Electronic product vibration DLP method based on cross-power spectrum function mode parameter identification

A technology of modal parameter identification and cross-power spectrum, which is applied in measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

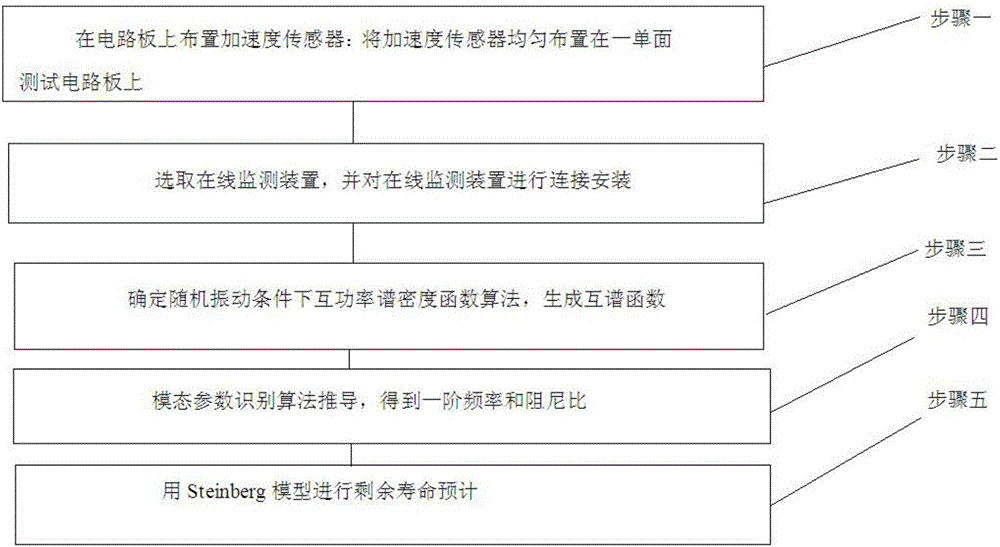

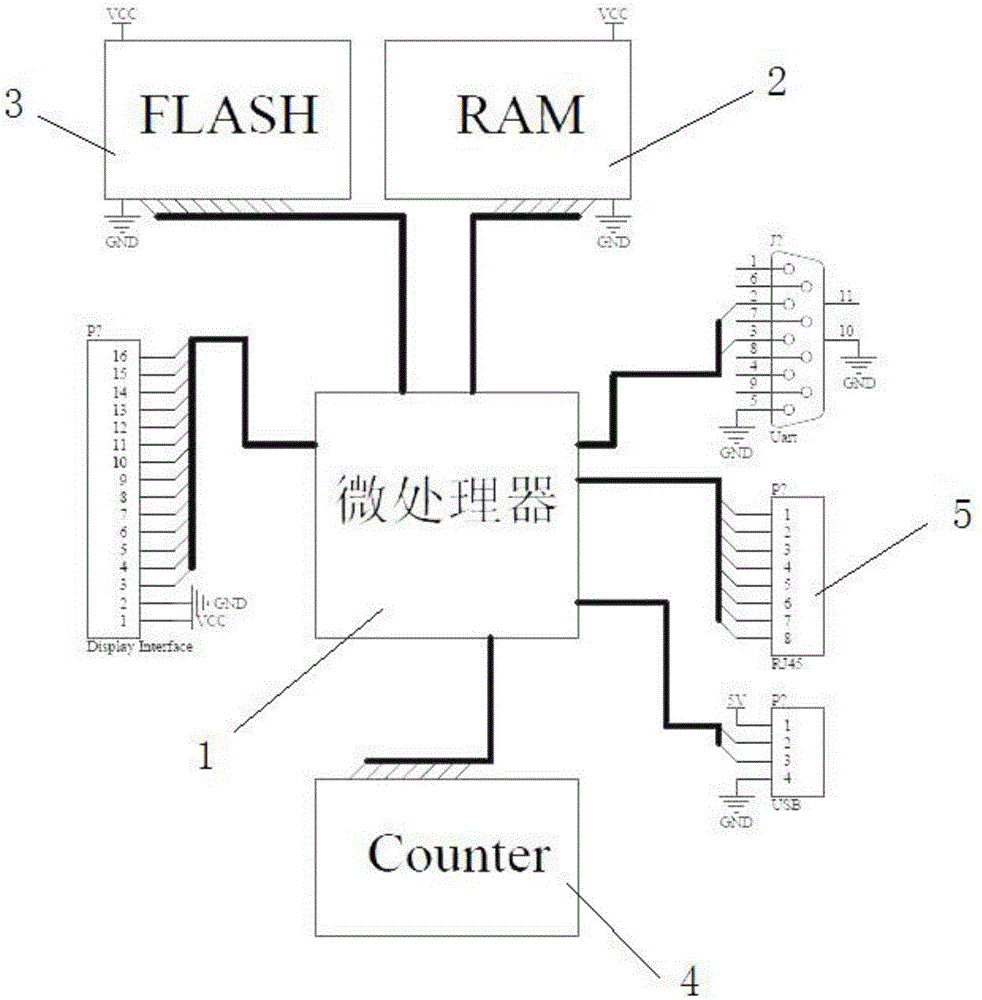

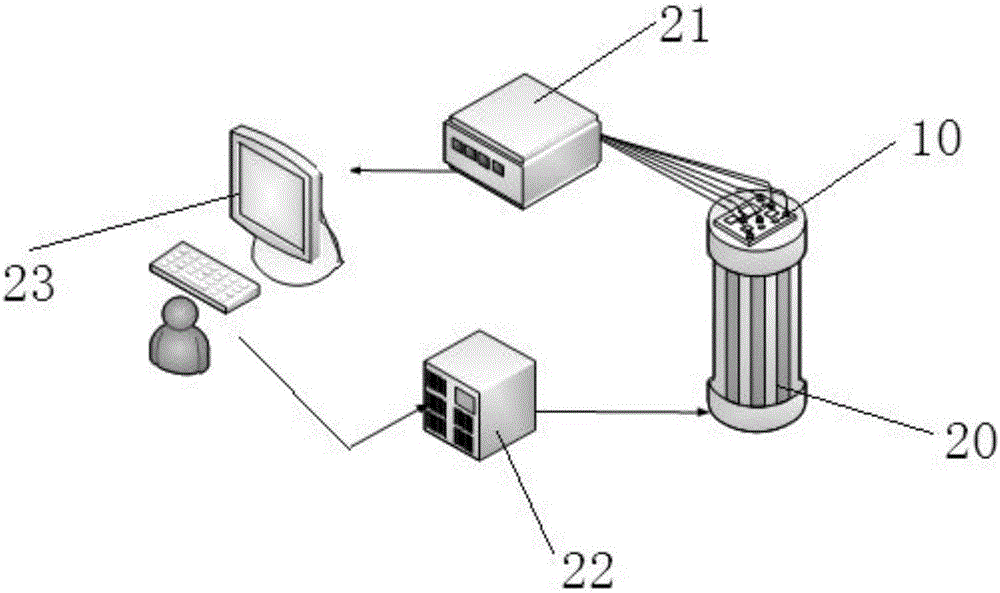

[0092] combine figure 1 The flow chart, the following embodiments include determining the cross power spectral density function algorithm under random vibration conditions, deriving the modal parameter identification algorithm, using the Steinberg model to predict the remaining life of circuit board components, selecting and testing electronic products and online monitoring devices, and generating cross power For the spectral density curve, the first-order resonance frequency and damping ratio are calculated according to the modal parameter identification algorithm and the cross-power sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com