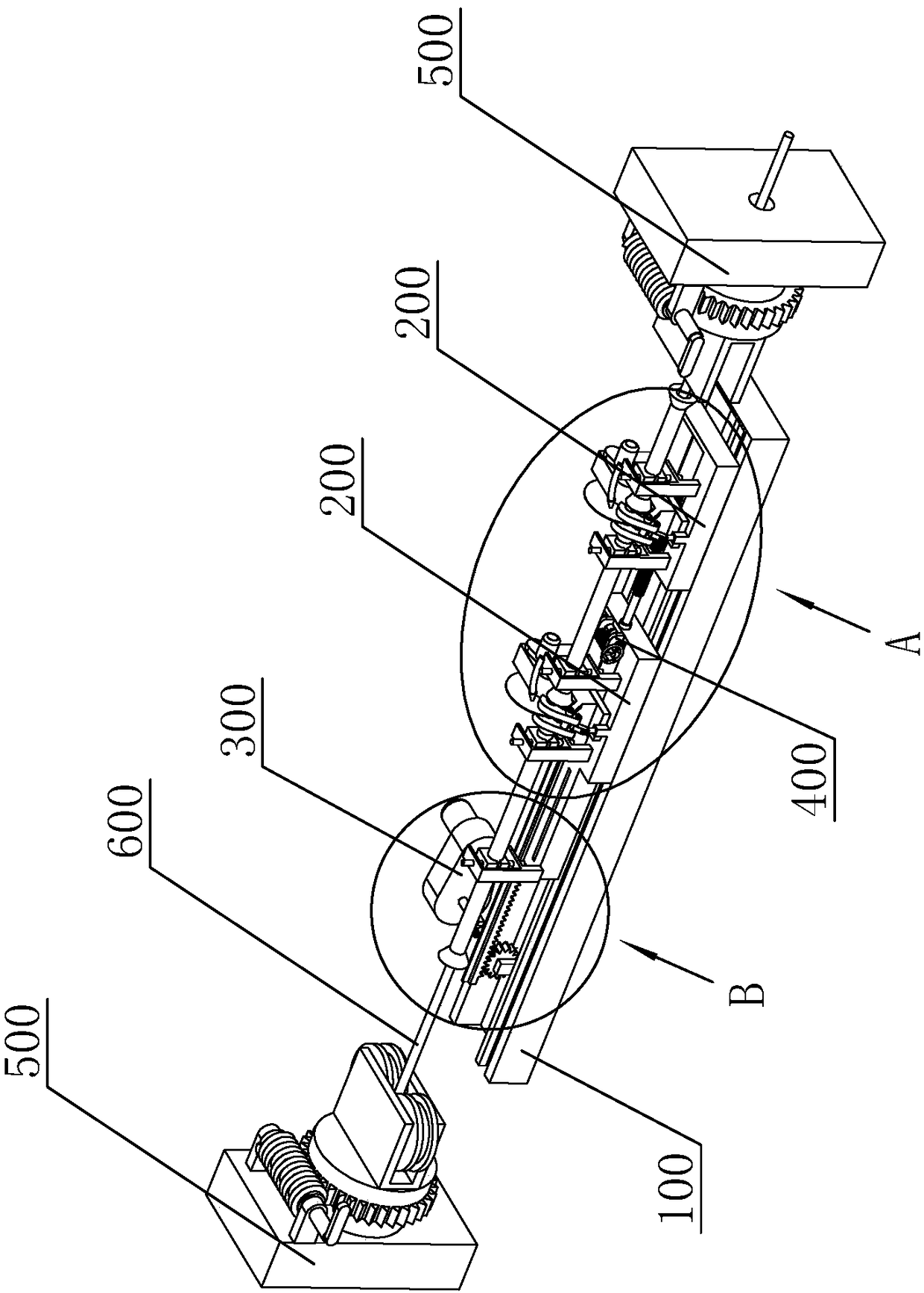

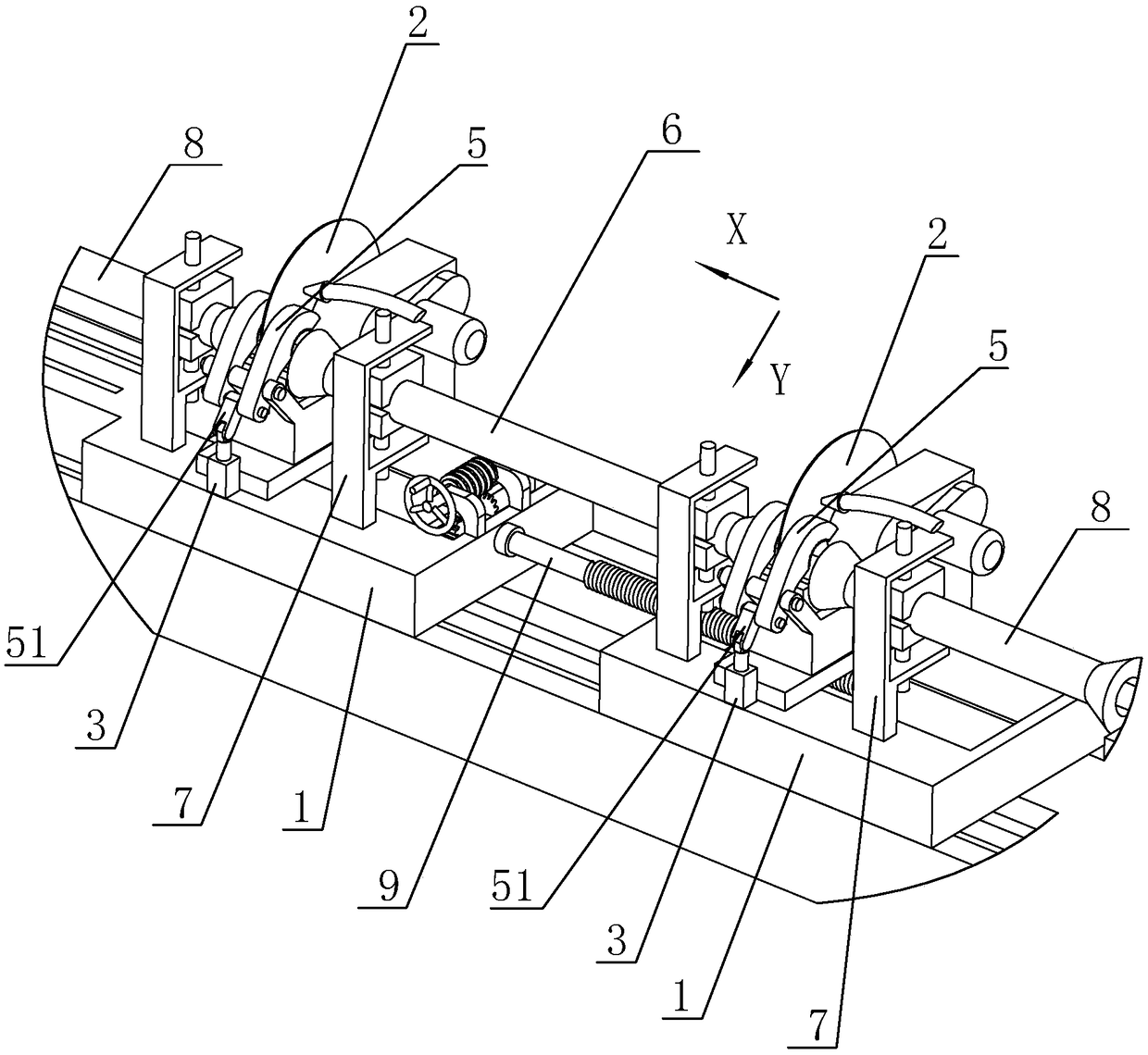

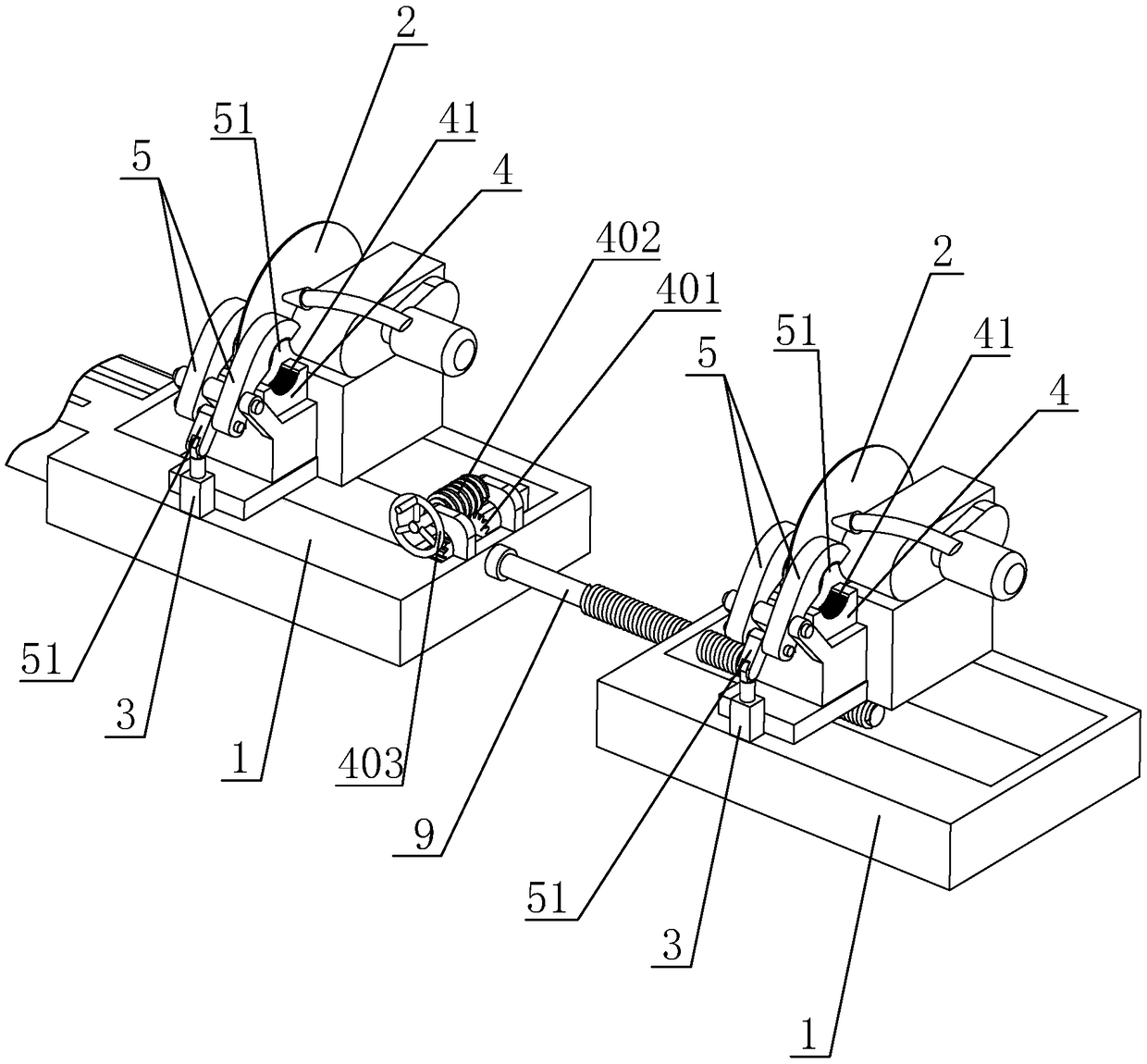

[0036] Such as figure 1 and figure 2 As shown, the CNC double flying saw cold cutting machine of the present invention includes a workbench 100, two sets of flying saw devices 200 slidably arranged on the workbench 100, a traverse drive unit 300, a distance adjuster 400 and a guide Wheel device 500.

[0037] The two sets of flying saw devices 200 are connected to each other through the adjustable screw rod 9, and are driven by the traversing drive unit 300 to slide synchronously on the workbench 100 left and right. A pulley that is slidably matched with the slide rail is provided, and the axis of the screw rod 9 and the lateral movement direction of the flying saw device 200 ( figure 2 X direction shown in ), one end of the screw rod 9 is rotatably arranged on the base 1 of one of the flying saw devices 200, and the base 1 of the other flying saw device 200 is fixed with a nut thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com