Mesoporous-structure metal nickel catalyst and its preparing method and use

A technology of mesoporous structure and metal nickel, which is applied in the field of mesoporous structure metal nickel catalyst and its preparation, and achieves excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Preparation of amine functionalized SBA-15 template

[0025] At 40°C, add 2g of P123 and 62.5mL of 2M hydrochloric acid, stir until the surfactant is completely dissolved; then add 4.2mL of tetraethyl orthosilicate (TEOS) and continue stirring for 3h; add 0.47mL of 3-aminopropyl-trimethoxy base silane, continue to stir at the same temperature for 24 hours; transfer the resulting mixed solution to a polytetrafluoroethylene water thermos bottle, and hydrothermally react in an oven at 100 ° C for 24 hours; cool, filter, wash, and vacuum dry. Obtain a white powder; reflux 1.0 g of the above white powder with 500 mL of absolute ethanol for 24 h; suction filter, wash, and dry to obtain the amine-functionalized SBA-15 template, which is denoted as NH 2 -SBA-15.

[0026] 2) Preparation of chemical plating solution

[0027] Prepare 50mL electroless plating solution, its composition is: 0.1mol / L NiSO 4 ·6H 2 O, 0.25mol / LNiCl 2 ·6H 2 O, 0.085mol / L Na 3 C 6 h 5 o 7 2H ...

Embodiment 2

[0038] 1) Preparation of amine functionalized SBA-15 template

[0039] At 40°C, add 2g of P123 and 62.5mL of 2M hydrochloric acid, stir until the surfactant is completely dissolved; then add 4.2mL of tetraethyl orthosilicate (TEOS) and continue stirring for 3h; add 1.1mL of 3-aminopropyl-trimethoxy base silane, continue to stir at the same temperature for 24 hours; transfer the resulting mixed solution to a polytetrafluoroethylene water thermos bottle, and hydrothermally react in an oven at 100 ° C for 24 hours; cool, filter, wash, and vacuum dry. Obtain a white powder; reflux 1.0 g of the above white powder with 500 mL of absolute ethanol for 24 h; suction filter, wash, and dry to obtain the amine-functionalized SBA-15 template, which is denoted as NH 2 -SBA-15.

[0040] All the other steps are the same as in Example 1.

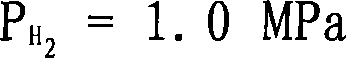

[0041] After BET detection, the specific surface area of the obtained sample is 152m 2 / g.

Embodiment 3

[0043] 1) Preparation of amine functionalized SBA-15 template

[0044] At 40°C, add 2g of P123 and 62.5mL of 2M hydrochloric acid, stir until the surfactant is completely dissolved; then add 4.2mL of tetraethyl orthosilicate (TEOS) and continue stirring for 3h; add 0.21mL of 3-aminopropyl-trimethoxy base silane, continue to stir at the same temperature for 24 hours; transfer the resulting mixed solution to a polytetrafluoroethylene water thermos bottle, and hydrothermally react in an oven at 100 ° C for 24 hours; cool, filter, wash, and vacuum dry. Obtain a white powder; reflux 1.0 g of the above white powder with 500 mL of absolute ethanol for 24 h; suction filter, wash, and dry to obtain the amine-functionalized SBA-15 template, which is denoted as NH 2 -SBA-15.

[0045] All the other steps are the same as in Example 1.

[0046] After BET detection, the specific surface area of the obtained sample is 96m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com