Grease composition for foods soft sandwich and preparation method thereof

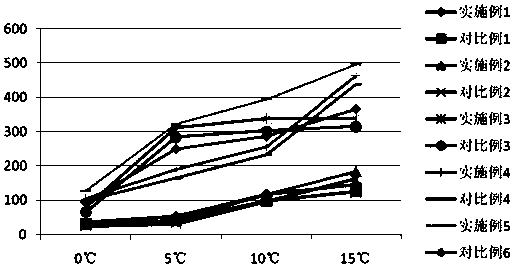

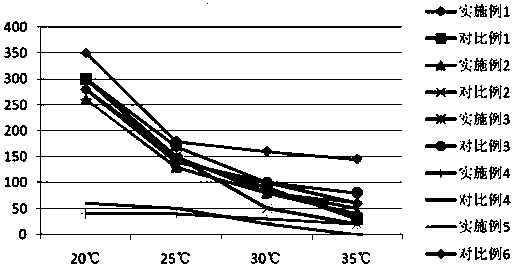

A technology of oil composition and edible oil, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of difficult winter and summer, too hard in winter, too soft in summer, etc., to solve the problem of too strong fluidity, improve The effect of the crystal state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

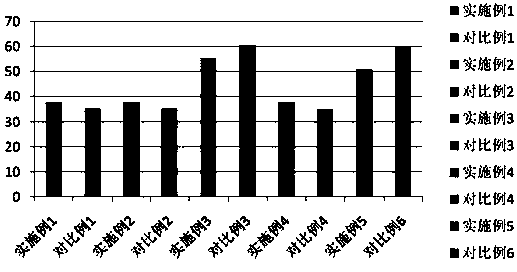

Examples

Embodiment 1

[0035] Prepare the fat composition for food soft sandwich of the present invention through the following steps:

[0036] Step 1. Grease selection: the total weight is set to 5000kg. A chooses palm oil with an iodine value of 50, the ratio is 80%; B chooses palm oil with an iodine value of 30, the ratio is 1%; C chooses soybean oil, the ratio is 18.9%; D chooses fully hydrogenated rapeseed oil, the ratio is 0.1%;

[0037] Step 2. Oil mixing: A, B, C, and D four oils are weighed in proportion, put a quarter of A in a blending tank with a capacity of 5000kg, then add D, heat to 70-75°C, Stir until D is completely dissolved. Cool down to 55-60°C, add three-quarters of A, B, and C, keep warm at 55-60°C, and stir for more than 60 minutes to completely mix evenly;

[0038] Step 3. Rapid cooling of oil: Cool the mixed oil to 50°C through a pre-cooler, then cool it to an oil temperature of 10-25°C through a 2-3 stage quenching machine, and fill it into the container through a grease ...

Embodiment 2

[0042] Prepare the fat composition for food soft sandwich of the present invention through the following steps:

[0043] Step 1. Grease selection: the total weight is set to 5000kg. A chooses palm oil with an iodine value of 50, the ratio is 80%; B is not used; C chooses rapeseed oil, the ratio is 19.9%; D chooses fully hydrogenated soybean oil, the ratio is 0.1%;

[0044] Step 2. Grease mixing: After weighing the three kinds of fats A, C, and D in proportion, put a quarter of A into a blending tank with a capacity of 5000kg, then add D, heat to 70-75°C, and stir until D is completely melted. Cool down to 55-60°C, add 3 / 4 of A and C, keep warm at 55-60°C, stir for more than 60 minutes to completely mix;

[0045] Step 3. Rapid cooling of oil: Cool the mixed oil to 50°C through a pre-cooler, then cool it to an oil temperature of 10-25°C through a 2-3 stage quenching machine, and fill it into the container through a grease filling machine;

[0046] Step 4. Fat solidification: ...

Embodiment 3

[0049] Prepare the fat composition for food soft sandwich of the present invention through the following steps:

[0050] Step 1. Oil selection: the total weight is set to 5000kg, and A and B are not used; C chooses corn oil, the ratio is 80%; D chooses fully hydrogenated palm oil, the ratio is 20%;

[0051] Step 2. Oil mixing: After weighing the two oils C and D in proportion, put a quarter of C into a blending tank with a capacity of 5000kg, then add D, heat to 70-75°C, and stir until D is completely melted. Cool down to 60-65°C, add the remaining three-quarters of C, keep warm at 60-65°C, and stir for more than 60 minutes to completely mix;

[0052] Step 3. Rapid cooling of oil: Cool the mixed oil to 55°C through a pre-cooler, then cool it to an oil temperature of 10-25°C through a 2-3 stage quenching machine, and fill it into the container through a grease filling machine;

[0053] Step 4. Fat solidification: Put the fat in a place at 5-25° C. to mature for 24 hours to so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com