Compound corrosion inhibitor with corrosion inhibiting effect as well as preparation method and application of compound corrosion inhibitor

A corrosion-inhibiting, corrosion-inhibiting agent technology, applied in wellbore/well components, earthwork drilling, organic chemistry, etc., can solve problems such as easy pollution to the environment, poor corrosion inhibition effect, poor water solubility, etc., to achieve No emulsification tendency, low cost, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

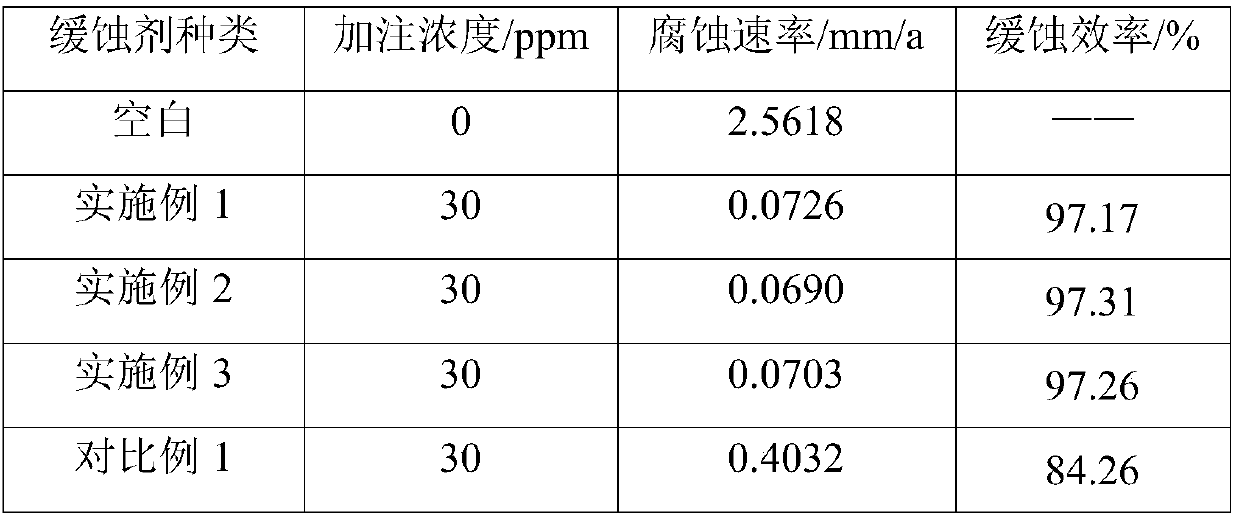

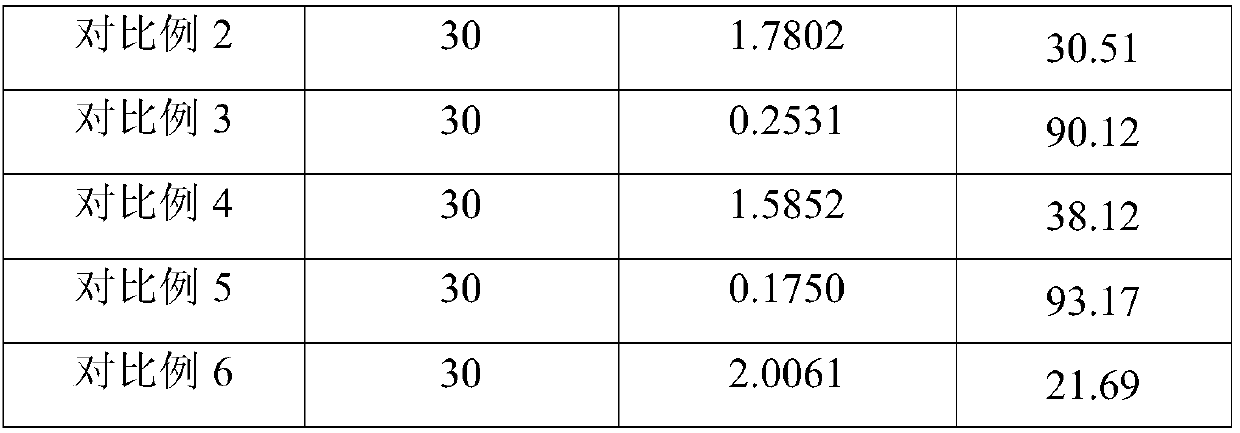

Embodiment 1

[0031] Add 10g of tall oleic acid imidazoline quaternary ammonium salt, 50g of isopropanol, heat up to 60°C and keep stirring, mix well and add 30g of fatty alcohol polyoxyethylene ether (AEO-3) (Jiangsu Haian Petrochemical Factory), 5g of thiourea dioxide and 5g of sodium pyrophosphate were stirred for 1 hour at a constant temperature until the solution was uniform, and the compound corrosion inhibitor of this embodiment for inhibiting corrosion was obtained.

Embodiment 2

[0033] Add 30g tall oleic acid imidazoline quaternary ammonium salt, glycerol 15g, heat up to 60°C and keep stirring, mix well and add 20g fatty alcohol polyoxyethylene ether (AEO-3), 30g water, 2g thiourea dioxide, 3g Sodium pyrophosphate, continue to stir for 1.5 hours under constant temperature conditions, until the solution is uniform, that is, the composite corrosion inhibitor of this embodiment for inhibiting corrosion is obtained.

Embodiment 3

[0035] Add 50g of tall oleic acid imidazoline quaternary ammonium salt, 35g of isopropanol, heat up to 60°C and keep stirring, mix well and add 10g of fatty alcohol polyoxyethylene ether phosphate (AEO-3P), 3g of thiourea dioxide, 2g of coke Sodium phosphate, continue to stir for 1.5 hours under constant temperature conditions, until the solution is uniform, that is, the composite corrosion inhibitor of this embodiment for inhibiting corrosion is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com