Preparation of nano composite material high-wax-content heavy oil viscosity reducer and performance testing

A thick oil viscosity reducer and nanocomposite material technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the cumbersome and complicated treatment of emulsified viscosity reducer, low viscosity reduction rate of oil-soluble viscosity reducer, and Problems such as poor coagulation viscosity reduction effect, etc., to achieve the effect of easy mass production, easy promotion, and good viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

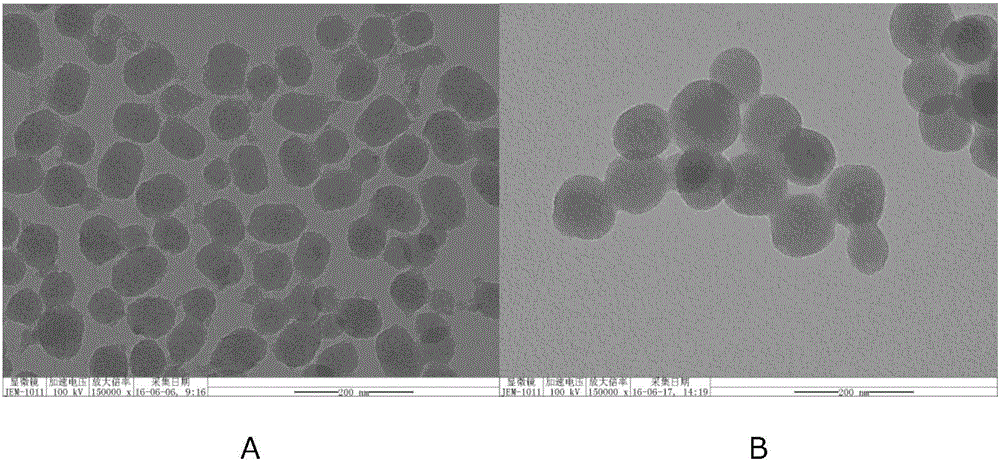

Image

Examples

Embodiment 1

[0046] Embodiment 1: the preparation method of polyoctearyl methacrylate-acrylamide / MSN, the steps are as follows:

[0047] Synthetic MSN:

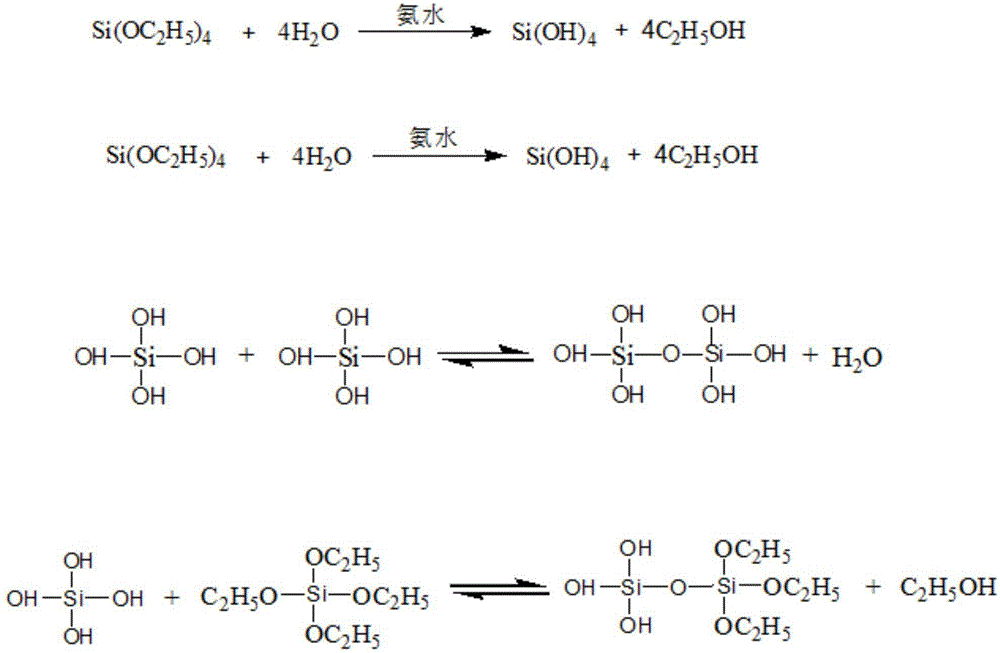

[0048] Add 108ml distilled water and 0.5g CTAB successively in the reactor, stir at a certain temperature, CTAB (hexadecyltrimethylammonium bromide) is completely dissolved, add 2ml of ammonia water, the whole system is kept at a certain temperature and continuously Stir. Stir at a constant speed of 1500 rpm to make it evenly mixed, and after 15 minutes, add 2 ml of TEOS (tetraethyl orthosilicate). Slowly raise the temperature to 60°C and keep it, and react for 24 hours to ensure the completion of the reaction. Then, centrifuge, wash, and dry. Obtain ordered mesoporous silica microspheres (MSN) using neutral template and water as solvent;

[0049] Surface and pore pre-modification of MSN by silane coupling agent:

[0050] Add 50ml of absolute ethanol, 1ml of acetic acid, 1ml of distilled water, and 1ml of γ-methacryloxypropyltrimethy...

Embodiment 2

[0061] The preparation method of embodiment 2 nanometer polyoctadecyl methacrylate-acrylamide / MSN, step is with embodiment 1, and difference is in (1) step, replaces hexadecane with octadecyltrimethylsilane trimethylammonium bromide.

Embodiment 3

[0062] The preparation method of embodiment 3 nanometer polyoctadecyl methacrylate-acrylamide / MSN, step is the same as embodiment 1, and difference is that in (2) replace gamma-methyl with 3-aminopropyltriethylsilane Acryloxypropyltrimethylsilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com