Operating modal parameter identification method for principal component analysis on basis of wavelet threshold denoising

A technology of wavelet threshold denoising and principal component analysis, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as unsatisfactory denoising results and distorted original input signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

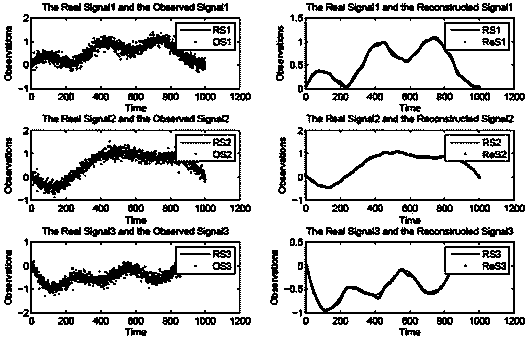

[0066] The simply supported beam with a length of 1m is divided into 1000 equal parts at equal intervals, and a total of 1001 response measuring points are generated. At the frequency points 205, 91.3, 366, 572, 824, 1121, and 22HZ, the multi-frequency sinusoidal loads with corresponding powers of 60, 30, 30, 30, 30, 30, and 30 units were respectively loaded on a 0.2m unit The response data is obtained at the point position, the sampling time is 1s, the sampling frequency interval is 4096HZ, and 1% Gaussian measurement noise is added to the response signal. Using the SymN wavelet function, the adaptive threshold is calculated by sqrt(2*log(length(X))). The experiment selects the response data of the 1st, 400th, and 500th times containing 15% Gaussian white noise as test data.

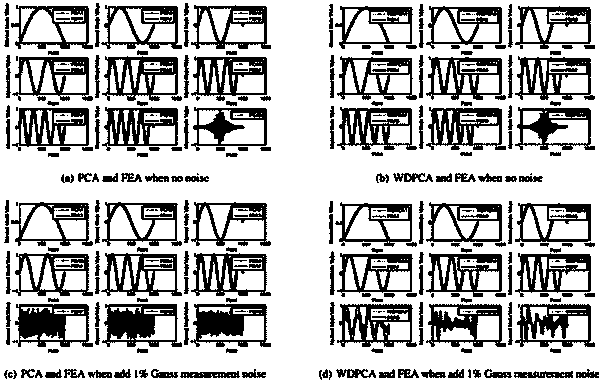

[0067] As shown in Figure 6, due to the relatively small contribution rate of the fifth principal component, the fifth-order mode shape is missing, which is an inherent characteristic of the principal ...

Embodiment 2

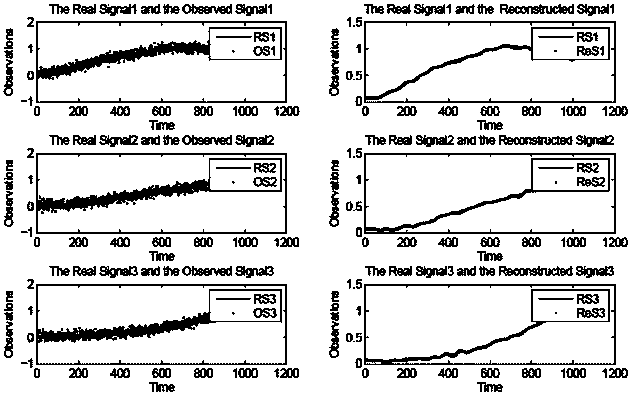

[0076] The cantilever beam with a length of 1m is divided into 1000 equal parts at equal intervals, and a total of 1001 response measurement points are generated, and a modal damping of 0.01 is added. The same white noise is applied at each node, the sampling time is 1s, the sampling frequency interval is 4096HZ, and 10% Gaussian measurement noise is added to the response signal. The SymN wavelet function is used in the experiment, and the adaptive threshold is calculated by sqrt(2*log(length(X))). The experiment selects the 20th, 1000th, 4000th response data containing 10% Gaussian white noise as test data.

[0077] As shown in Figure 6, comparing (a) and (c) in Figure 6(2), it is found that the PCA method is sensitive to measurement noise, which leads to mode loss in the case of noise, such as the 6th and 7th modes; comparison (c) and (d) in Figure 6(2) found that the fifth mode can be identified by PCA after wavelet denoising. As shown in Figure 7, comparing (c) and (d) i...

Embodiment 3

[0084] A cylindrical shell with simply supported boundary conditions at both ends is excited by uniform reverberation Gaussian white noise. The parameters of the cylindrical shell are: thickness 0.005m, length 0.37m, radius 0.1825m, elastic modulus 205GPa, material Poisson's ratio 0.3, material density 7850kg / m 3 ; The modal damping ratio η is 0.03, 0.05, 0.10 respectively. The sampling frequency is set to 5120Hz, and the sampling time is set to 1s. The LMS Virtual.lab finite element method is used for calculation, and the structural displacement response data in the X, Y, and Z directions of three different damping ratios are obtained from each observation point to form a set of response data in the three directions.

[0085] Such as Figure 8 As shown, the accuracy of the modal parameters gradually decreases with the increase of the modal damping, and the sixth mode is lost due to the small contribution rate of the principal components. Therefore, the modal parameter iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com