Method for preparing nano metallic nickel in spent electroless nickel plating solution

A technology of electroless nickel plating and nano-metal, which is applied in the direction of improving process efficiency, etc., can solve the problems of reaction condition requirements, large equipment investment, skin and mucous membrane corrosion, etc., and achieve the effect of low reaction conditions, less investment, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

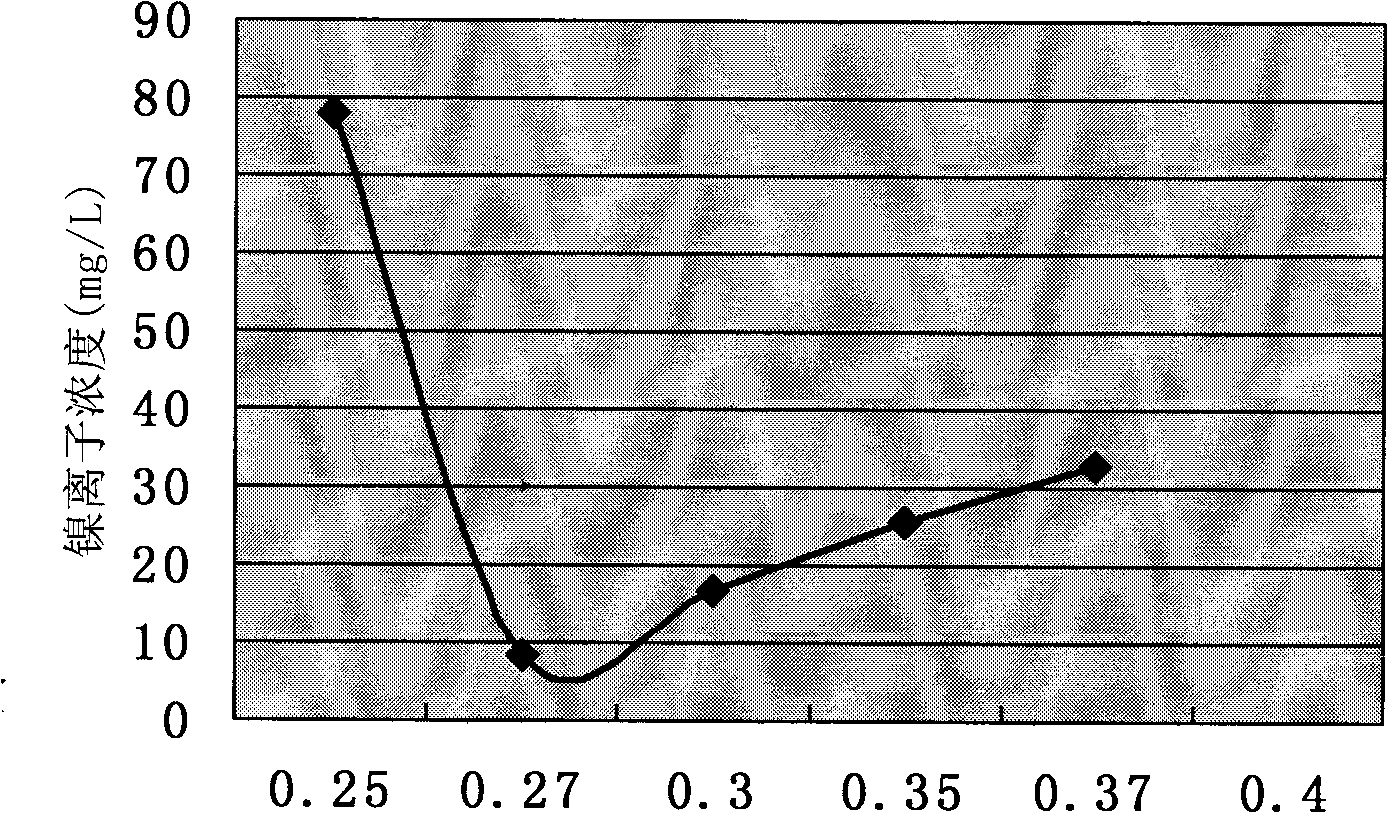

[0011] First, add 0.20 gram-0.30 gram of reducing agent thiourea dioxide in every 100 milliliters of electroless nickel plating waste liquid, (the addition content of this reducing agent should not be too much, experiment proves that when content is too much, the thiourea in electroless nickel plating waste liquid The concentration of nickel ions will increase instead, see table 1 below)

[0012]

[0013] Thiourea dioxide (g)

[0014] Table 1

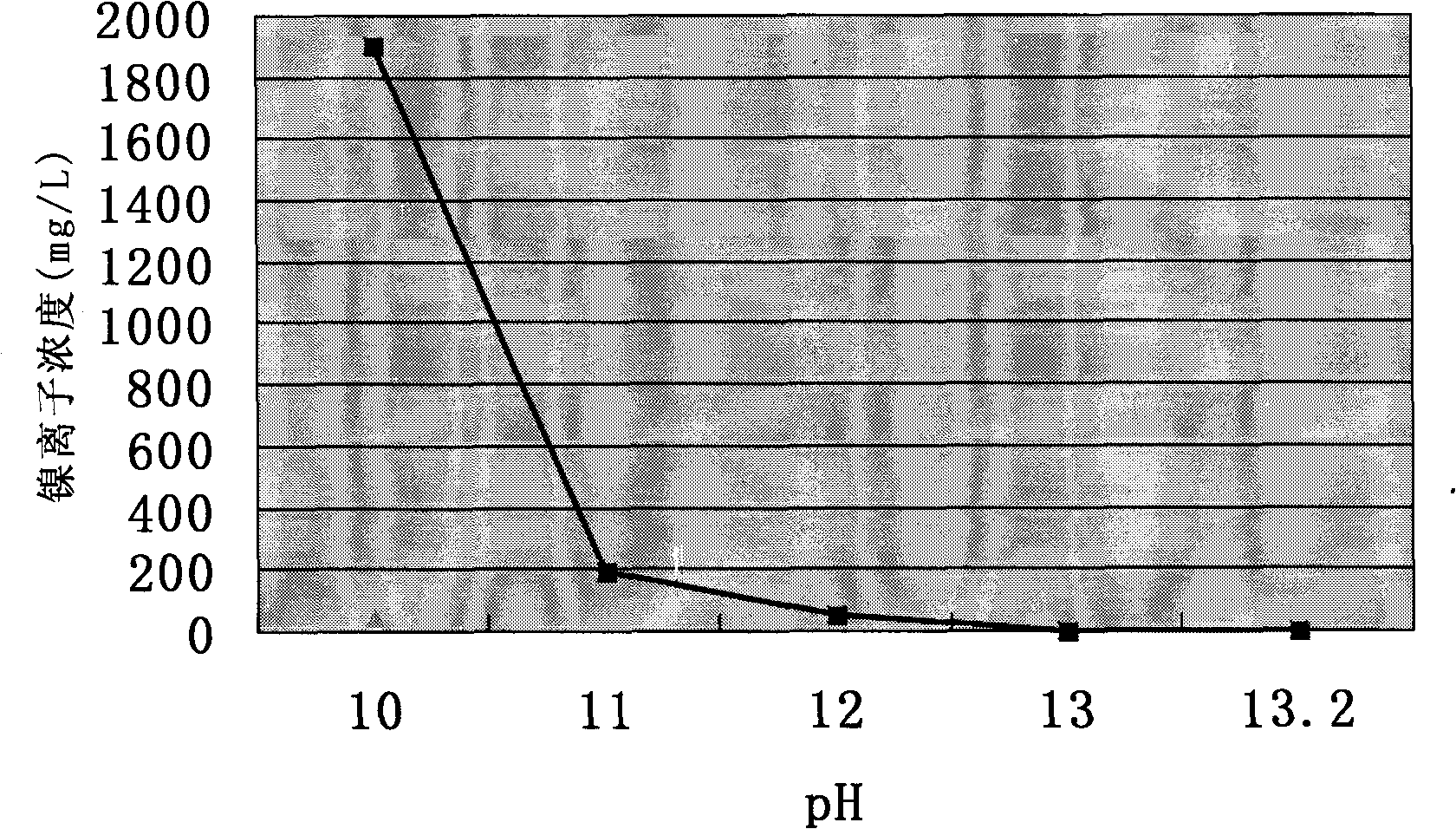

[0015] Then borrow 3 gram-7 gram sodium hydroxide to adjust described electroless nickel plating waste liquid to alkalescence, (experimental data shows, alkalescence is bigger, the nickel ion concentration in electroless nickel plating waste liquid is lower, see table 2 below )

[0016]

[0017] Table 2

[0018] At the same time, heat the electroless nickel plating waste solution to 70°C-100°C, and react at a constant temperature for 5 minutes to 20 minutes. At this time, cool down to 10°C-30°C, filter the electroless nickel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com