Preparation method of thermal spraying powder for ferrite corrosion-resistant coating

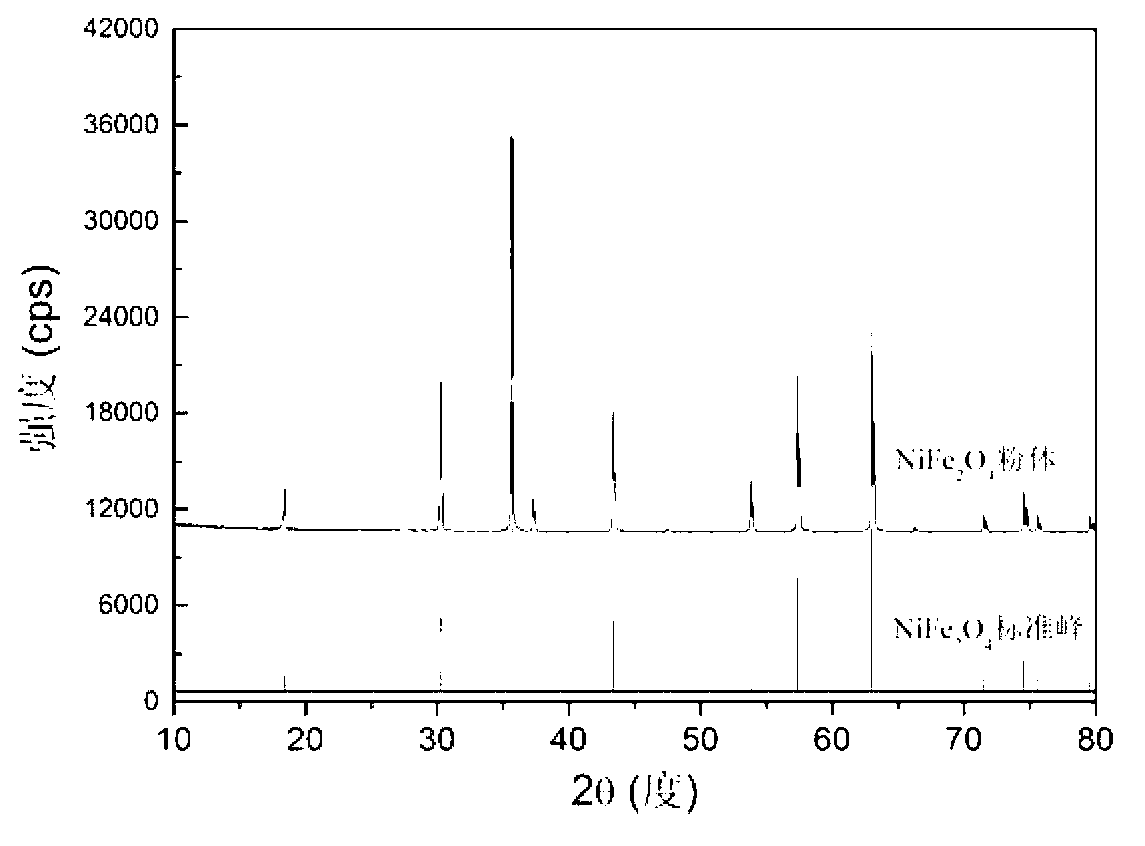

A technology of thermal spraying and powder, which is applied in the field of preparation of nickel ferrite (NiFe2O4) thermal spraying powder, which can solve the problem that nickel ferrite powder cannot meet the requirements of thermal spraying powder, complex production process and equipment, Problems such as poor crystallization state of crystal grains, to achieve the effect of simple and controllable process flow and equipment, good crystallization state of crystal grains, and uniform distribution of grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

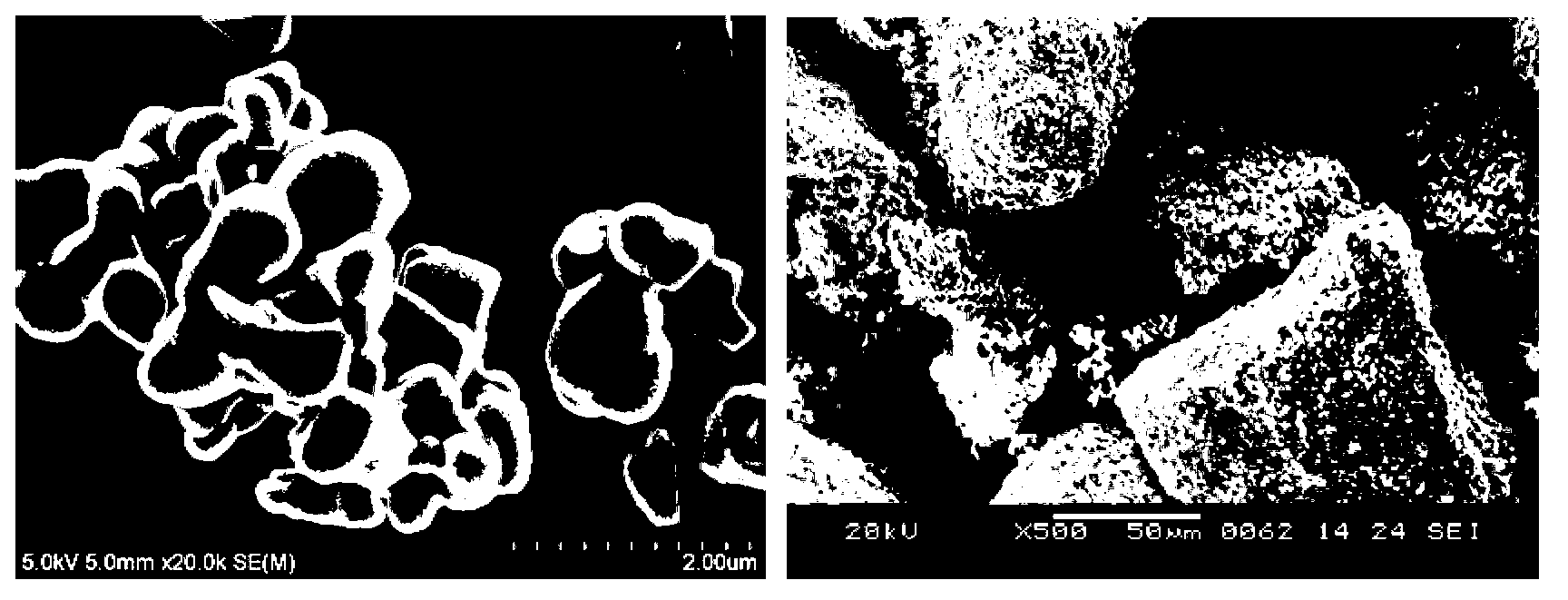

Embodiment 1

[0034] The purity is 99.9% Fe 2 o 3 and NiO powder with a purity of 99.9% are placed in a ball mill tank at a ratio of 2:1, and ZrO is added 2 Grinding balls and ball milling medium (concentration: 75% industrial alcohol), the ratio of ball to material is 4:1, the speed of ball milling is 400r / min, and the milling time is 6 hours. Using a rotary evaporator to perform high-temperature rotary evaporation on the slurry obtained by ball milling to obtain Fe 2 o 3 Mix the powder with NiO, and then place it in a high-temperature drying oven for 24 hours to obtain dry Fe 2 o 3 Mix powder with NiO. The evaporation temperature is 80°C, the rotation speed is 100r / min, and the drying oven temperature is 120°C. The resulting dry Fe 2 o 3 Mix powder with NiO and pass through 300 mesh sieve. Use a high temperature sintering furnace to calcine the sieved powder to synthesize NiFe 2 o 4 For high-purity powder, the calcination temperature is 1200°C, the calcination time is 1.5 hours...

Embodiment 2

[0038] The purity is 99.9% Fe 2 o 3 and NiO powder with a purity of 99.9% are placed in a ball mill jar at a molar ratio of 1:1, and ZrO is added 2 Grinding balls and ball milling medium (concentration: 75% industrial alcohol), the ball-to-material ratio is 4:1, the ball milling speed is 400r / min, and the ball milling time is 8 hours. Using a rotary evaporator to perform high-temperature rotary evaporation on the slurry obtained by ball milling to obtain Fe 2 o 3 Mix the powder with NiO, and then place it in a high-temperature drying oven for 36 hours to obtain dry Fe 2 o 3 Mix powder with NiO. The evaporation temperature is 70°C, the rotation speed is 100r / min, and the drying oven temperature is 110°C. The resulting dry Fe 2 o 3 Mix powder with NiO and pass through 300 mesh sieve. Use a high temperature sintering furnace to calcine the sieved powder to synthesize NiFe 2 o 4 For high-purity powder, the calcination temperature is 1050°C, the calcination time is 4 hou...

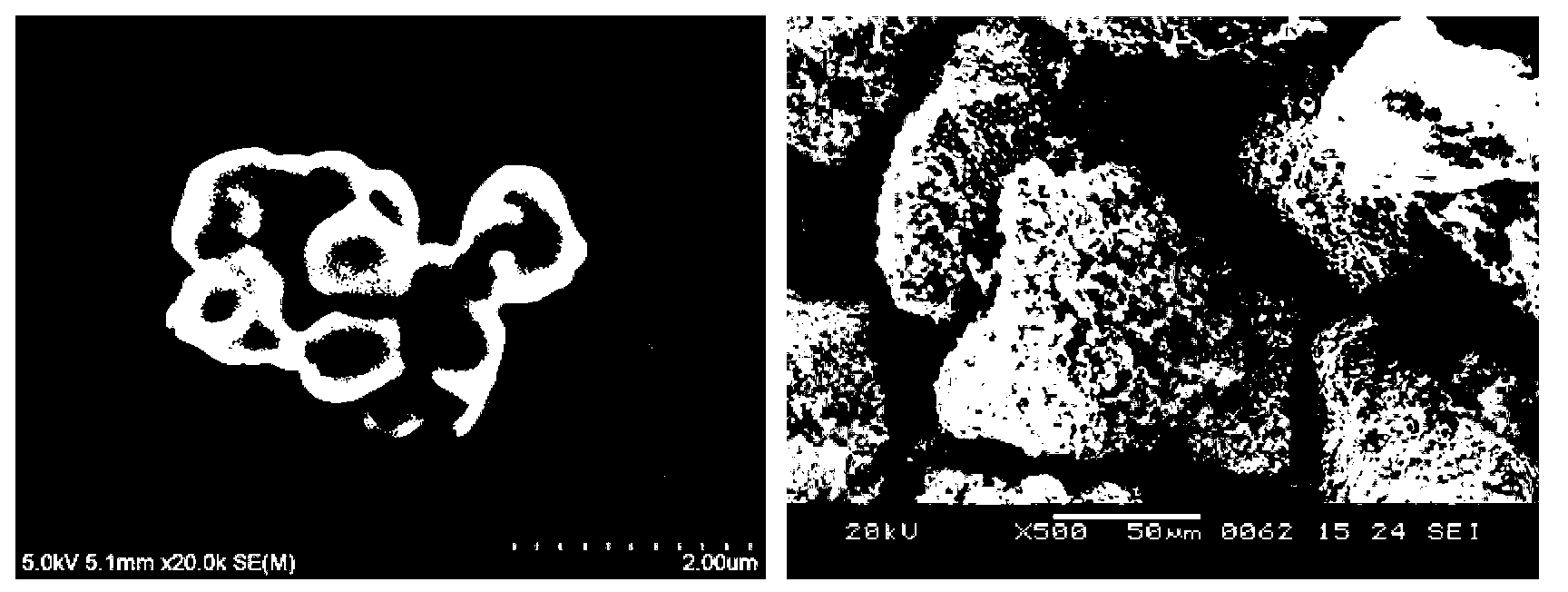

Embodiment 3

[0041] Fe with a purity of 99.9% 2 o 3 and NiO powder in a ratio of 1.5:1 and placed in a ball mill tank, and added ZrO 2 Grinding balls and ball milling medium (concentration: 75% industrial alcohol), the ratio of ball to material is 4:1, the speed of ball milling is 400r / min, and the milling time is 6 hours. Using a rotary evaporator to perform high-temperature rotary evaporation on the slurry obtained by ball milling to obtain Fe 2 o 3 Mix the powder with NiO, and then place it in a high-temperature drying oven for 24 hours to obtain dry Fe 2 o 3 Mix powder with NiO. The evaporation temperature is 80°C, the rotation speed is 100r / min, and the drying oven temperature is 120°C. The resulting dry Fe 2 o 3 Mix powder with NiO and pass through 300 mesh sieve. Use a high temperature sintering furnace to calcine the sieved powder to synthesize NiFe 2 o 4 For high-purity powder, the calcination temperature is 1100°C, the calcination time is 3 hours, and the calcination a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com