Preparation method of Fe-C-TiO2 nano tube array

A Nanotube Array, Titanium Oxide Nanotube Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Polish the surface of the Ti base material, clean it and set aside;

[0036] (2) Organic electrolyte preparation:

[0037] Measure 1.47mL of 40% hydrofluoric acid (HF) solution by mass, mix it evenly with 28.53mL of anhydrous dimethyl sulfoxide (DMSO), and prepare a DMSO solution with 2% by mass of HF ;

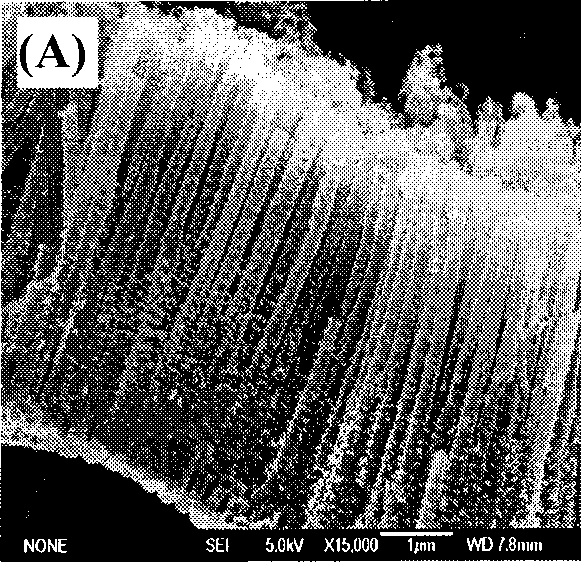

[0038] (3) Preparation of titanium oxide nanotube arrays:

[0039] Using a titanium sheet (1*4cm) with a purity of more than 99.9% as the anode and a platinum sheet (1*2cm) as the cathode, electrolyze for 2 hours at a DC voltage of 45V to produce a titanium oxide nanotube with a length of 5 microns; The amorphous titanium oxide nanotube array prepared above was calcined under aerobic condition at 450° C. for 5 h to crystallize it.

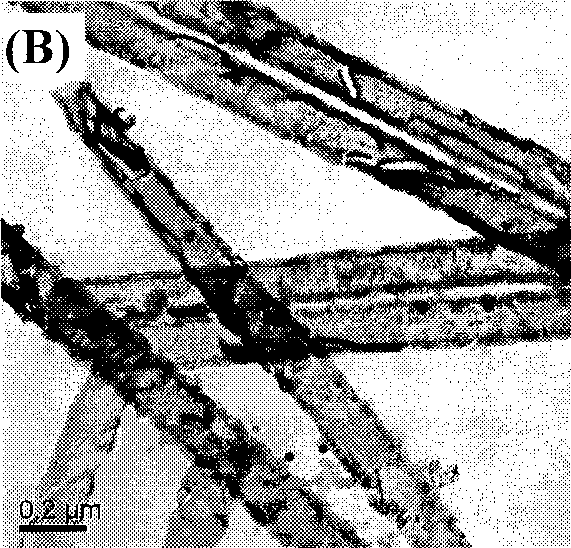

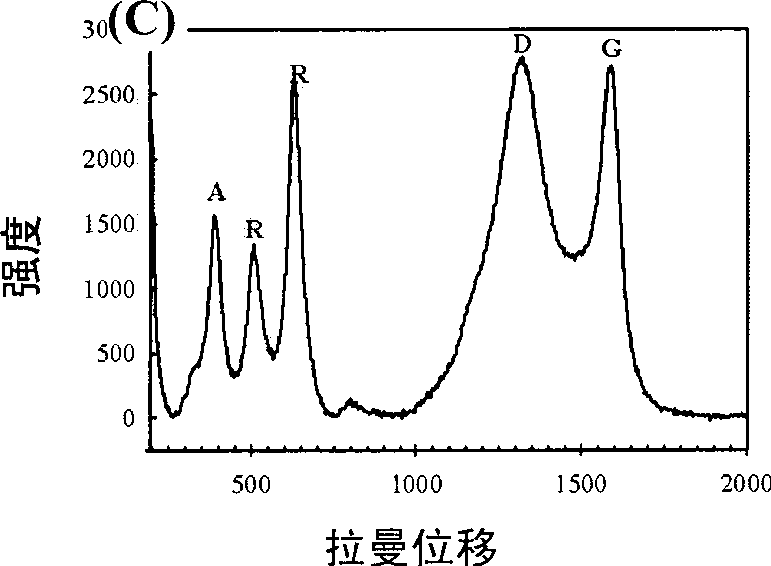

[0040] (4) C-TiO 2 Preparation of composite nanotube arrays:

[0041] With step (3) gained TiO 2 The nanotube array was placed in a graphite tank in an oxygen-free vacuum system, 0.2 g of polyethylene glycol was added as a carbon ...

Embodiment 2

[0045] (1) Polish the surface of the Ti base material, clean it and set aside;

[0046] (2) Organic electrolyte preparation:

[0047] Measure 2.21mL of hydrofluoric acid (HF) solution with a mass percentage of 40%, and mix it with 27.79mL of anhydrous dimethyl sulfoxide (DMSO) to prepare a DMSO solution with a mass percentage of HF of 3%. ;

[0048] (3) Preparation of titanium oxide nanotube arrays: using a titanium sheet (1*4cm) with a purity of more than 99.9% as an anode and a platinum sheet (1*2cm) as a cathode, electrolyze it for 1 hour at a DC voltage of 60V to obtain Nanotubes 12 microns long. The titania nanotube array prepared above was calcined at 500° C. under aerobic conditions for 6 h to crystallize it.

[0049] (4) C-TiO 2 Preparation of composite nanotube arrays:

[0050] With step (3) gained TiO 2 The nanotube array was placed in a graphite tank in an oxygen-free vacuum system, 0.4 g of polyethylene glycol was added as a carbon source, heated to 600° C. u...

Embodiment 3

[0054] (1) Polish the surface of the Ti base material, clean it and set aside;

[0055] (2) Preparation of organic electrolyte:

[0056] Measure 0.375mL of 40% hydrofluoric acid (HF) solution by mass, mix it evenly with 29.625mL of anhydrous dimethyl sulfoxide (DMSO), and prepare a DMSO solution with 0.5% by mass of HF ;

[0057] (3) Preparation of titanium oxide nanotube arrays: use a titanium sheet (1*4cm) with a purity of more than 99.9% as an anode, and a platinum sheet (1*2cm) as a cathode, and electrolyze it for 4 hours at a DC voltage of 35V to obtain Nanotubes 2 microns long. The amorphous titania nanotube arrays prepared above were calcined under aerobic conditions at 400 °C for 4 h to crystallize them.

[0058] (4) C-TiO 2 Preparation of composite nanotube arrays:

[0059] With step (3) gained TiO 2 The nanotube array is placed in a graphite tank in an oxygen-free vacuum system, 0.05 g of polyethylene glycol is added as a carbon source, heated to 500° C. under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com