Application of supported palladium catalyst in selective hydrogenation reaction

A technology of supported palladium and hydrogenation reaction, which is applied in catalysts, molecular sieve catalysts, carbon compound catalysts, etc., and can solve problems not involved in catalyst applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Silanization Modification of All-Silicon MCM-41

[0032] Weigh 3 g of all-silicon MCM-41 and place it in 150 mL of toluene, then add trimethylchlorosilane (5% by volume), stir and reflux at 110° C. for 3 h, and filter with suction. The filter cake was washed with toluene and dried at room temperature for 10 hours to obtain silanized MCM-41, designated as S-MCM-41.

Embodiment 2

[0037] Preparation of Pd Catalyst Precursor Supported by S-MCM-41

[0038] Prepare the Pd catalyst precursor supported by S-MCM-41 by equal-volume impregnation method: dissolve 0.022 g of palladium acetate in 5 mL of toluene, and then add it dropwise to 2 g of S-MCM-41, stirring while adding , until all the impregnating liquid is added dropwise. Aged at room temperature for 10 hours, then dried in an oven at 120°C for 12 hours, raised to 400°C in a muffle furnace at a rate of 1°C / min, and calcined for 5 hours to obtain a catalyst precursor.

Embodiment 3

[0040] Preparation of Supported Pd Catalyst

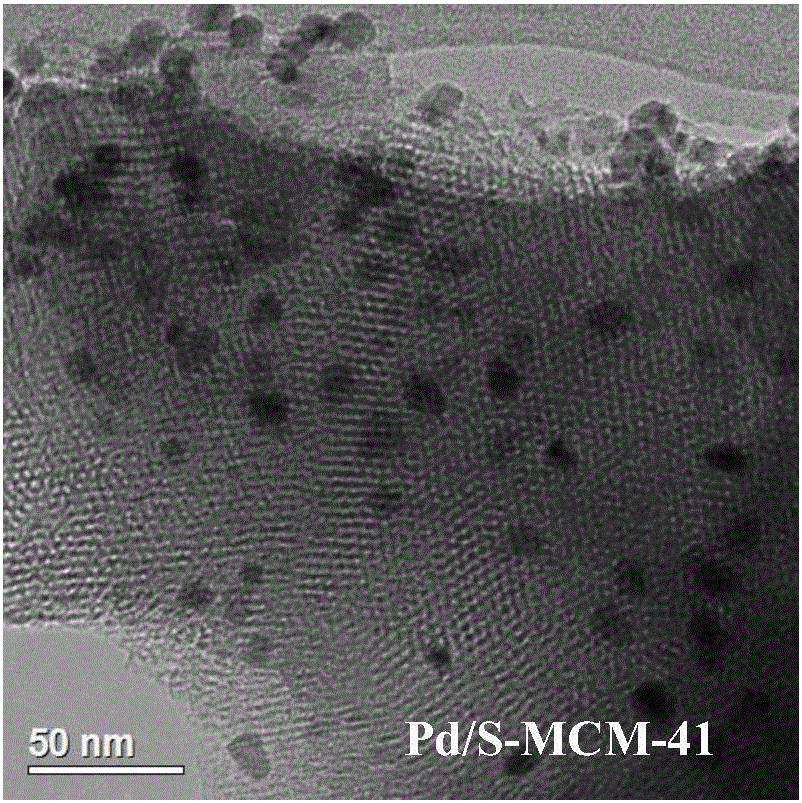

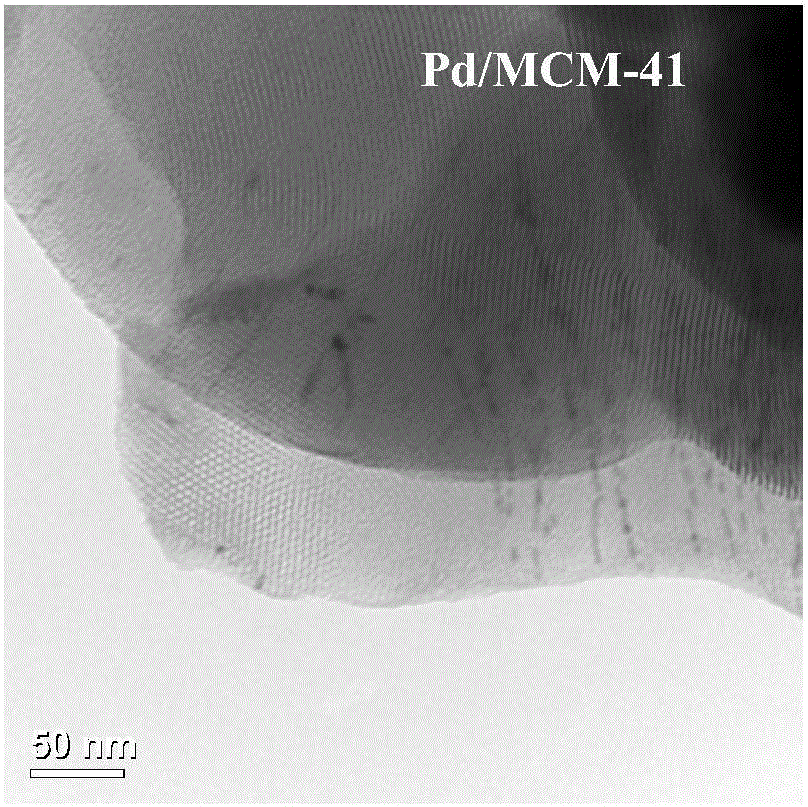

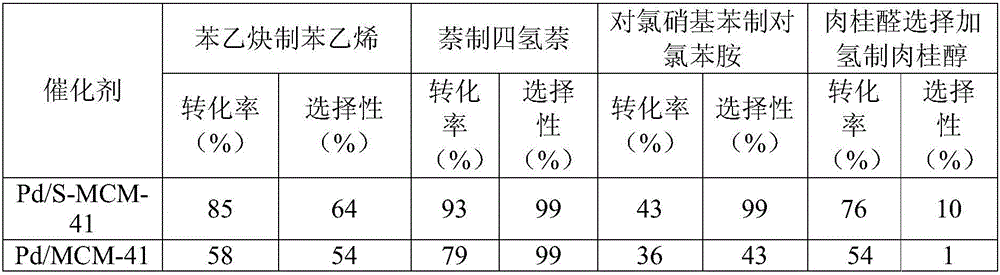

[0041] The catalyst precursor described in Comparative Example 1 and Example 2 was pressed into tablets and crushed to 20-40 meshes, then 0.05 g of the catalyst precursor was placed in a fixed-bed reactor with an inner diameter of 8 mm, and prepared by temperature-programmed reduction supported Pd catalyst. The specific conditions are as follows: in a hydrogen atmosphere with a total pressure of 1.0MPa, the temperature is raised from room temperature to 300°C at a rate of 10°C / min, and the gas flow rate is 75NmL / min. Pd catalyst. They are respectively denoted as Pd / S-MCM-41 and Pd / MCM-41, and their transmission electron microscope photos are as follows Figure 1A , Figure 1B shown by Figure 1A and Figure 1B It can be seen from the electron micrographs shown that the distribution of Pd in MCM-41 is different from that in S-MCM-41. In Pd / MCM-41, Pd is distributed inside the mesoporous channels of MCM-41; while in Pd / S-MCM-41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com