Chlorine-resistant anti-pollution nanofiltration membrane for soft water and preparation method thereof

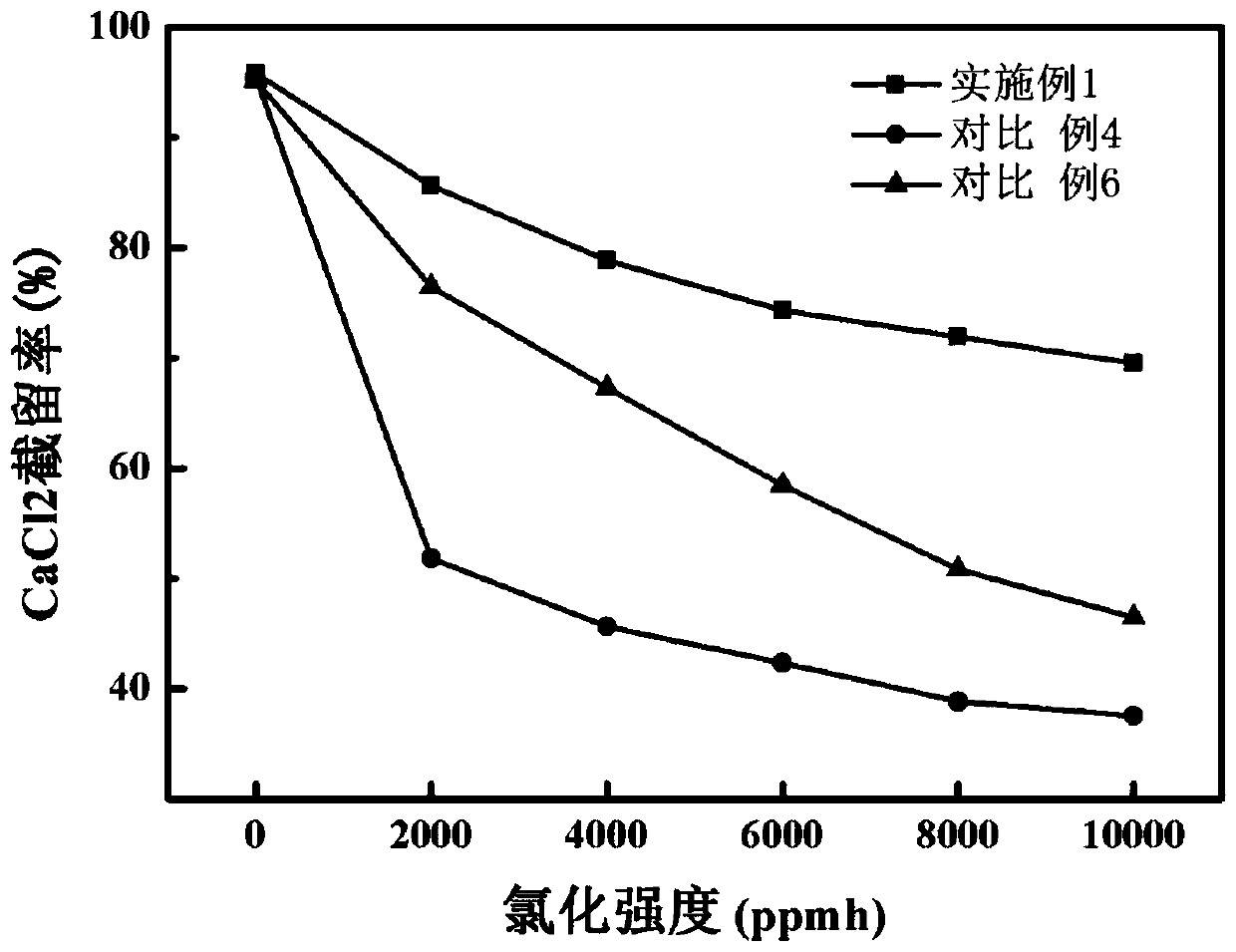

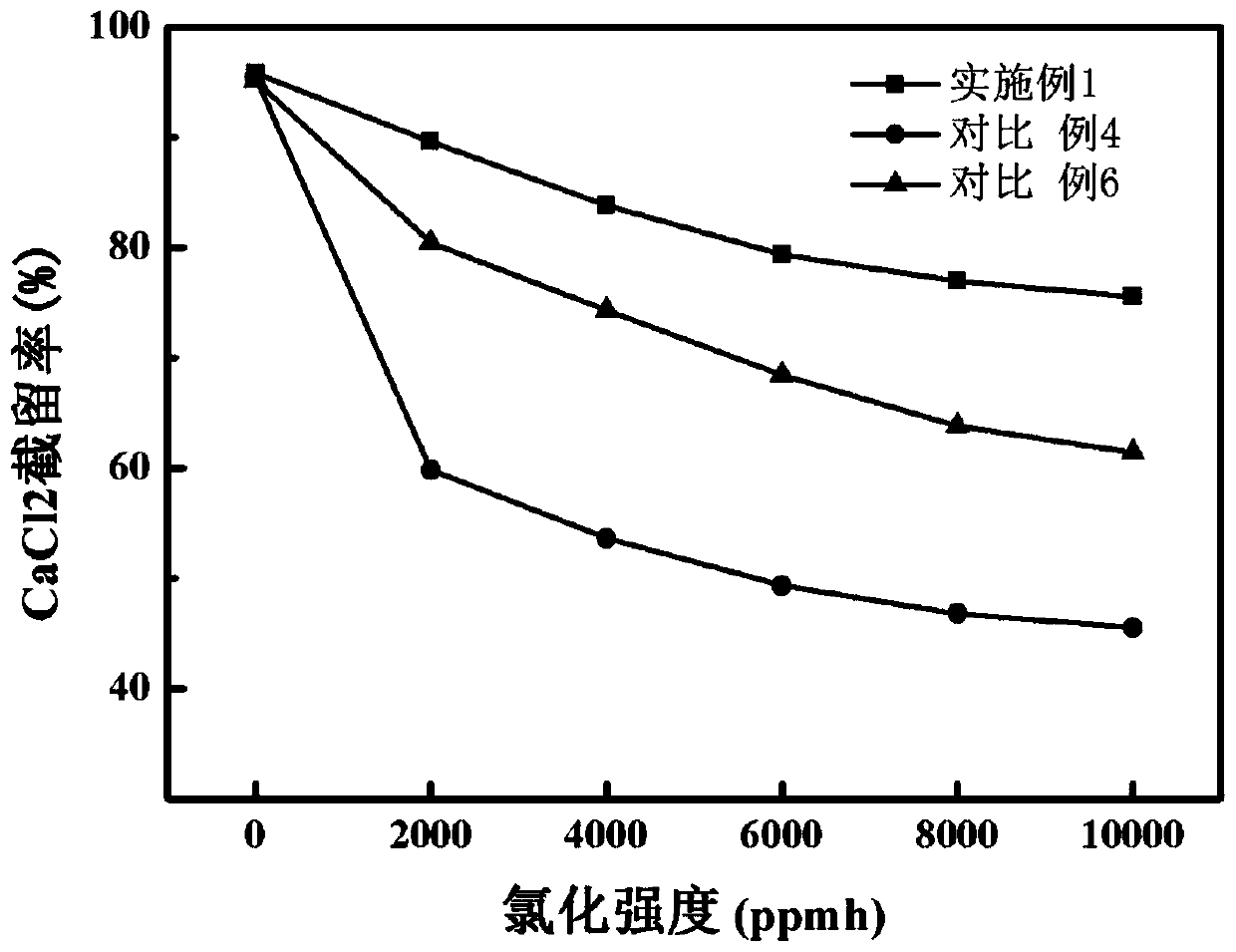

An anti-pollution, nanofiltration membrane technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Pollution performance and other issues, to achieve the effect of chlorine resistance and anti-pollution performance improvement, excellent chlorine resistance and anti-pollution performance, and excellent hardness removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Preparation of polysulfone-based membrane: 18wt% polysulfone and 1.0wt% copovidone VA64 were dissolved in N,N-dimethylformamide to prepare a casting solution, and then the casting solution was scraped on On a polyester non-woven fabric with a thickness of 150 μm, immersed in a 25°C water bath for 30 seconds to form a phase inversion film, take it out to obtain a polysulfone-based film;

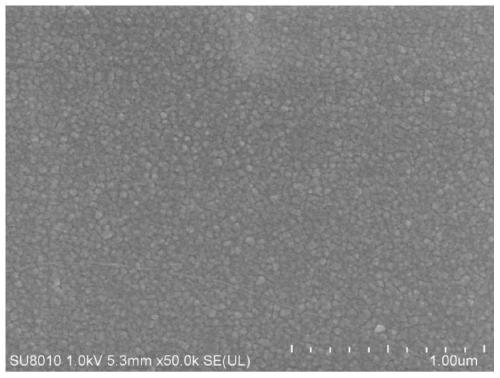

[0063] (2) Preparation of polypiperazine amide layer: the polysulfone base membrane obtained in step (1) is fixed, and the prepared aqueous solution containing 1.5wt% PIP and 2.0wt% trisodium phosphate is poured on the surface of the base membrane, The basement membrane is completely immersed in the aqueous phase solution, immersed for 2min at room temperature, and the residual solution on the surface of the basement membrane is removed after pouring off the aqueous phase solution, and then the prepared Isopar G oil phase solution containing 0.15wt% TMC is poured on the membrane surf...

Embodiment 2

[0066] The main difference between this example and Example 1 is that the co-polyvidone VA64 concentration in the casting solution in the step (1) is 0.5wt%.

Embodiment 3

[0068] The main difference between this example and Example 1 is that the co-polyvidone VA64 concentration in the casting solution in the step (1) is 5.0 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com