Intelligent Well Control System for Three or More Zones

a well control system and intelligent technology, applied in the field of intelligent well control, can solve the problems of lack of space for nesting shrouds, difficult to have available space, and space-out of multiple seal assemblies with multiple concentric strings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

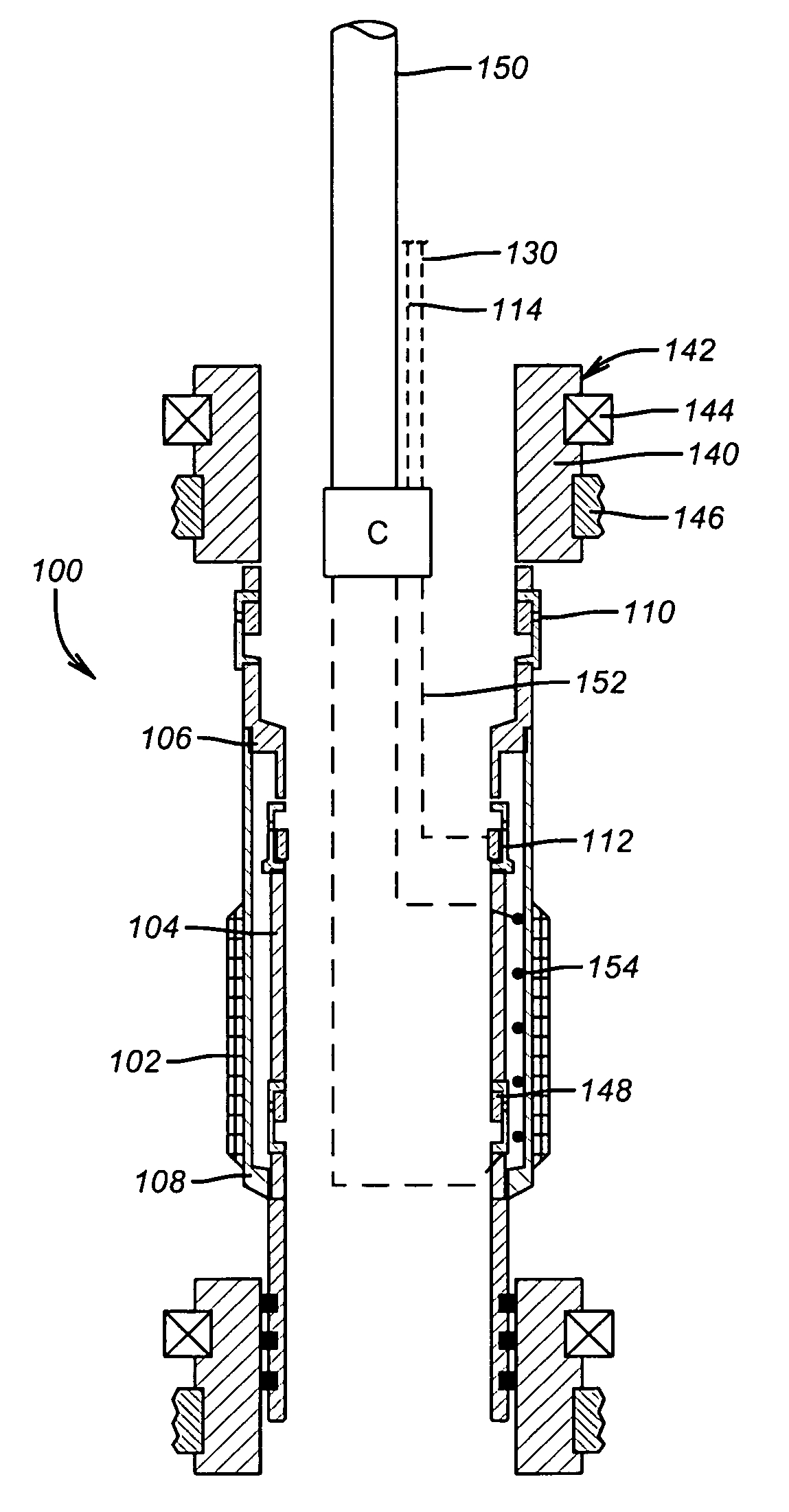

[0014]One module 100 in a screened completion string is illustrated in FIG. 4. The modules 100 can be connected directly to each other across a long producing interval or they can have blank pipe for proper spacing in multiple zones downhole. Each module 100 has at least one screen section 102 and an internal blank pipe 104 that spans the screen 102 and is sealed on opposed ends 106 and 108. There is a gravel exit port with a sliding sleeve to selectively open and close the port 110. The port 110 is offset from the blank pipe 104. A production valve 112 is in blank pipe 104 and the module is pre-piped with control lines 114 better seen in FIG. 5. The hydraulic control lines 114 extend from an upper end 116 to a lower end 118. In one alternative, the radial exit at lower end 118 is between seals 120 and 122. Similarly at opposite end 116 there is a radial exit for the hydraulic lines between seals 124 and 126 of an adjacent blank pipe or other module 128 whose lower end is only shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com