Two-dimensional and three-dimensional integrated imaging measurement system

An imaging measurement and three-dimensional technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of high cost, difficulty, and inability to measure stress and birefringence changes, so as to improve the degree of automation, reduce costs, and improve The effect of measuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

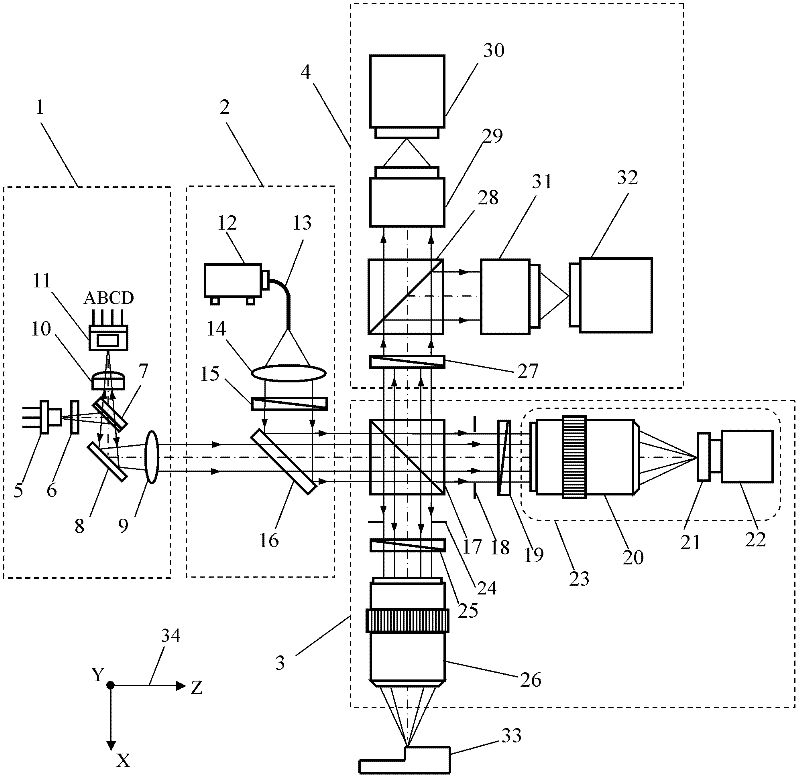

[0033] Such as figure 1 As shown, in the present embodiment, in the astigmatic autofocus unit 1, the red laser light with a center wavelength of 650nm emitted by the semiconductor laser 5 in the astigmatic autofocus unit 1 is reflected on the mirror 8 through the spectroscopic grating 6 and the first spectroscopic mirror 7 in sequence, and then reflected The mirror 8 reflects into the collimating mirror 9 , and the collimating mirror 9 shapes and outputs a parallel red laser beam to enter the light source unit 2 .

[0034] Such as figure 1 As shown, in the light source unit 2, the wide-spectrum white light beam emitted by the halogen lamp 12 passes through the light-guiding optical fiber 13 and then sequentially passes through the light collecting mirror 14, the polarizing plate 15 and the second dichroic lens 16, and the light from the astigmatic auto-focus unit 1 The red laser beams enter the Linnik interferometer 3 together.

[0035] Such as figure 1As shown, in the Linn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com