Iron powder reducing method for simultaneously producing organic product and ferric oxide black

A technology of iron oxide black and reduction method, applied in organic chemistry methods, organic chemistry, chemical instruments and methods, etc., can solve the problems of low iron sludge grade, low production efficiency, environmental pollution, etc., and achieve good performance and high tinting strength. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

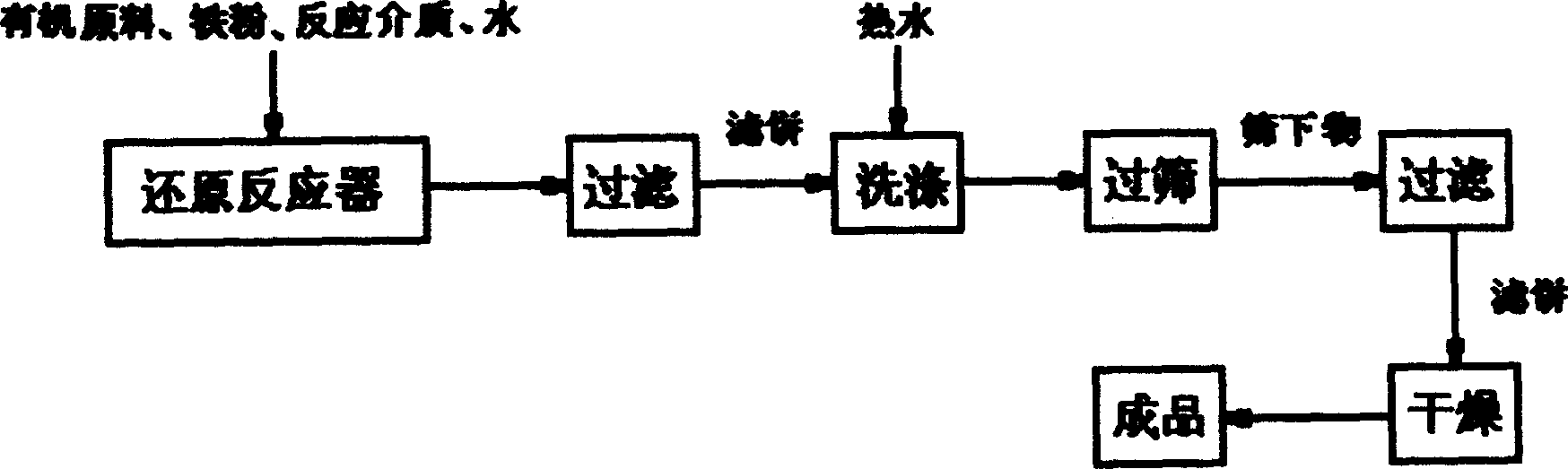

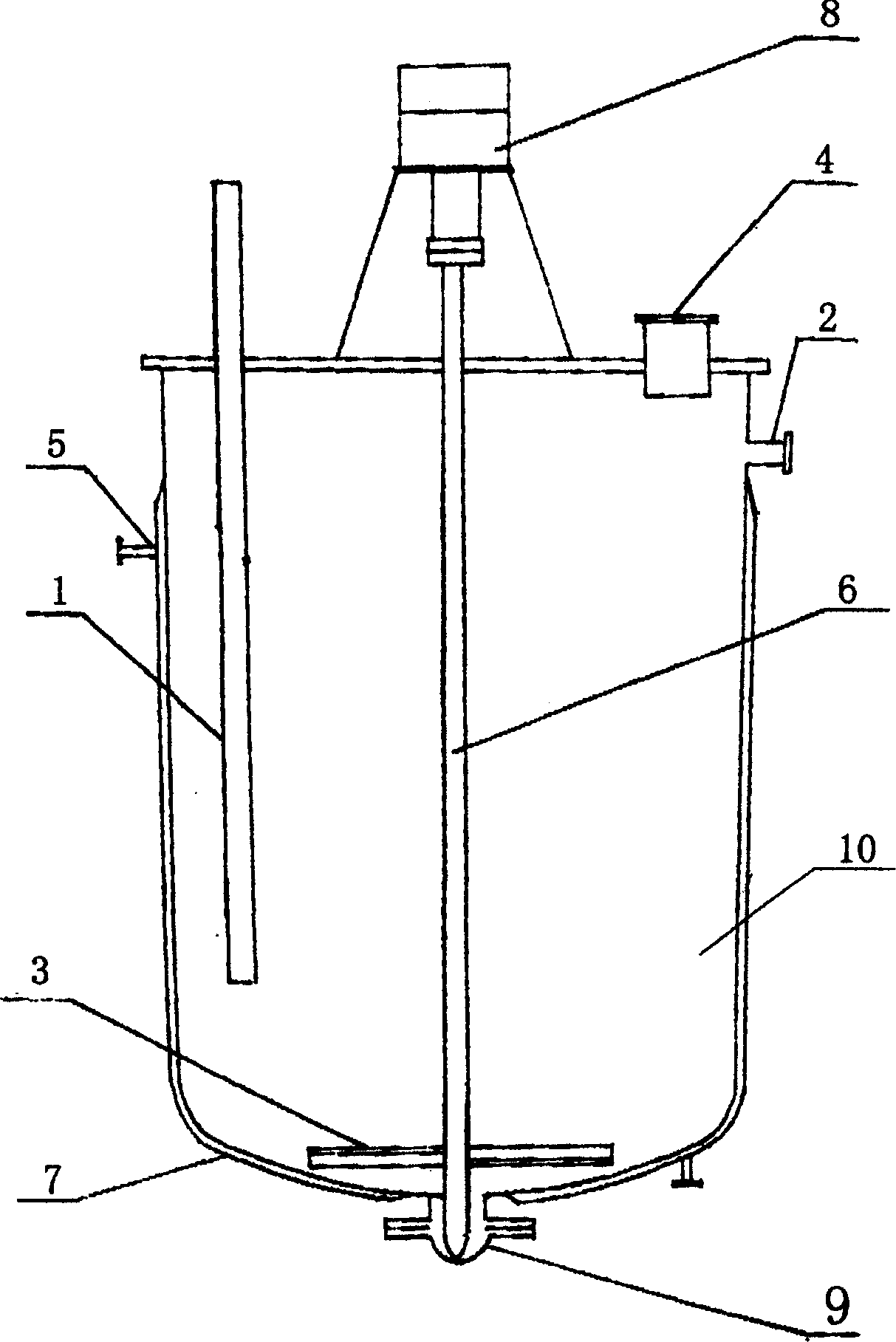

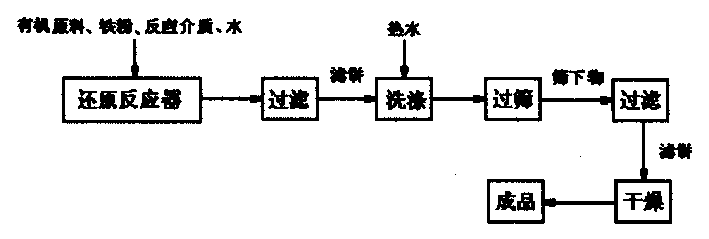

Method used

Image

Examples

Embodiment 1

[0040] Take 85 grams of iron powder, 8 grams of ferrous nitrate, and 150 milliliters of water, and add them to a 2000 milliliter container (the upper part has a discharge port) at the same time, turn on the paddle stirrer to stir and disperse, heat the reaction for 1 hour, control the pH of the solution to 5, and then Slowly add 770 milliliters of 10% p-benzoquinone solution dropwise. After the p-benzoquinone solution is dropped, add 85 grams of iron powder, 8 grams of ferrous nitrate and 150 milliliters of water at one time, and then continue to drop p-benzoquinone Solution 770 ml. Control the stirring speed to 80 rpm. Filter 900 ml of the discharged suspension, wash the filter cake with heated water until the supernatant is colorless, then sieve (the sieve aperture is less than 45 microns), filter, and put the solid phase iron sludge into the CLS101-E type In an oven, dry at 65°C-75°C and grind to obtain 102 grams of finished ferric oxide. The detection tinting strength is...

Embodiment 2

[0042] Take 1.4 tons of iron powder, 40 kg of ferrous chloride, 40 kg of ferrous sulfate, and 2,500 liters of water, add them to a 5,000 liter stainless steel reaction tank, turn on the paddle stirrer to stir and disperse, heat to a temperature of 80°C, and react for 2 hours. The pH of the solution is 6, and slowly add 1000 liters of nitrobenzene solution dropwise to it. After all the nitrobenzene is added dropwise, add 1.4 tons of iron powder, 40 kg of ferrous chloride, and 40 kg of sulfurous acid at one time. And 2500 liters of water, then continue to drop 1000 liters of nitrobenzene solution. Control the stirring speed to 85 rpm. Filter 3800 liters of the discharged suspension, wash the filter cake with heated water until the supernatant is colorless, then sieve (the sieve aperture is less than 45 microns), filter, and put the solid phase iron sludge into the GSX800 type flash evaporation Dried in a drier with a controlled temperature of 200°C to obtain 1.68 tons of finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com