Plunger Lift Apparatus

a technology of lifting apparatus and plunger, which is applied in the direction of fluid removal, earthwork drilling and mining, and wellbore/well accessories, etc., can solve the problems of sleeve falling back down the production string, loss of fluid load being lifted by the plunger, and opening of the passage, so as to improve the appreciation of the contribution to the art

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

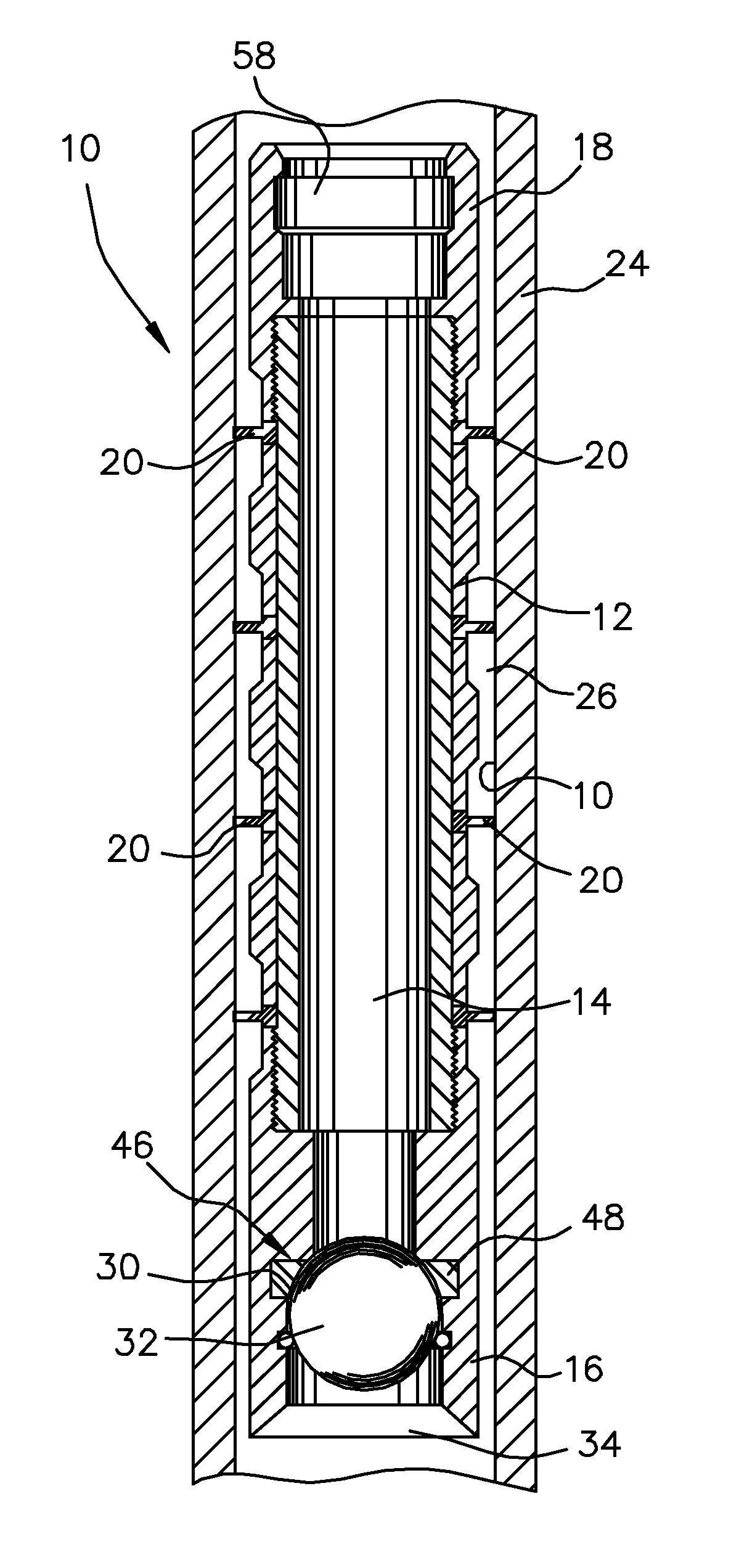

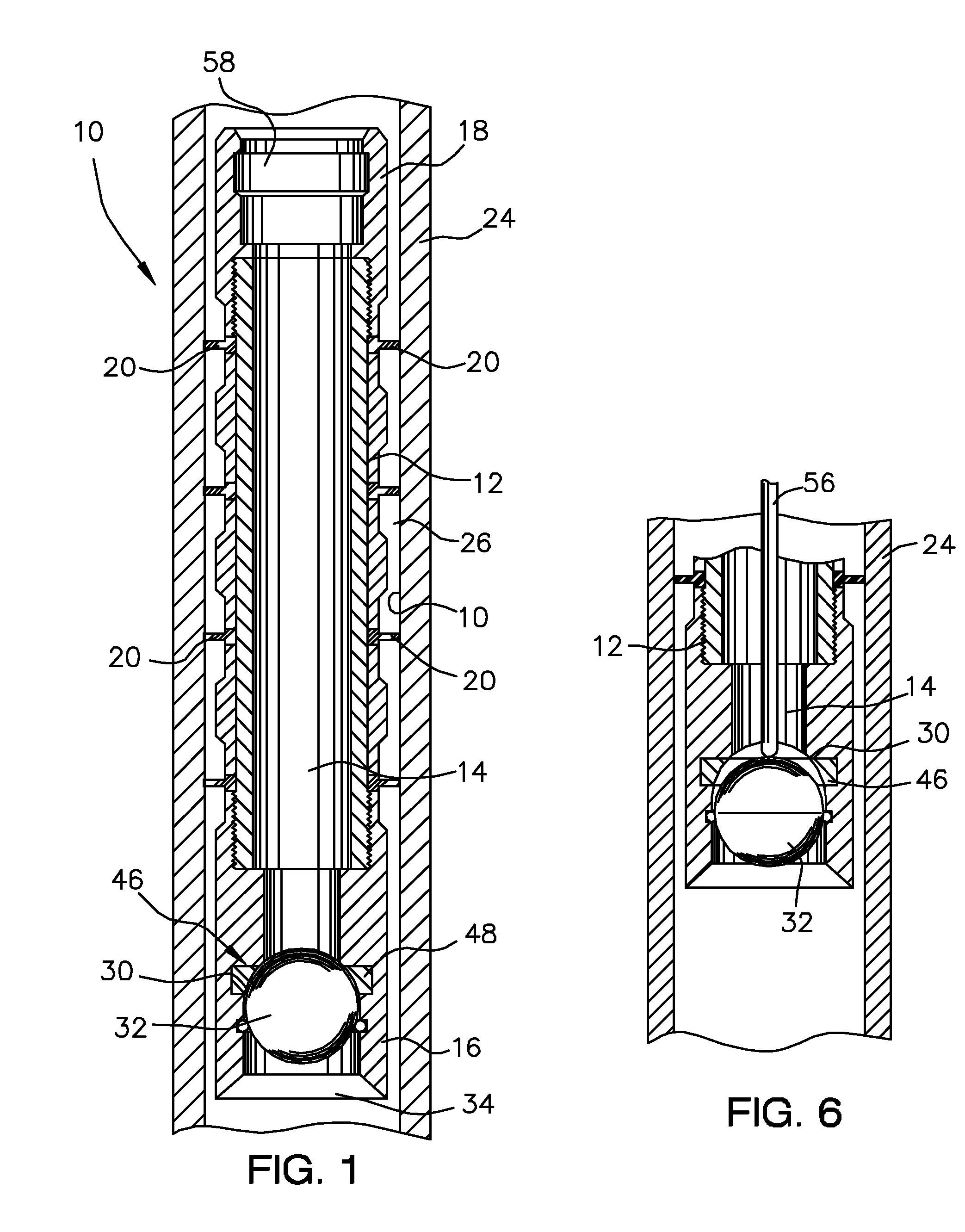

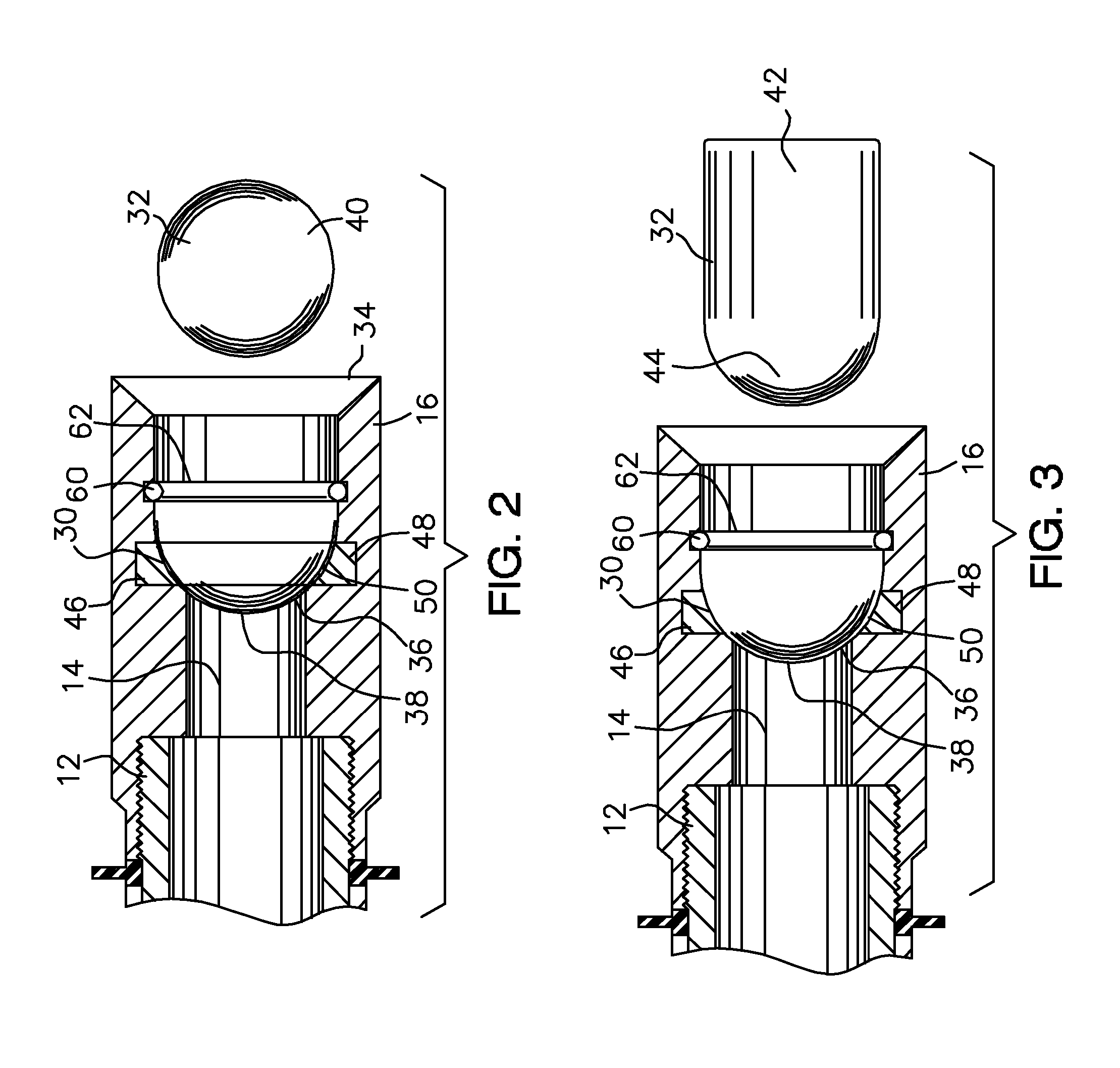

[0021] Referring now to the drawings, the plunger 10 of this invention has an improved construction affording the plunger an increased cycle frequency and cycle efficiency in lifting fluid that has accumulated in a production string of well. The improved construction allows the use of a more dense detachable valve member and a less dense sleeve, as will be further described in detail below.

[0022] With reference now to FIG. 1, the plunger 10 includes a sleeve 12 having a through passage 14 that extends longitudinally through the sleeve from a first, bottom end, 16 to a second, top end 18. The sleeve 12 may comprises several sections coupled together as shown or can be made unitary. The second end 18 can define an internal fishing neck 58.

[0023] The sleeve 12 carries sealing elements 20 which are engagable with the inner surface 22 of a production string 24 sealing the annulus 26 between the sleeve and the inner surface of the production string from fluid flow. However, the sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com