Colloidal emulsion explosive for high-detonation-velocity deepwater blasting and preparation method of colloidal emulsion explosive

An emulsion explosive and high detonation velocity technology, applied in the field of explosives, can solve the problems of poor reliability of charging and initiation network settings, difficult blasting operations, and divers can only focus on it, so as to improve explosive performance and storage performance, and reduce production costs. Effect of sensitization blending time and excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

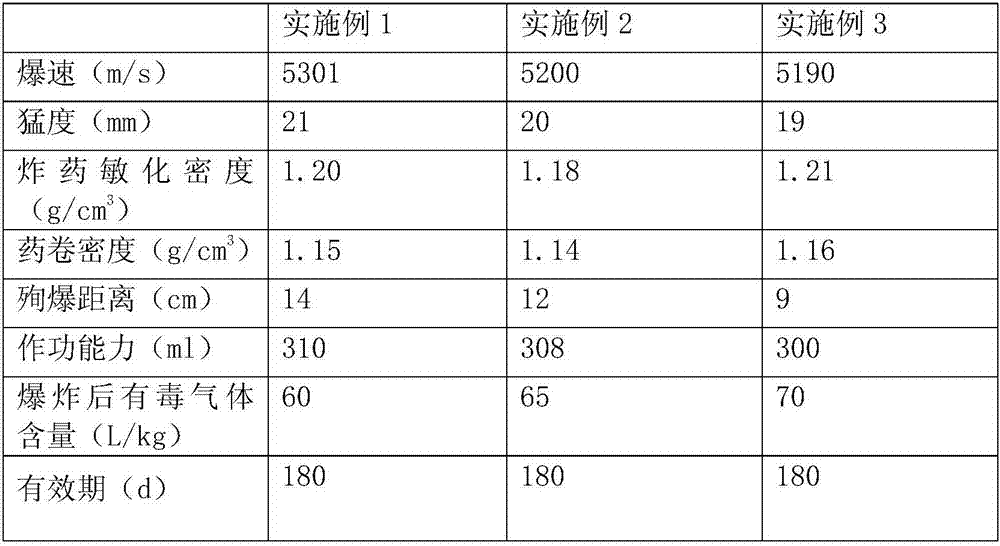

Embodiment 1

[0036] This embodiment provides a colloidal emulsion explosive for high detonation velocity deep water blasting. The colloidal emulsion explosive for high detonation velocity deep water blasting includes the following components in parts by mass:

[0037] Main oxidant: 30 parts, auxiliary oxidant: 10 parts, reducing agent: 5 parts, water: 10 parts, additive: 0.5 parts, emulsifier: 3 parts, sensitizer: 5 parts, density regulator: 0.5 parts, crystal shape modification Stabilizing agent: 1 part, stabilizer: 0.1 part; foaming agent: 4 parts, sensitizing additive: 1 part, flame suppressant: 4 parts, adhesive: 2 parts;

[0038] The main oxidant comprises the following components by weight percentage: iron nitrate: 20%, zinc nitrate: 15%, sodium nitrate: 10%, the balance is ammonium nitrate, and the sum of the above components is 100%;

[0039] The auxiliary oxidant is sodium nitrate; the reducing agent is paraffin; the additive is ammonium perchlorate; the emulsifier is a nonionic s...

Embodiment 2

[0049] This embodiment provides a colloidal emulsion explosive for high detonation velocity deep water blasting. The colloidal emulsion explosive for high detonation velocity deep water blasting includes the following components in parts by mass:

[0050] Main oxidant: 40 parts, auxiliary oxidant: 15 parts, reducing agent: 9 parts, water: 20 parts, additive: 1.5 parts, emulsifier: 5 parts, sensitizer: 7 parts, density regulator: 1 part, crystal shape modification Stabilizing agent: 2 parts, stabilizer: 0.5 parts; foaming agent: 7 parts, sensitizing additive: 3 parts, flame suppressant: 6 parts, adhesive: 4 parts;

[0051] The main oxidant comprises the following components by weight percentage: iron nitrate: 30%, zinc nitrate: 18%, sodium nitrate: 15%, the balance is ammonium nitrate, and the sum of the above components is 100%;

[0052] The auxiliary oxidant is sodium nitrate; the reducing agent is paraffin; the additive is ammonium perchlorate; the emulsifier is a nonionic s...

Embodiment 3

[0062] This embodiment provides a colloidal emulsion explosive for high detonation velocity deep water blasting. The colloidal emulsion explosive for high detonation velocity deep water blasting includes the following components in parts by mass:

[0063] Main oxidant: 35 parts, auxiliary oxidant: 13 parts, reducing agent: 7 parts, water: 15 parts, additives: 0.8 parts, emulsifier: 4 parts, sensitizer: 6 parts, density regulator: 0.8 parts, crystal shape modification Stabilizing agent: 1.5 parts, stabilizer: 0.3 parts; foaming agent: 5 parts, sensitizing additive: 2 parts, flame suppressant: 5 parts, adhesive: 3 parts;

[0064] The main oxidant comprises the following components by weight percentage: iron nitrate: 25%, zinc nitrate: 17%, sodium nitrate: 13%, the balance is ammonium nitrate, and the sum of the above components is 100%;

[0065] The auxiliary oxidant is sodium nitrate; the reducing agent is paraffin; the additive is ammonium perchlorate; the emulsifier is a noni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com