Method for producing magnesia carbon bricks for refining ladle lining by using waste magnesia carbon bricks

A technology of magnesia-carbon bricks and refined steel, which is applied in the production and application of ceramic materials, household appliances, etc., can solve the problems of resource and environmental waste, groundwater pollution, land waste, etc., to eliminate land, solve hazards, and reduce resource waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

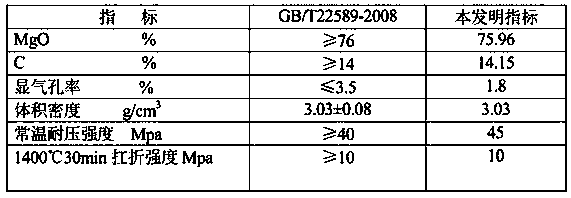

Examples

Embodiment 1

[0025] Example 1 The present invention uses waste magnesia-carbon bricks to produce magnesia-carbon bricks for refining ladle linings, which is made of waste magnesia-carbon bricks, 195 flake graphite, and high-temperature pitch powder (coal tar pitch that meets the GB / T2290-94 standard in a coking plant) ), MgO≥97% fused magnesium (bulk density≥3.45g / cm 3 , Ca / Si≥2.0), phenolic resin binder, antioxidant metal silicon, and metal aluminum are prepared according to the following proportions by weight:

[0026] Ingredients:

[0027] 62 parts of waste magnesia carbon bricks, including: 15-18 parts of granular materials with a particle size of 5-8mm, 12-15 parts of granular materials with a particle size of 3-5mm, 20 parts of granular materials with a particle size of 1-3mm, and fine powder with a particle size of ≤0.088mm 12 copies;

[0028] 8 parts of 195 flake graphite;

[0029] 2 parts of high temperature asphalt powder;

[0030] 30 parts of fused magnesium, including: 10 p...

Embodiment 2 application example

[0038] The finished magnesia-carbon brick prepared by the present invention is used in Tianjin Daqiang Iron and Steel Works: it is used on a Φ4600mm electric furnace. Due to the hot charging of molten iron in the other side, the furnace age reaches 1067 times (the traditional brick body furnace age is 230 times). Used on Tianjin Daqiang 50-ton refining ladle, the average ladle age is 92 times when the overall ladle is offline (the service life of traditional refining ladle is 45-50 times);

[0039] When used by Guangdong Taiye Metal Products Co., Ltd.: when it is used on an 80-ton refined steel ladle, and the ladle age reaches 83 times (the traditional refined steel ladle is used 65-70 times), due to the expiry of the service life of the breathable brick, the ladle is unpacked, 200mm The thinnest part of the brick is 125mm; when used on a Φ5200mm EBT electric furnace, the other side is 100% scrap steel, and the furnace life reaches between 392 and 415 times (the traditional ser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com