Preparation method of melt spinning polyurethane fiber thin denier filament

A fine denier, spandex technology, applied in the direction of single-component polyurethane rayon filament, synthetic polymer rayon filament chemical post-treatment, etc., can solve the problem of low breaking strength, low elastic recovery rate, and influence Fiber physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

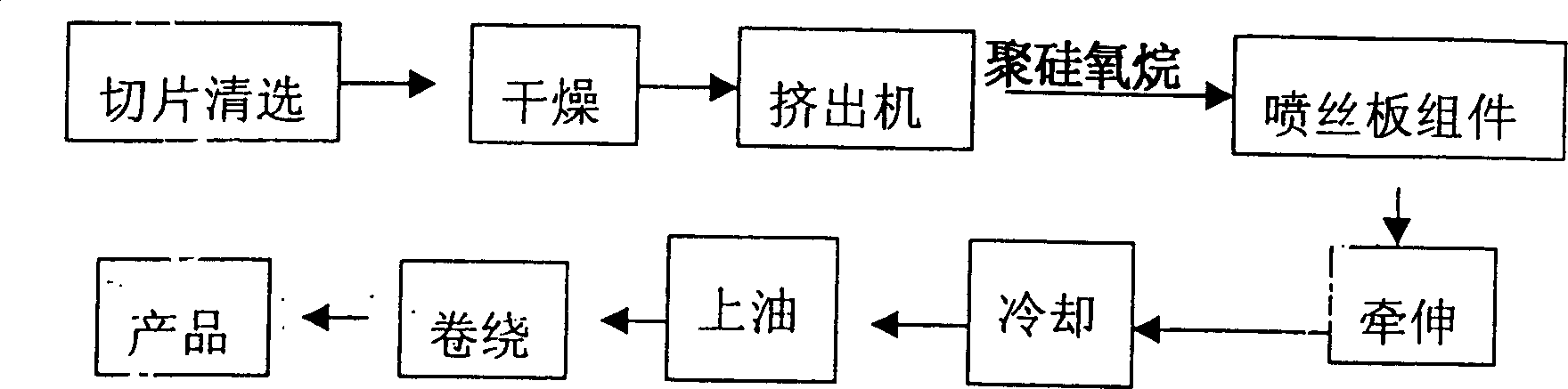

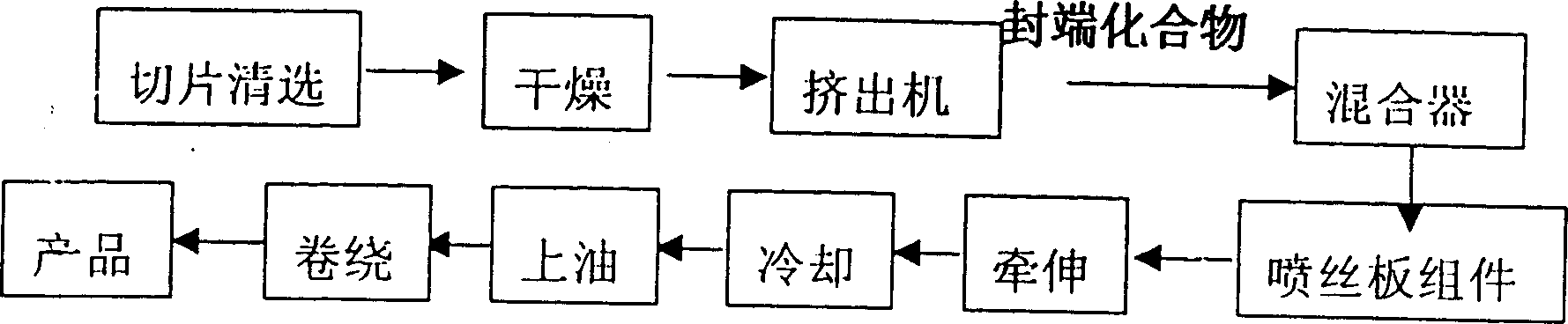

[0018] After the thermoplastic polyurethane chips are cleaned, they are mixed with additives other than the crosslinking agent and dried. The dried materials are put into the screw extruder, melted and mixed, and enter the mixing section in the metering section of the extruder or after exiting the extruder. A certain amount of cross-linking agent is added in front of the machine, and the melt-spun material is sprayed out through the spinneret, and the as-spun yarn is stretched, cooled, oiled, and wound, and the melt-spun fine-denier spandex filament is obtained. The reason why the present invention successfully melt-spun fine-denier spandex filaments is that it solves the problem of supporting the use of cross-linking agents and thermoplastic polyurethanes.

[0019] The supporting use of the cross-linking agent and thermoplastic polyurethane refers to the supporting use of the chemical composition of the cross-linking agent and the composition of thermoplastic polyurethane. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com