Molybdenum disulfide nano-sheet film material and its preparation methods

A technology of molybdenum disulfide and thin film materials, applied in the directions of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of cumbersome preparation process and inconvenient promotion, and achieve the effects of good repeatability, simple synthesis method and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A. Take the titanium sheet, put it into concentrated hydrochloric acid and ultrasonically wash it, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0037] B. Prepare 0.25mol / L (NH 4 ) 6 Mo 7 o 24 4H 2 O aqueous solution 4ml, 0.15mol / L thiourea aqueous solution 4ml, mix above-mentioned two solutions, then add 30ml of deionized water, stir fully to obtain homogeneous and stable solution, then transfer to 40ml autoclave; Inclined into the reactor. Heat water at 180°C for 12 hours, and cool to room temperature with cooling water after the reaction is complete.

[0038] C. Take out the titanium sheet in the reaction kettle, wash it with deionized water and ethanol, dry it, and dry it at 80° C. for 1 hour to obtain the product.

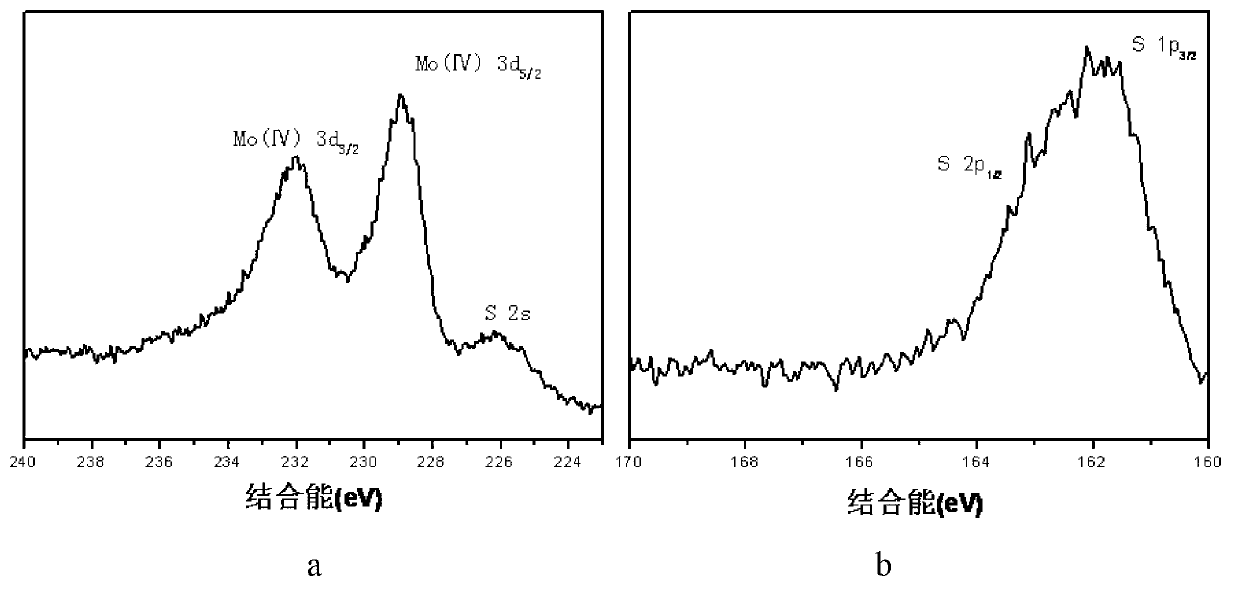

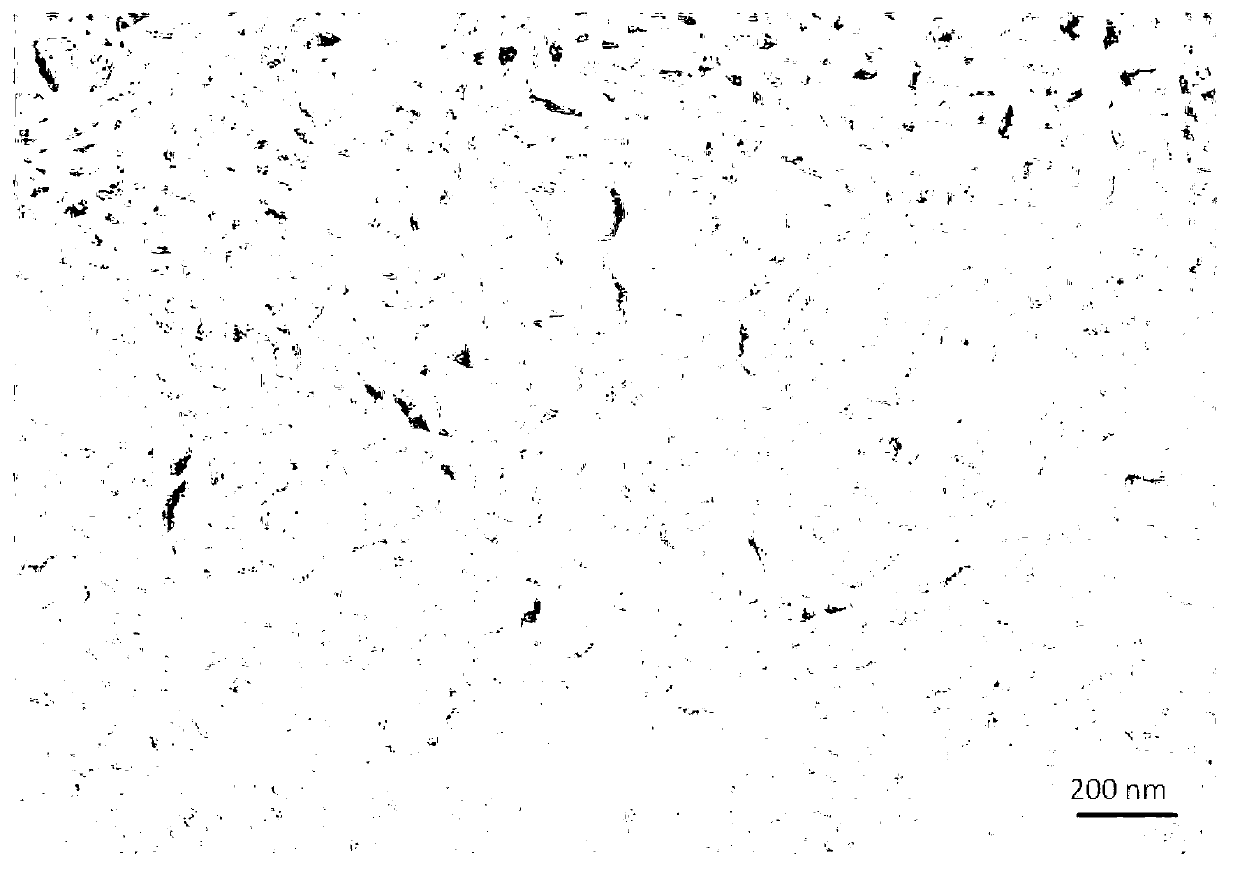

[0039] The product has been tested by X-ray photoelectron spectroscopy ( figure 1 ) identified as MoS 2 , after SEM electron microscope picture ( figure 2 ) Observing the morphology of the product...

Embodiment 2

[0041] A. Take the titanium sheet, put it into concentrated hydrochloric acid and ultrasonically wash it, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0042] B. Prepare 1mol / L Na 2 MoO 4 2H 2 O aqueous solution 15ml, the thioacetamide aqueous solution 15ml of 0.5mol / L, above-mentioned two solutions are mixed, add the deionized water of 8ml again, transfer in the 40ml autoclave after fully stirring to obtain uniform stable solution; The titanium sheet is put into the reaction kettle obliquely. Heat water at 220°C for 24 hours, and cool to room temperature with cooling water after the reaction is complete.

[0043] C. Take out the titanium sheet in the reaction kettle, wash it with deionized water and ethanol, dry it, and dry it at 80° C. for 1 hour to obtain the product.

[0044] The product has passed the SEM electron microscope picture ( Figure 5 ) Observing the morphology of the product, nanosheets with a diameter of 1.6-2...

Embodiment 3

[0046] A. Take the molybdenum sheet, put it into concentrated hydrochloric acid and ultrasonically wash it, then transfer it to deionized water and ethanol, and ultrasonically wash it respectively;

[0047] B. Prepare 0.5mol / L H 2 MoO 4 Aqueous solution 8ml, 0.5mol / L thiourea aqueous solution 8ml, mix above-mentioned two solutions, then add 20ml of deionized water, fully stir to obtain homogeneous and stable solution and then transfer to 40ml autoclave; placed in the reactor. Heat water at 170°C for 24 hours, and cool to room temperature with cooling water after the reaction is complete.

[0048] C. Take out the molybdenum sheet in the reaction kettle, wash it with deionized water and ethanol, dry it, and dry it at 80°C for 1 hour to obtain the product.

[0049] The product has passed the SEM electron microscope picture ( Image 6 ) Observing the morphology of the product, nanosheets with a diameter of 80-200nm and a thickness of 10-20nm grow vertically on the substrate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com