Preparation method of Mn doped lanthanum titanate photocatalyst fluorescent powder and application

A photocatalyst and phosphor technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of insignificant catalytic effect, low powder purity, fluorescence The problem of low brightness of powder, etc., achieves the effect of promoting the process of environmental pollution control and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

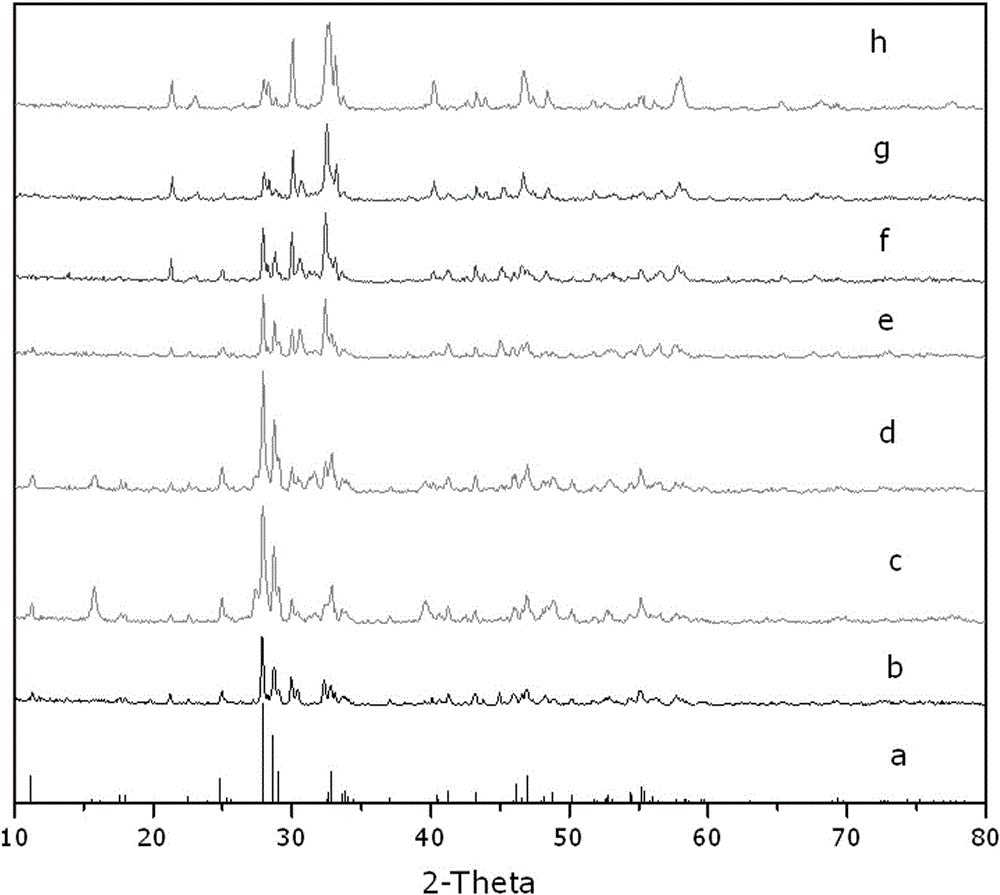

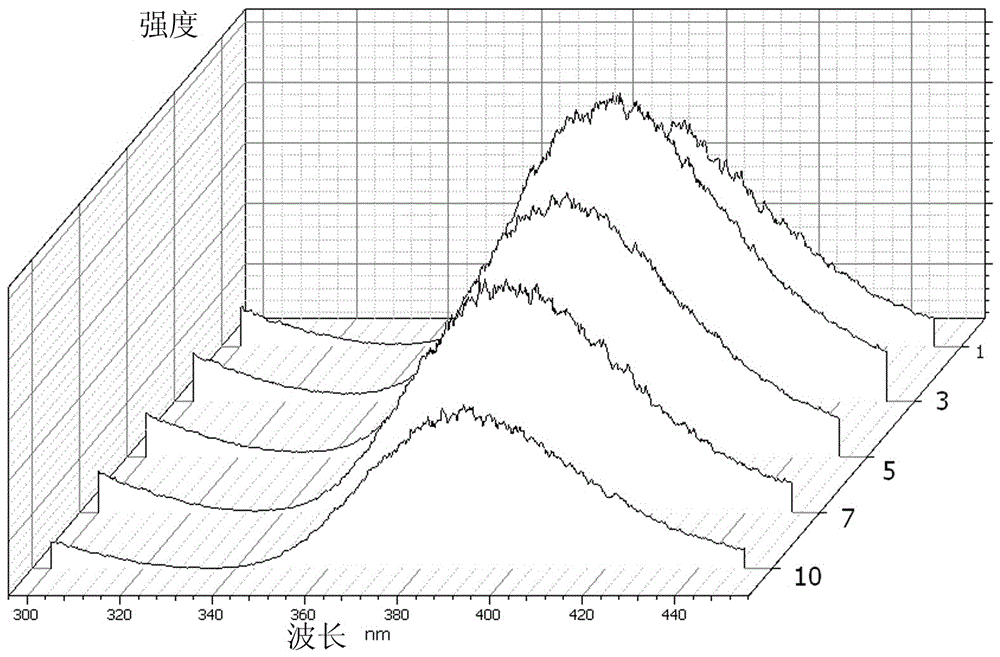

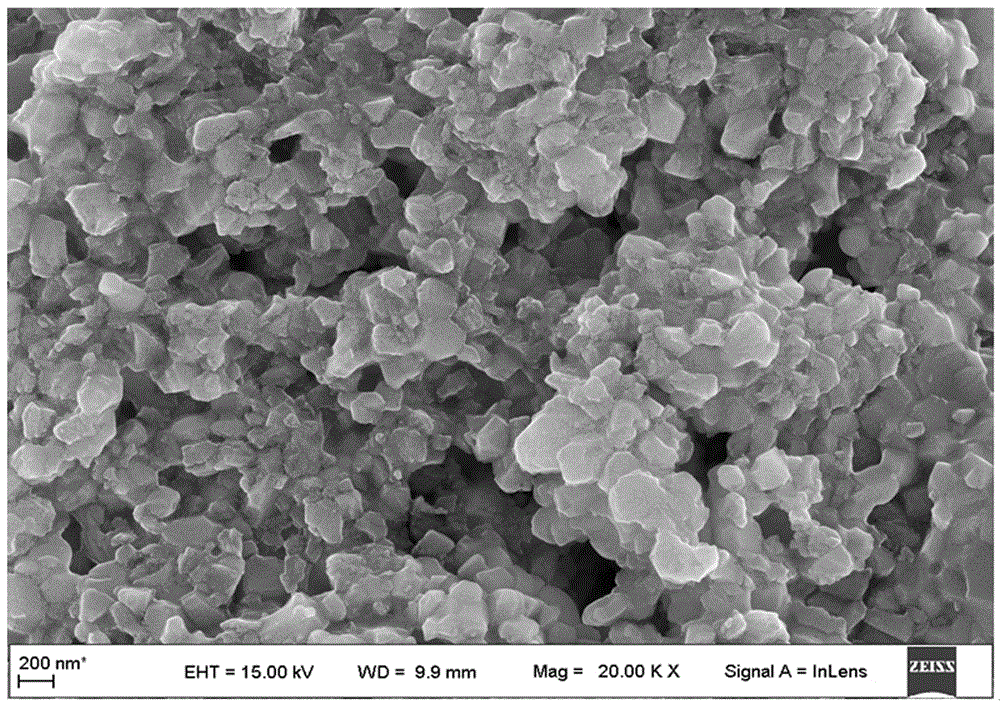

[0036] A method for preparing Mn-doped lanthanum titanate photocatalyst fluorescent powder, comprising the following steps.

[0037] According to the general formula Mn x La 2-x TiO 5-0.5x (Where the stoichiometric ratio of x=(0.01, 0.02, 0.06, 0.1, 0.14, 0.2, 0.4) weigh xmmol manganese acetate (Mn(CH 3 COO) 2 , A.R.), weighed (2-x) mmol of lanthanum acetate (La(CH 3 COO) 3, A.R.), respectively dissolved in 50ml distilled water to prepare solution A; Weigh 0.5 (2-x) mmoL tetrabutyl titanate and dissolve them in 40mL ethanol, add 6ml nitric acid (38% concentrated nitric acid) dropwise, and dissolve completely Obtain solution B; slowly pour B into A, magnetically stir for 1h, 800r / min, to obtain precursor sol C; then put it in a constant temperature water bath at 70°C, heat for about 8h, and obtain a colloidal precipitate, that is, the precursor gel ;Add 10mL of absolute ethanol and 1g of citric acid to the precursor gel, continue to stir for 0.2h, then put it into an oven...

Embodiment 2

[0040] A method for preparing Mn-doped lanthanum titanate photocatalyst fluorescent powder, comprising the following steps.

[0041] According to the general formula Mn x La 2-x TiO 5-0.5x (Where the stoichiometric ratio of x=(0.02, 0.06, 0.1, 0.14, 0.4) weigh xmmol manganese acetate (Mn(CH 3 COO) 2 , A.R.), weighed (2-x) mmol of lanthanum acetate (La(CH 3 COO) 3 , A.R.), respectively dissolved in 40ml of distilled water to prepare solution A; weigh 0.5(2-x) tetrabutyl titanate and dissolve them in 50mL of ethanol, add 6ml of nitric acid (38% concentrated nitric acid) dropwise, and completely dissolve to obtain Solution B; slowly pour B into A, magnetically stir for 1h, 500r / min, to obtain precursor sol C; then put it in a constant temperature water bath at 70°C, heat for about 8h, and obtain a colloidal precipitate, that is, a precursor gel; Add 20mL of absolute ethanol and 1.5g of citric acid to the precursor gel, continue to stir for 0.5h, then put it into an oven, an...

Embodiment 3

[0044] A method for preparing Mn-doped lanthanum titanate photocatalyst fluorescent powder, comprising the following steps.

[0045] Weigh 1.99mmoL lanthanum carbonate, 0.01mmoL manganese carbonate dissolved in 45ml distilled water, stir well to obtain solution A; weigh 1mmoL tetrabutyl titanate and dissolve it in 30mL methanol, add dropwise 6ml nitric acid (38% concentrated nitric acid), completely Dissolve to obtain solution B; slowly pour B into A, magnetically stir for 1h, 800r / min, to obtain precursor sol C; then put it in a constant temperature water bath at 50°C, and heat for about 12h to obtain a colloidal precipitate, that is, the precursor sol gel; add 10mL ethanol and 1g citric acid to the precursor gel, and continue to stir for 0.3h; then put it into an oven, 90°C self-propagating reaction for 45min; keep it at 180°C for 2h, and finally put the precursor into a corundum crucible, Put it into a muffle furnace, and calcined at 800° C. for 3.5 hours to obtain a photoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com