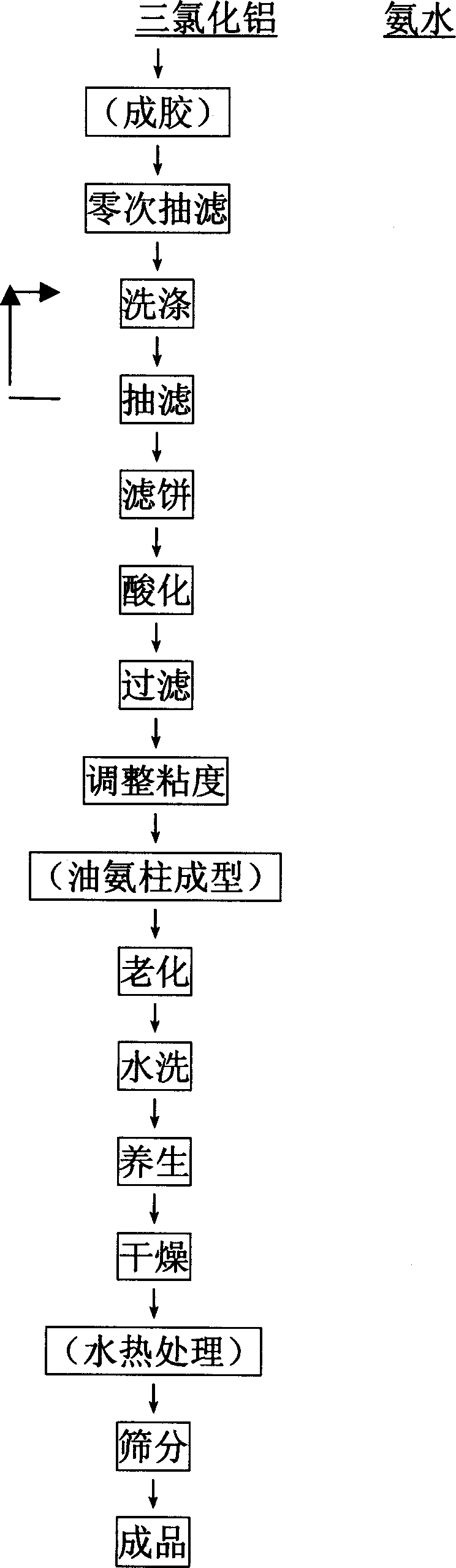

Straight chain paraffin dehydrogenation catalyst carrier production process

A dehydrogenation catalyst, straight-chain alkane technology, applied in the direction of catalyst carrier, physical/chemical process catalyst, alumina/aluminum hydroxide, etc., can solve the problems of large loss of active component platinum, high catalyst price, and more dust, etc. achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation

[0022] (1) Effect of gelling conditions on bulk ratio

[0023] The gelling temperature is low, the colloidal particles are fine, difficult to filter, and the bulk ratio is large. If the temperature is high, the added ammonia is easy to volatilize, making it difficult to maintain a stable pH value during the gelation and washing process, and the smell of ammonia is too large, which is inconvenient to operate. The more suitable gelation temperature is 70°C. See Table 1:

[0024] experiment

[0025] (2) Effect of PH value of gelling on bulk specific gravity

[0026] If the PH value of gelling is too low, the bulk ratio will be large, and if the PH value is too high, the bulk ratio will gradually increase, but slowly, so it is very important to control the PH value during gelling.

[0027]

[0028] (3) Effect of acidification conditions on bulk specific gravity

[0029] Under the same conditions, tests with different conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com