Method of electroless nickel plating on silicon substrate microchannel

An electroless nickel electroplating and silicon microchannel technology, applied in microstructure technology, liquid chemical plating, microstructure devices, etc., can solve the problems of low toxicity and low cost, and achieve good crystalline state, low cost and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

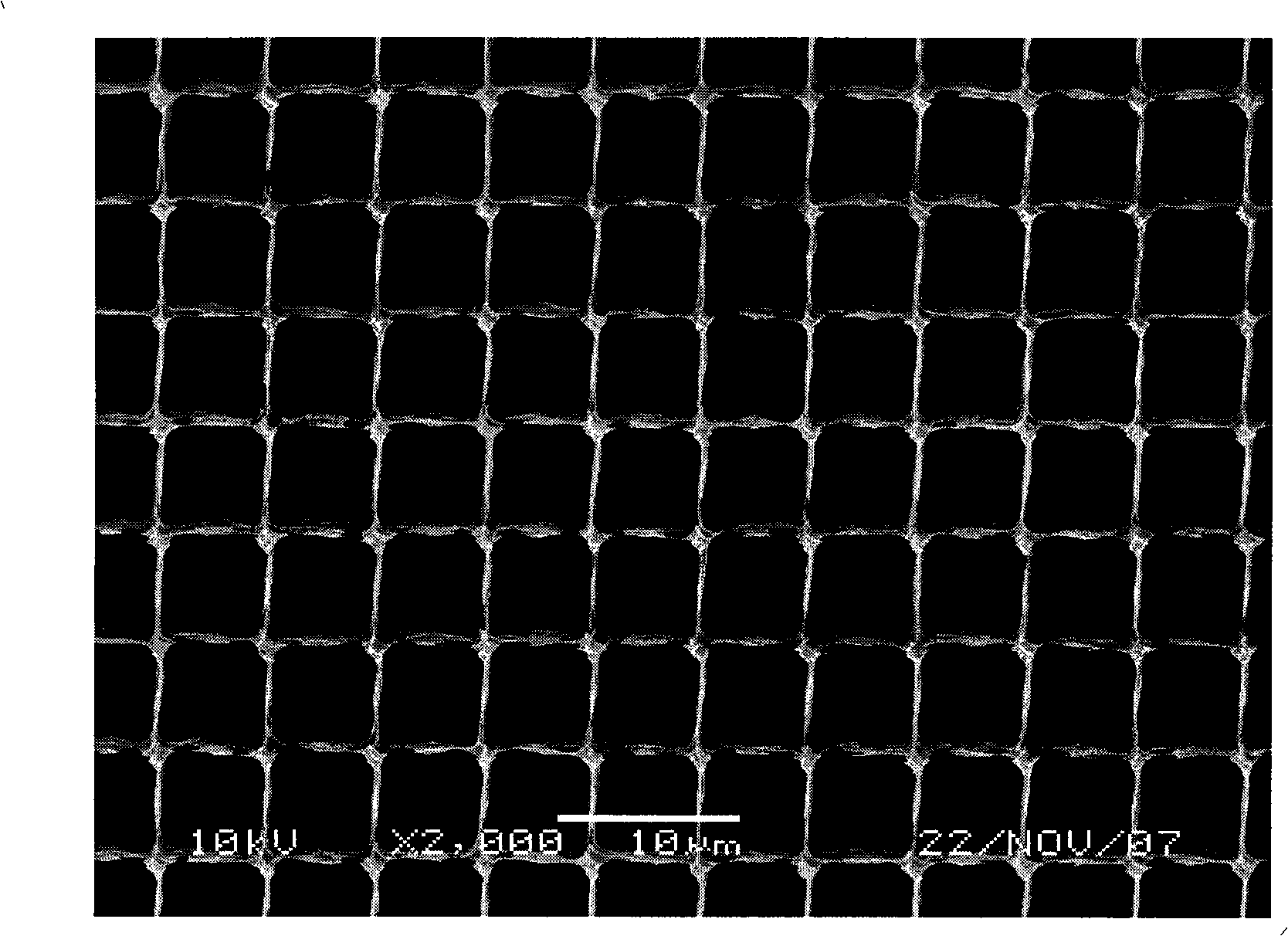

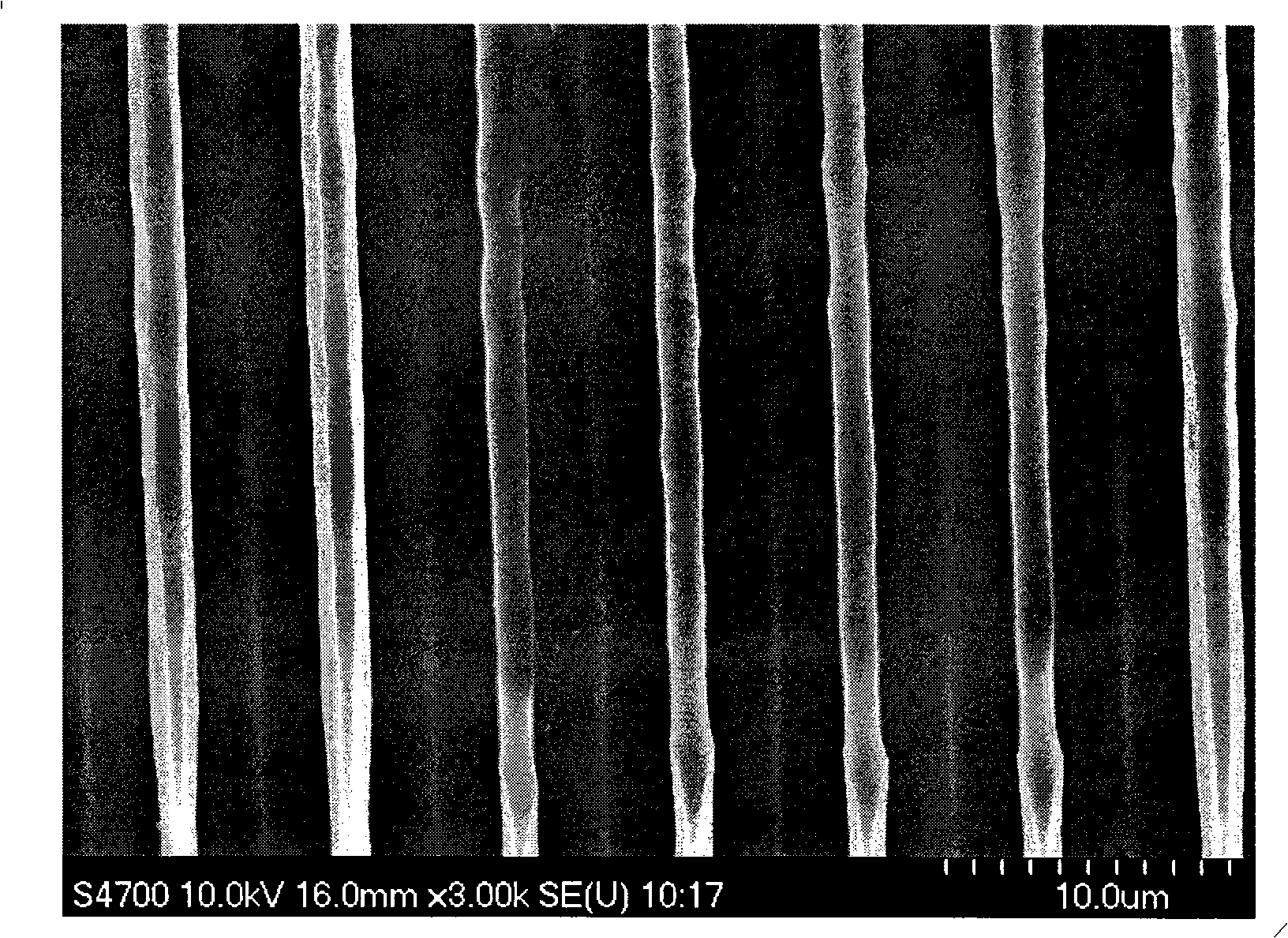

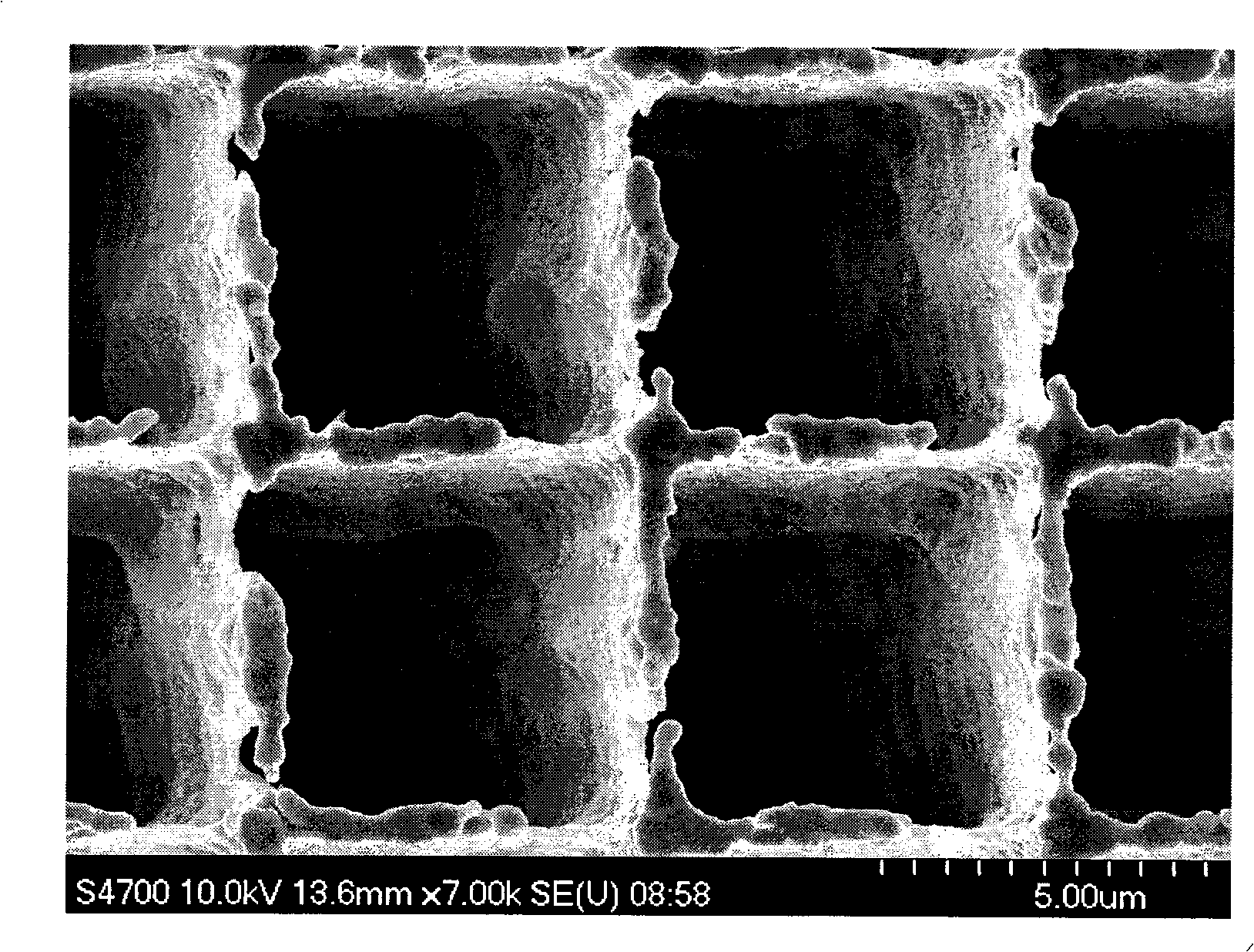

[0020] After the silicon microchannel sample is prepared, the prepared microchannel is immersed in an aqueous solution containing 1% TritonX-100 (polyethylene glycol octylphenyl ether) for 10 seconds. Nickel hexahydrate (NiSO 4 .6H 2 O) 1M / L, sodium dodecyl sulfate (Sodium dodecyl sulfate) 10mg, ammonium fluoride (NH 4 F) 2.5M / L, sodium citrate (Sodium citrate) 0.2M / L, ammoniacal liquor and ammonium sulfate 0.5M / L are configured into a solution, and the microchannel of step 1) is cleaned with deionized water and put into the solution, the solution Keep the pH value of the alkaline environment at 8, control the temperature at 85 degrees Celsius, and deposit for 5 minutes. After the deposition, take out the microchannel and rinse it with deionized water to obtain a 3D current collection layer with a high specific surface area.

Embodiment 2

[0022] After the silicon microchannel sample is prepared, the prepared microchannel is immersed in an aqueous solution containing 1% TritonX-100 (polyethylene glycol octylphenyl ether) for 30 seconds. Nickel hexahydrate (NiSO 4 .6H 2 O) 2M / L, sodium dodecyl sulfate (Sodium dodecyl sulfate) 20mg, ammonium fluoride (NH 4 F) 7.5M / L, sodium citrate (Sodium citrate) 0.4M / L, ammonia water and ammonium sulfate 1M / L are configured into a solution, and the microchannel in step 1) is washed with deionized water and put into the solution, and the solution remains alkaline The pH value of the active environment is 8, the temperature is controlled at 85 degrees Celsius, and the deposition is performed for 10 minutes. After the deposition, the microchannel is taken out and rinsed with deionized water to obtain a 3D current collection layer with a high specific surface area.

Embodiment 3

[0024] After the silicon microchannel sample is prepared, the prepared microchannel is immersed in an aqueous solution containing 1% TritonX-100 (polyethylene glycol octylphenyl ether) for 20 seconds. Nickel hexahydrate (NiSO 4 .6H 2 O) 1.5M / L, sodium dodecyl sulfate (Sodium dodecyl sulfate) 15mg, ammonium fluoride (NH 4 F) 5M / L, sodium citrate (Sodium citrate) 0.3M / L, ammonia water and ammonium sulfate 0.75M / L are configured into a solution, and the microchannel in step 1) is washed with deionized water and put into the solution, and the solution remains alkaline The pH value of the active environment is about 8.3, the temperature is controlled at 80 degrees Celsius, and the deposition is carried out for 8 minutes. After the deposition, the microchannel is taken out and rinsed with deionized water to obtain a 3D current collection layer with a high specific surface area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com