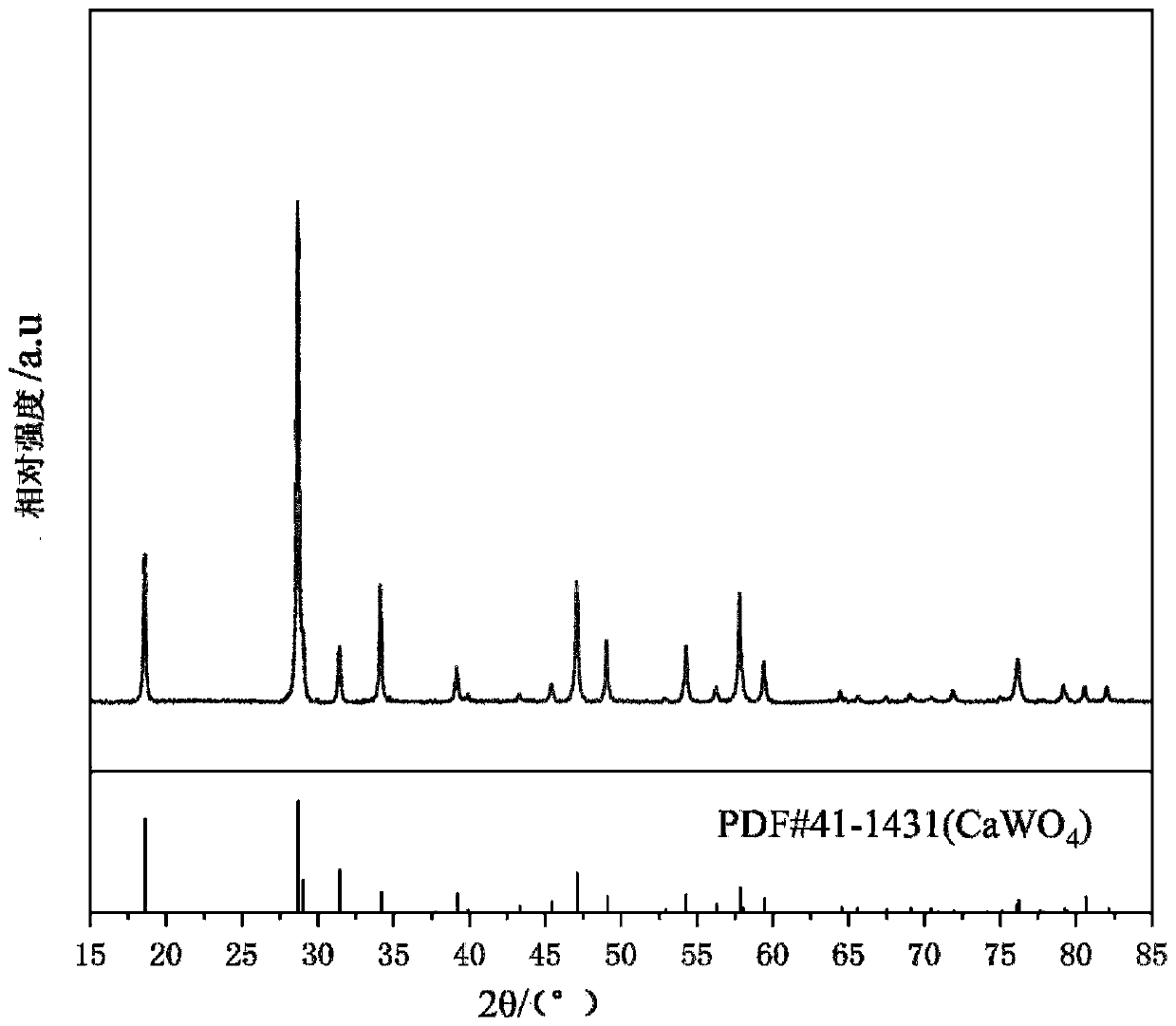

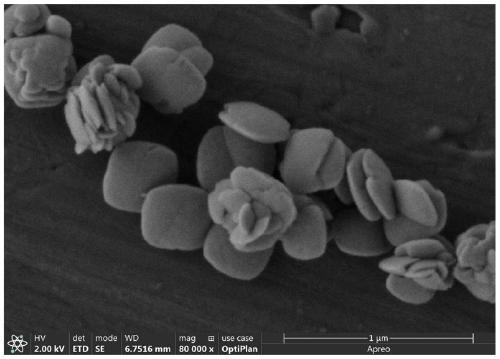

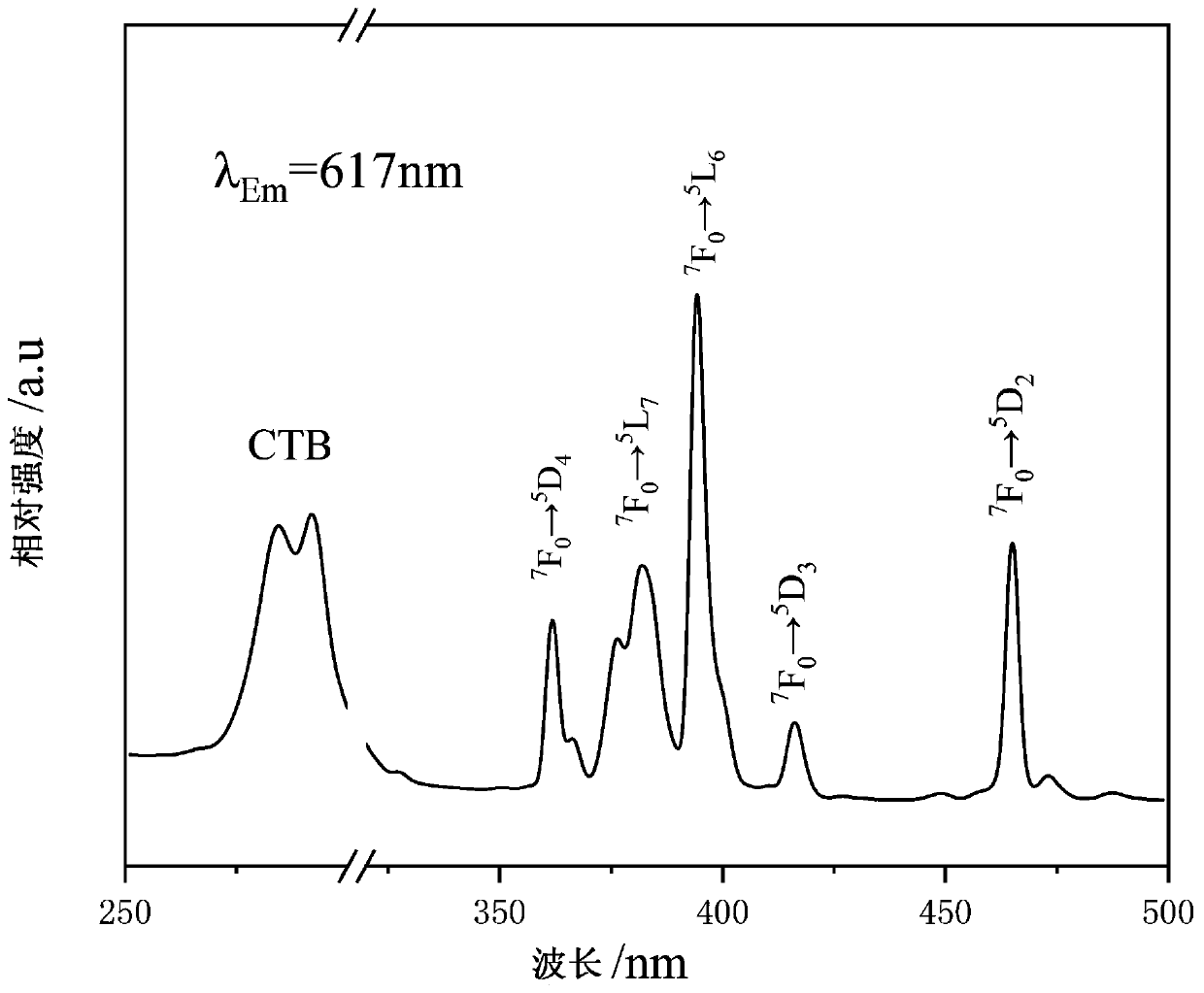

Preparation method of tungstate red phosphor

A technology of red phosphor and tungstate, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of poor thermal stability, low luminous efficiency of red phosphor, low synthesis temperature, etc., and achieve good luminous performance , high color purity, uniform doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1, according to calcium nitrate Ca(NO 3 ) 2 4H 2 O, gadolinium nitrate Gd(NO 3 ) 3 ·6H 2 O, europium nitrate Eu(NO 3 ) 3 ·6H 2 O and sodium tungstate Na 2 WO 4 2H 2 The molar ratio of O was 1:0.9:1.1:8 for experiments. Its specific steps are: first, calcium nitrate Ca(NO 3 ) 2 4H 2 O, gadolinium nitrate Gd(NO 3 ) 3 ·6H 2 O, europium nitrate Eu(NO 3 ) 3 ·6H 2 O and sodium tungstate Na 2 WO 4 2H 2 O was dissolved in deionized water respectively, and prepared into 1 mol / L calcium nitrate solution, 1 mol / L gadolinium nitrate solution, 1 mol / L europium nitrate solution, and 2 mol / L sodium tungstate solution for use.

[0035] Then measure 5ml of calcium nitrate solution, 4.5ml of gadolinium nitrate solution, and 5.5ml of europium nitrate solution for magnetic stirring and mixing for 12 minutes to obtain mixed solution A; under magnetic stirring, drop mixed solution A into 20ml of sodium tungstate solution , a white precipitate appeared during the r...

Embodiment 2

[0038] In step 1, the experiment is carried out according to the molar ratio of calcium nitrate, gadolinium nitrate, europium nitrate and sodium tungstate being 1:1.1:0.9:6. Its specific steps are: first, calcium nitrate Ca(NO 3 ) 2 4H 2 O, gadolinium nitrate Gd(NO 3 ) 3 ·6H 2 O, europium nitrate Eu(NO 3 ) 3 ·6H 2 O and sodium tungstate Na 2 WO 4 2H 2 O was dissolved in deionized water respectively, and prepared into 1 mol / L calcium nitrate solution, 1 mol / L gadolinium nitrate solution, 1 mol / L europium nitrate solution, and 2 mol / L sodium tungstate solution for use.

[0039] Then measure 5ml of calcium nitrate solution, 5.5ml of gadolinium nitrate solution, and 4.5ml of europium nitrate solution for magnetic stirring and mixing for 15 minutes to obtain mixed solution A; under magnetic stirring, drop mixed solution A into 15ml of sodium tungstate solution , a white precipitate appeared during the reaction, and the reaction was completed to obtain a mixed solution B;...

Embodiment 3

[0042] Carry out the experiment of different pH according to the test condition of embodiment 2, wherein, the pH of adjusting mixed solution B in step 1 is respectively 7 and 9, obtains two groups of tungstate CaGd 1.1 Eu 0.9 (WO 4 ) 4 red phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com