Fabric reductive cleaning agent with high soaping-resistant color fastness and high sublimation fastness, preparation method thereof and polyester fabric treatment method

A technology for polyester fabrics and treatment methods, which is applied in the direction of chemical instruments and methods, fiber treatment, detergent compositions, etc., and can solve the problem of poor soaping fastness and sublimation fastness of polyester fabrics, and poor washing resistance of three-proof functions Stable, floating color is not clean and other problems, to achieve the effect of high color fastness to sublimation, stable quality, high color fastness to soaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The base fabric is made of polyester fiber.

[0027] Step (1): Perform alkaline reduction washing after dyeing. The components of the reducing cleaning agent are: 1 g of caustic soda with a concentration of 30%, 0.5 g of thiourea dioxide, 0.5 g of ethylene oxide condensate, and 0.5 g L of sodium alkylsulfonate according to the mass added in per liter of water. After dyeing with a high-temperature and high-pressure machine, remove the dyeing residue, and then add an alkaline reduction cleaning agent at a ratio of 10:1 to the mass ratio of the alkaline reduction cleaning agent to the fabric, perform alkaline reduction washing at a temperature of 95°C for 28 minutes, and then wash with water. The temperature is 115 ℃ cylinder drying out cylinder.

[0028] Step (2): Three anti-heat setting finishing. The components of the three-proof heat-setting finishing agent are: 60 g of fluorocarbon resin water repellent, 5 g of block amino silicone oil, and 5 g of isocyanate, based ...

Embodiment 2-7

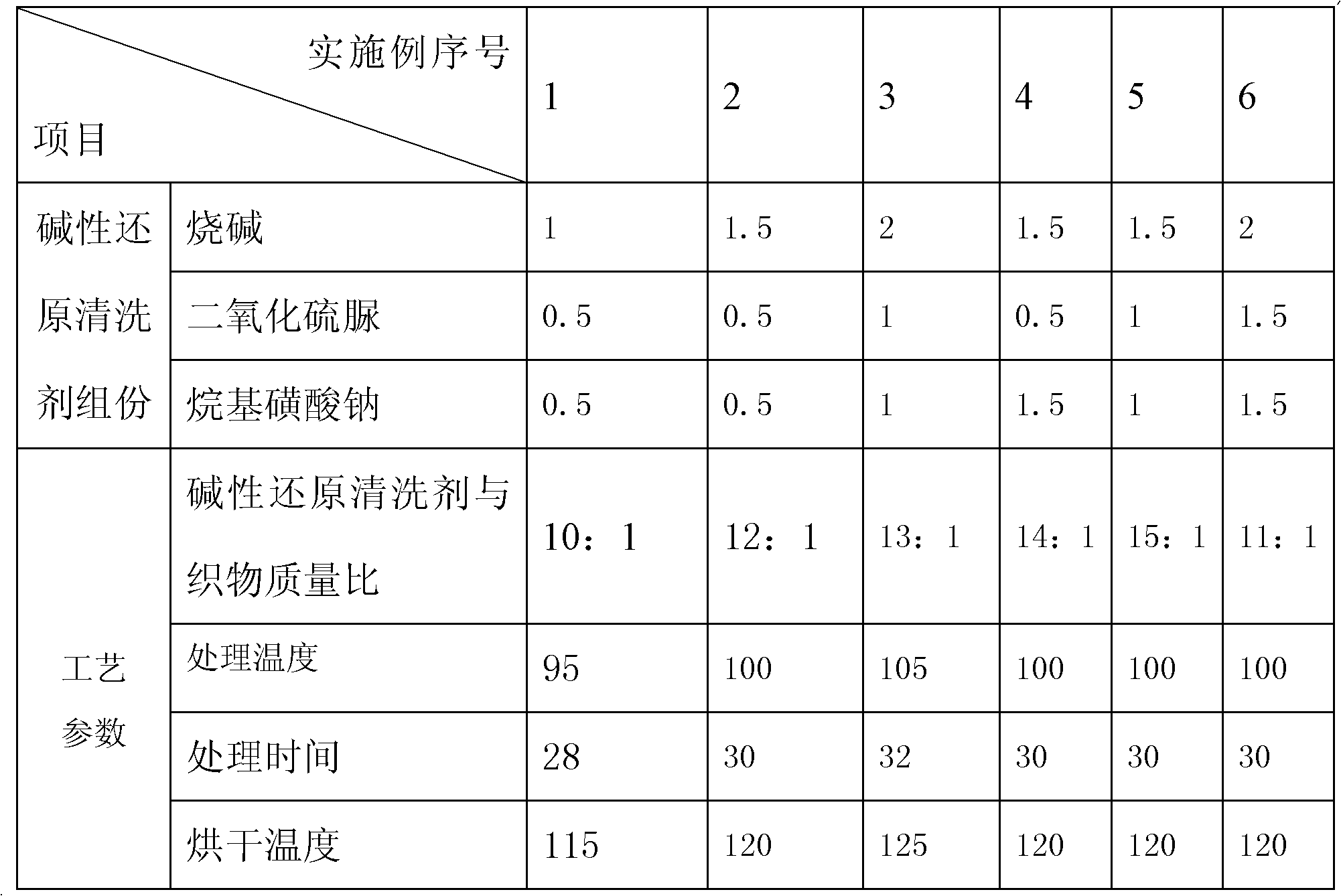

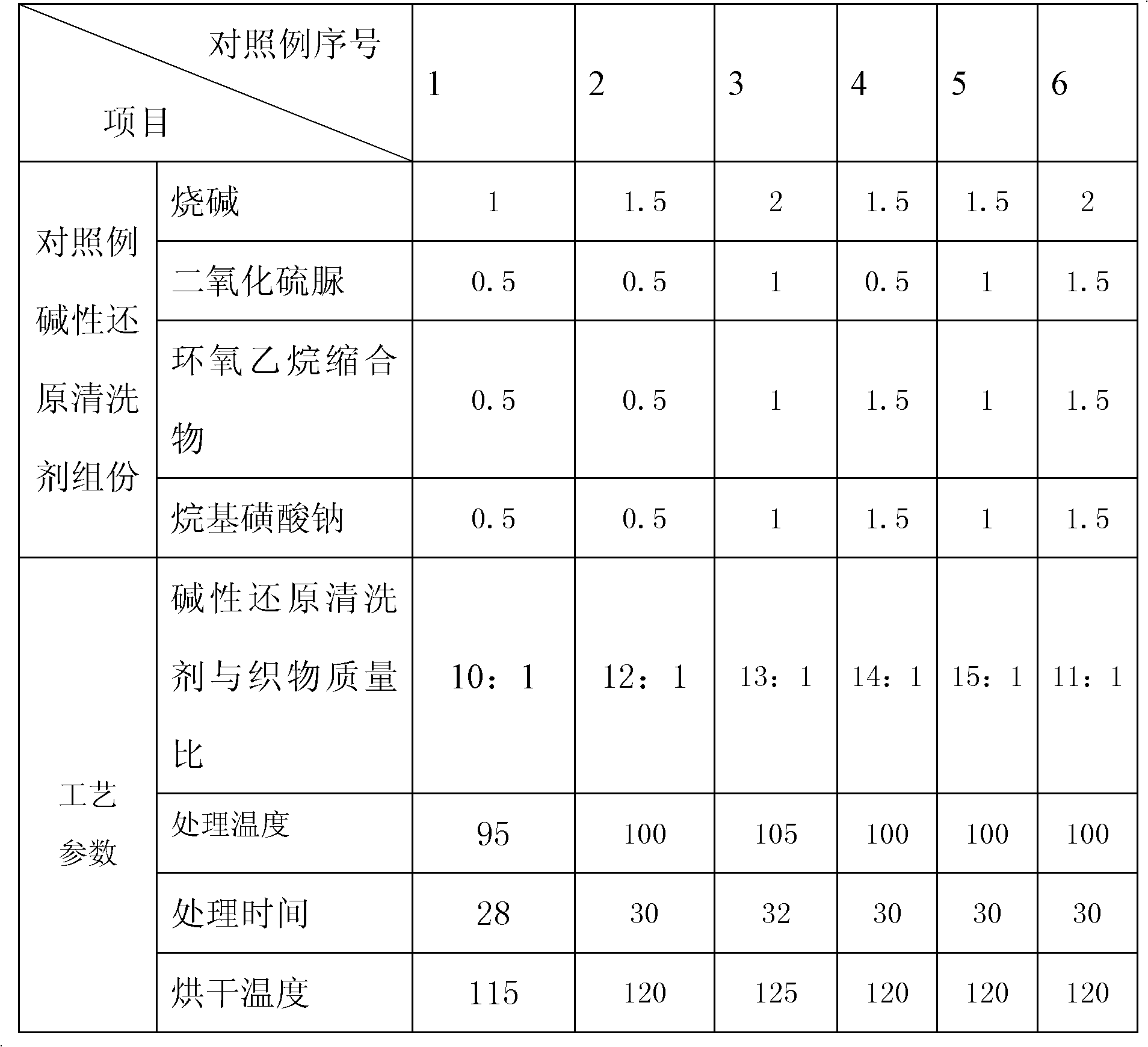

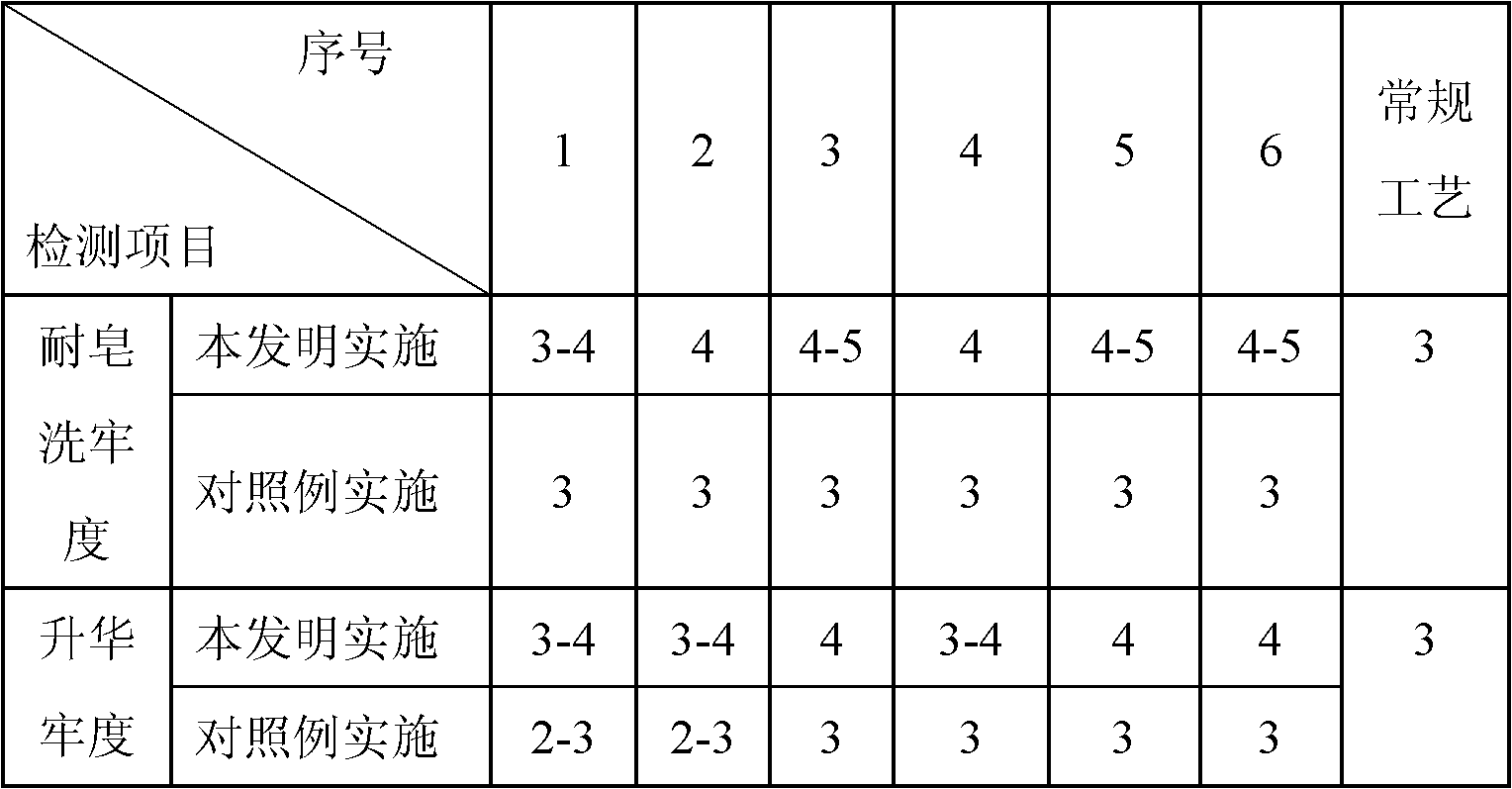

[0034] See Table 1 for the components of the reduction cleaning agent and the parameters of the reduction cleaning process, and Table 2 for the components of the three-proof heat setting finishing agent and the parameters of the three-proof heat setting finishing process. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com