Method for recycling gold and silver from silver separating residues of copper anode slime

A technology for copper anode slime and silver-separating slag, which is applied in the direction of improving process efficiency, can solve the problems of not considering environmental protection, environmental pollution, waste of valuable metals, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

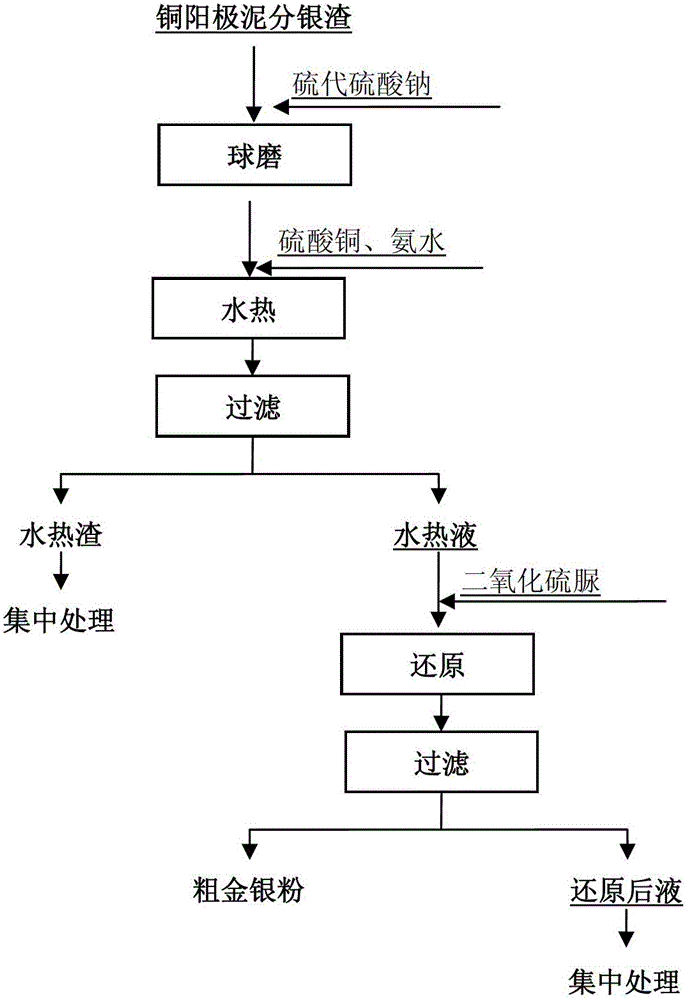

Image

Examples

Embodiment 1

[0020] The silver slag and sodium thiosulfate of the copper anode slime are mixed and ball milled, wherein the mass ratio of the silver slag and sodium thiosulfate of the copper anode slime is 10:1, and the ball milling time is 1 hour to obtain a ball mill; The material and the reaction solvent are loaded into the hydrothermal reaction kettle, wherein the mass ratio of the ball mill material and the reaction solvent is 1:1, the total volume of the ball mill material and the reaction solvent accounts for 20% of the volume of the hydrothermal reaction kettle, and the hydrothermal reaction temperature is 140°C , the reaction time is 1 hour, wherein the reaction solvent is composed of copper sulfate and aqueous ammonia solution, the concentration of copper sulfate is 3g / L, and the concentration of 20% ammonia water is 50mL / L (20% ammonia water); the hydrothermal product is filtered to obtain hydrothermal slag and Hydrothermal liquid, hydrothermal slag centralized treatment; add thi...

Embodiment 2

[0022] The silver slag of copper anode slime and sodium thiosulfate are mixed and ball milled, wherein the mass ratio of silver slag and sodium thiosulfate of copper anode slime is 10:3, and the ball milling time is 2 hours to obtain ball mill; ball mill The material and the reaction solvent are loaded into the hydrothermal reaction kettle, wherein the mass ratio of the ball mill material and the reaction solvent is 1:1.5, the total volume of the ball mill material and the reaction solvent accounts for 25% of the volume of the hydrothermal reaction kettle, and the hydrothermal reaction temperature is 180°C , the reaction time is 4 hours, wherein the reaction solvent is composed of copper sulfate and aqueous ammonia solution, the concentration of copper sulfate is 8g / L, and the concentration of 20% ammonia water is 100mL / L (20% ammonia water); the hydrothermal product is filtered to obtain hydrothermal slag and Hydrothermal liquid, hydrothermal slag centralized treatment; add th...

Embodiment 3

[0024] The silver slag and sodium thiosulfate of the copper anode slime are mixed and ball milled, wherein the mass ratio of the silver slag and sodium thiosulfate of the copper anode slime is 10:2, and the ball milling time is 1.5 hours to obtain a ball mill; The material and the reaction solvent are loaded into the hydrothermal reaction kettle, wherein the mass ratio of the ball mill and the reaction solvent is 1:3, the total volume of the ball mill and the reaction solvent accounts for 40% of the volume of the hydrothermal reaction kettle, and the hydrothermal reaction temperature is 160°C , the reaction time is 2 hours, wherein the reaction solvent is composed of copper sulfate and aqueous ammonia solution, the concentration of copper sulfate is 5g / L, and the concentration of 20% ammonia water is 70mL / L (20% ammonia water); the hydrothermal product is filtered to obtain hydrothermal slag and Hydrothermal liquid, hydrothermal slag centralized treatment; Add thiourea dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com