Two-stage cadence braking master valve (type V)

A brake master valve and point brake technology, which is applied in the direction of brakes, brake components, control valves and air release valves, can solve the problems of affecting the braking effect, weak braking force and unsafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

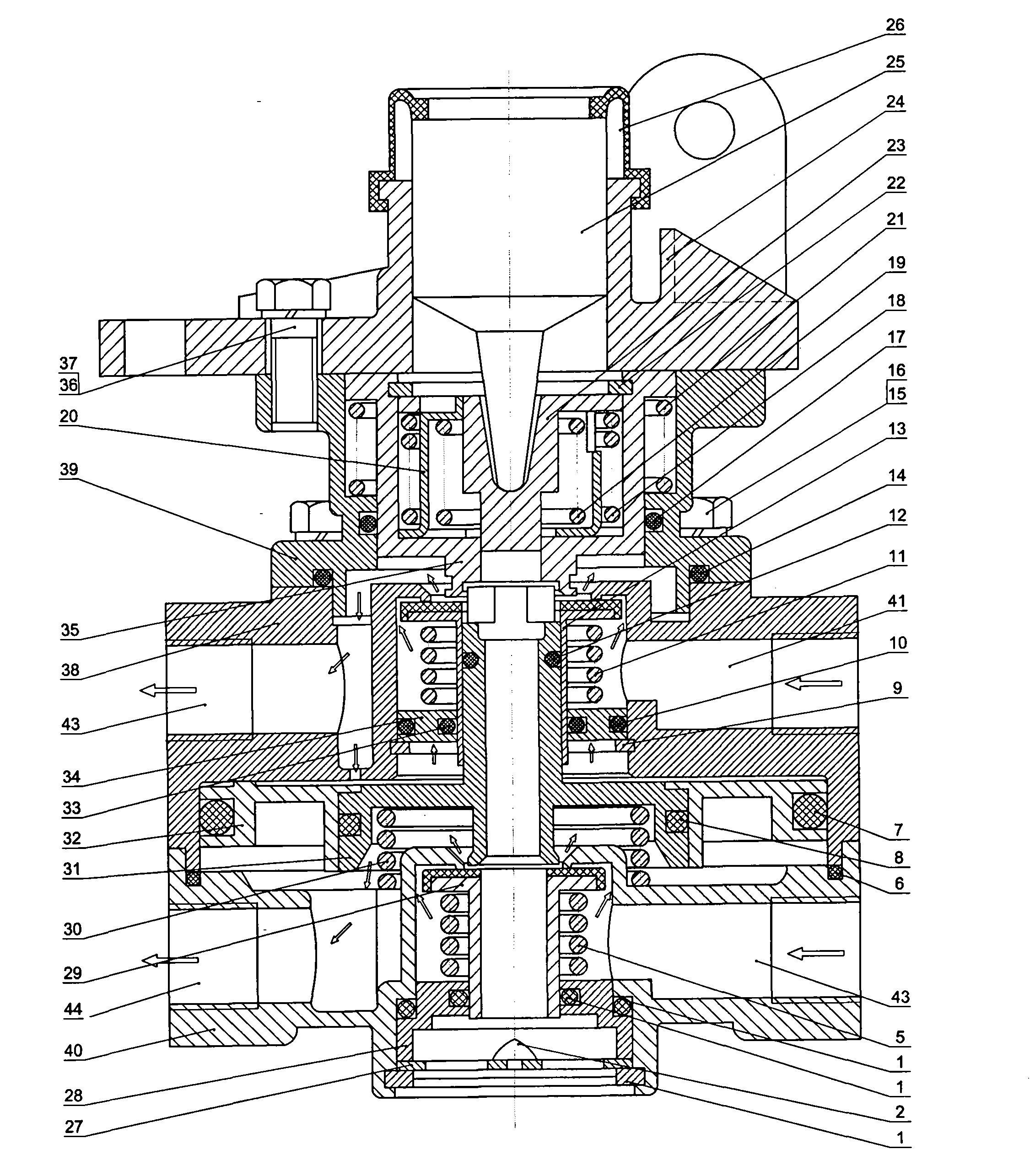

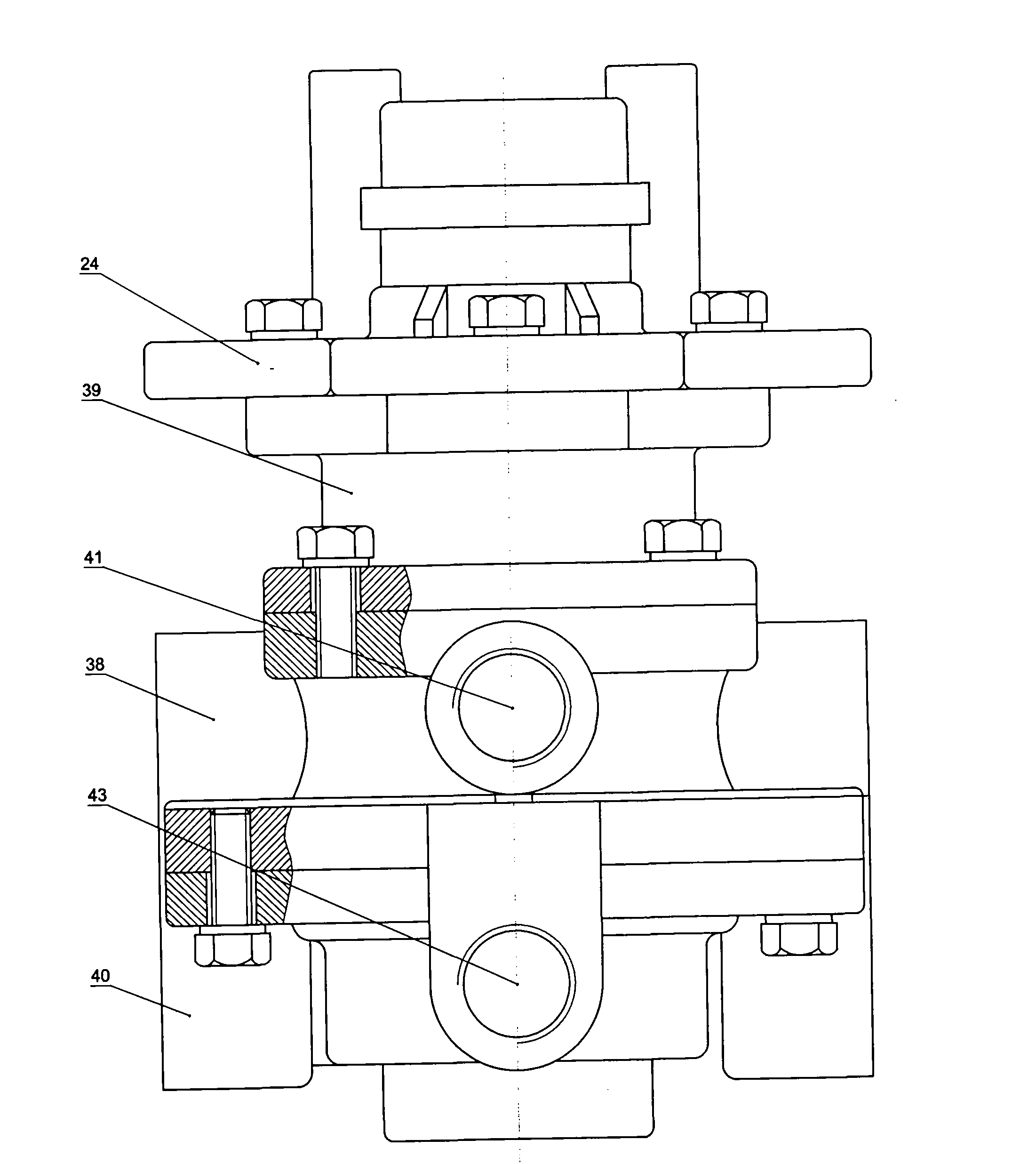

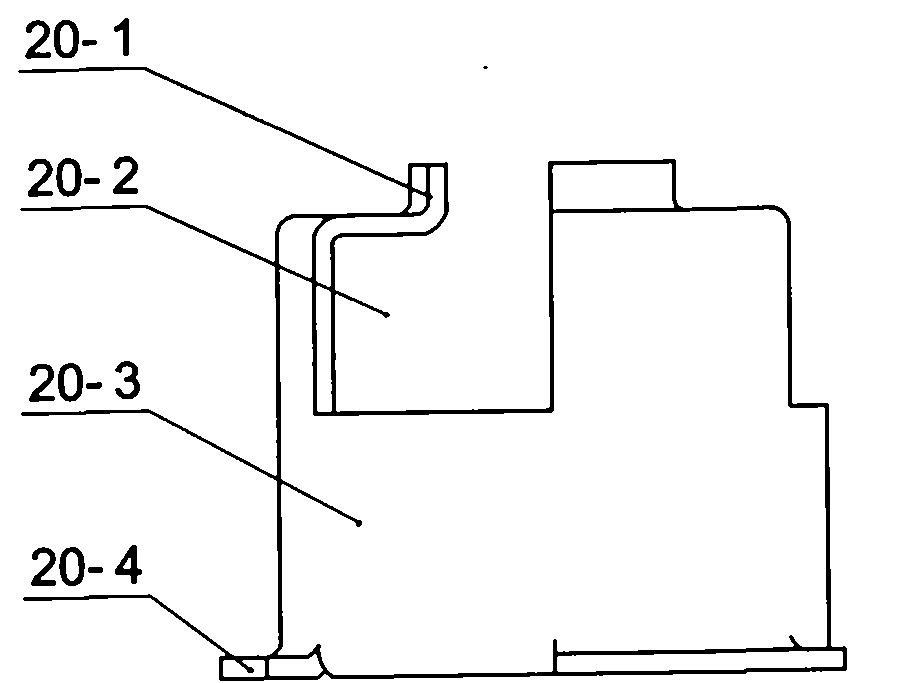

[0027] Embodiment: a two-stage point brake master valve (V type), including an upper valve body 24, a middle valve body 38 and a lower valve body 40, and a piston cylinder 39 is passed between the upper valve body 24 and the middle valve body 38 The connection is sealed and fixed, the upper edge of the lower valve body 40 and the lower edge of the middle valve body 38 are matched and nested and sealed and fixed, and the upper piston assembly and the lower piston assembly are respectively sleeved in the piston cylinder 39 and the middle valve body 38, An annular piston sleeve 32 is sleeved between the middle valve body 38 and the lower valve body 40, and an upper valve assembly and a lower valve assembly are respectively arranged in the piston sleeve 32 and the lower valve body 40; the sides of the middle valve body 38 are respectively An air inlet 41 and three air outlets 43 (two by two perpendicular to each other) are provided, and the side of the lower valve body 40 is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com